A transmission mirror and its application in reducing the risk of backscattered light damage to laser drivers

A technology of mirrors and transmission optical paths, applied in the field of optical components, can solve the problems of unsupported dielectric film technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

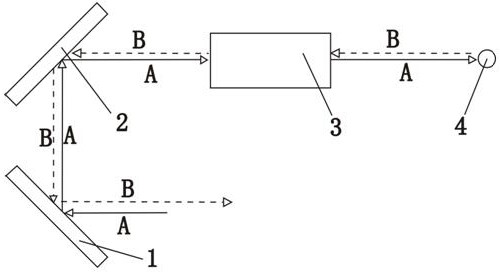

Method used

Image

Examples

Embodiment

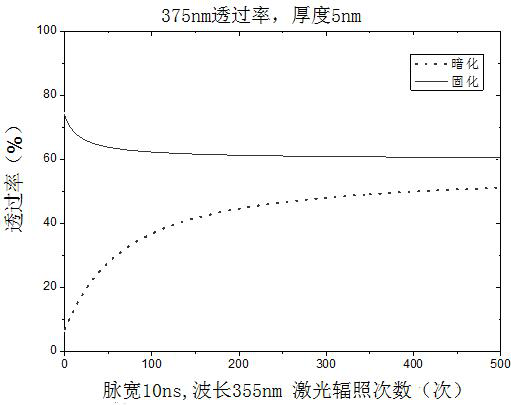

[0030] A transmission mirror prepared by the following method:

[0031]Take a K9 optical material (transmission mirror) with a size of 10mm×10mm×2mm, wash it with acetone and dry it, and then irradiate it with gamma rays at a dose rate of 80Gy / min. The irradiation atmosphere is air, and the total absorbed dose of the glass After the irradiation, the sample was placed in a constant temperature annealing furnace at 300°C for 12 hours and annealed for 12 hours. After testing the optical properties of the material, an optical material with stable color center curing was obtained, and its transmittance was stable around 77.5%.

[0032] The surface of the transmission mirror is then subjected to conventional optical processing;

[0033] Irradiate the transmission mirror after optical processing with 500 rounds of ultraviolet pulsed laser, the pulse width is 10ns, and the energy density is 2J / cm 2 ;

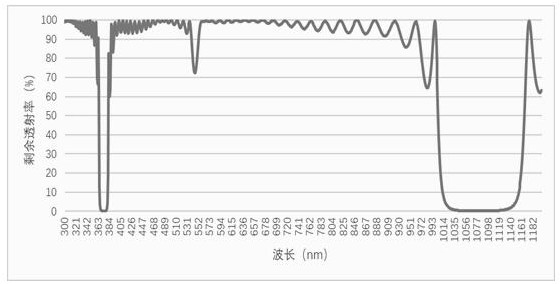

[0034] Coating high-threshold reflective film on the reflective surface cured by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical damage threshold | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com