Variable-curvature focusing light beam lens high-power water-guided laser water-light coupling device

A coupling device and variable curvature technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., to achieve the effects of eliminating gas explosion, improving processing efficiency, and increasing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

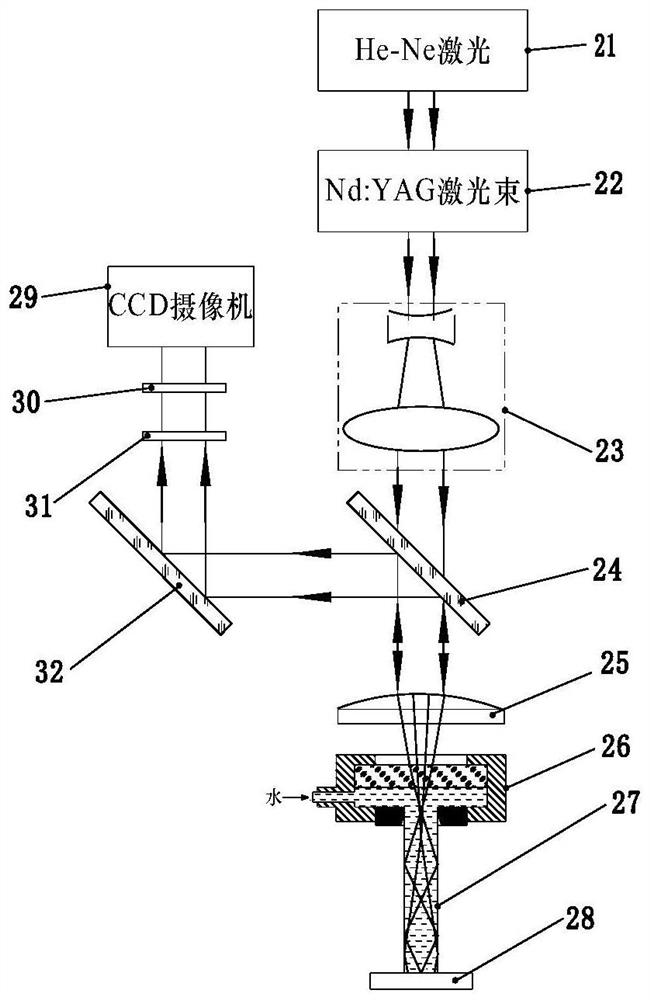

[0020] Such as figure 1 As shown, the high-power water-guiding laser water-optical coupling device with variable curvature focusing optical column lens is composed of variable curvature focusing optical column lens (1), water-optical coupling cavity (2), glass window (3), high-pressure pure water (4 ), water jet nozzle (5), focusing light column (6), light guide water jet water column (7), cylindrical parallel laser beam (8), etc.; variable curvature focusing light column lens (1) is located in the water-optical coupling cavity ( 2) directly above; the water-optical coupling cavity (2) has a cylindrical structure, with a cylindrical cavity inside, and a circular hole (12) is opened in the center of the upper wall of the cavity for the laser beam Injection, a piece of circular plate glass is fixed close to the lower surface of the upper wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com