Reactor and coil assembly thereof

A technology of coil components and reactors, which is applied in the field of inductance, can solve the problems of low coupling coefficient and high voltage loss, and achieve the effect of improving coupling coefficient, reducing voltage loss and improving insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

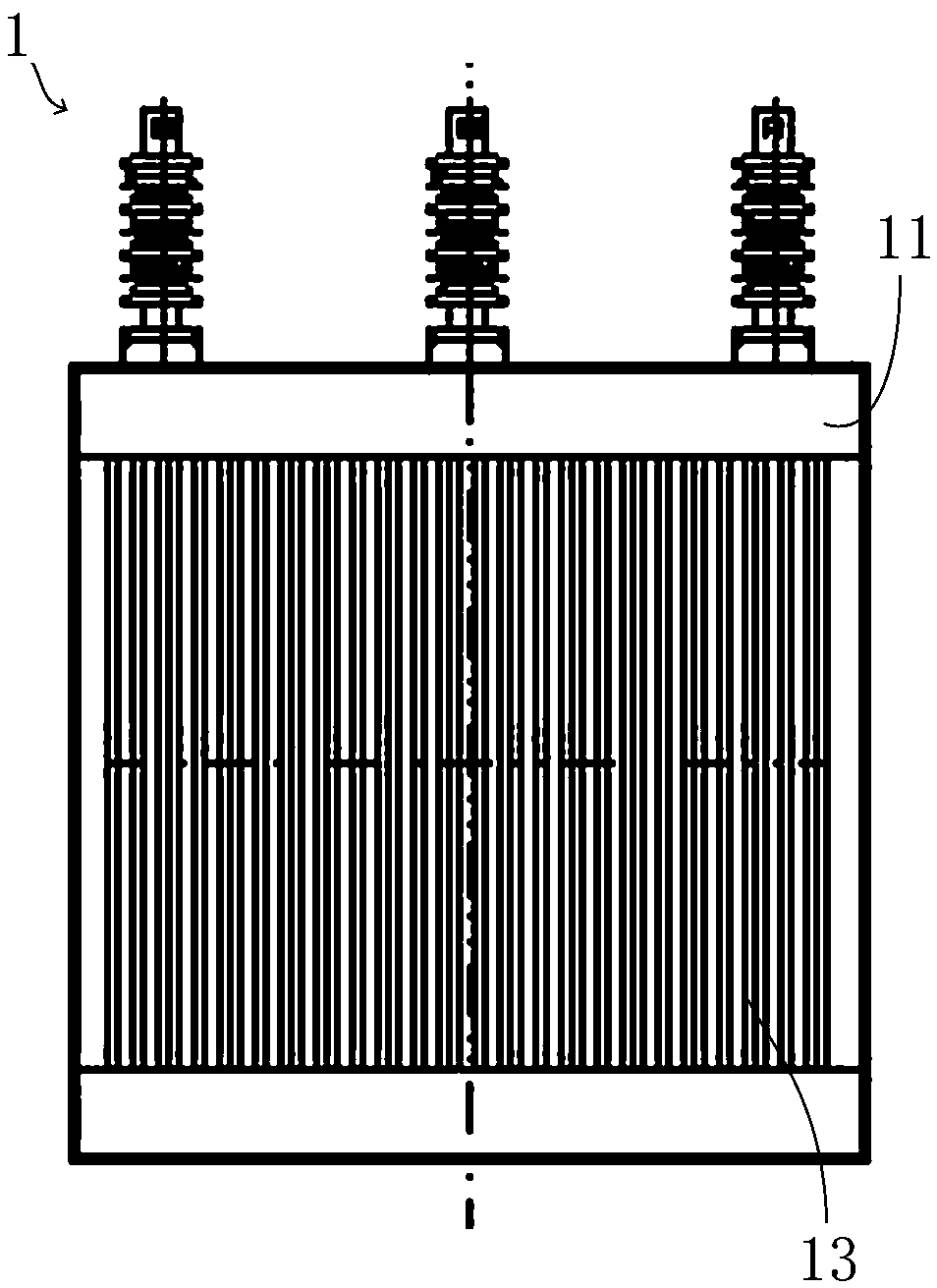

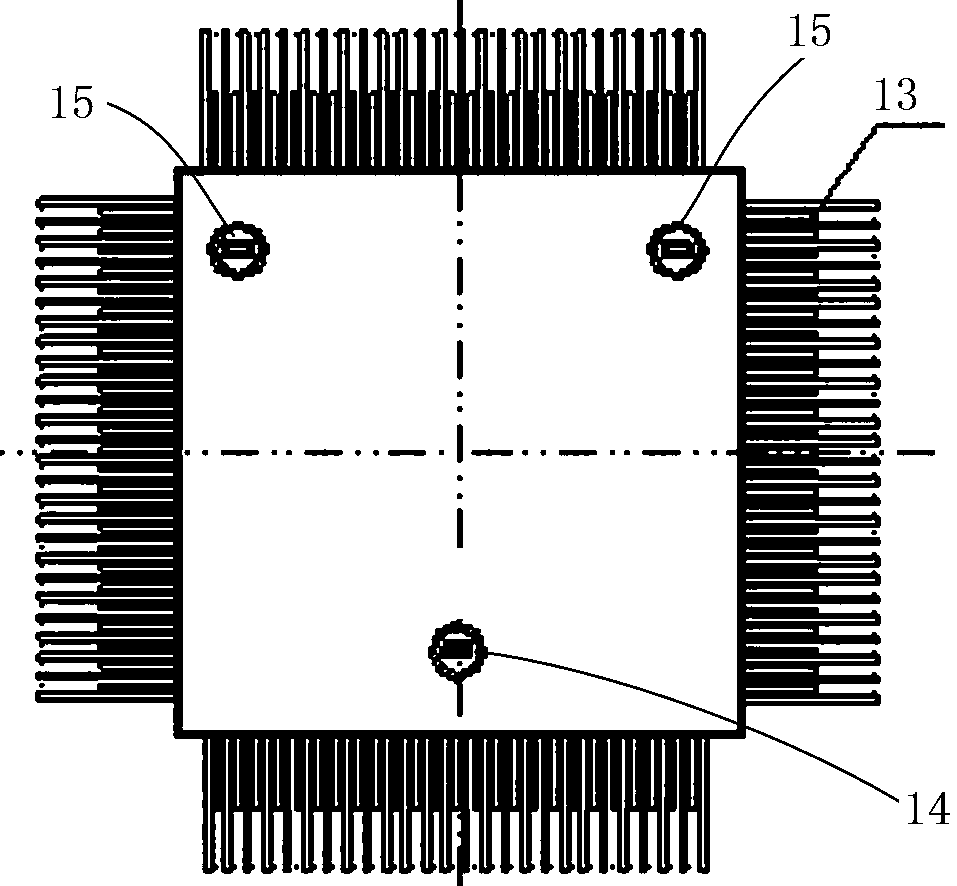

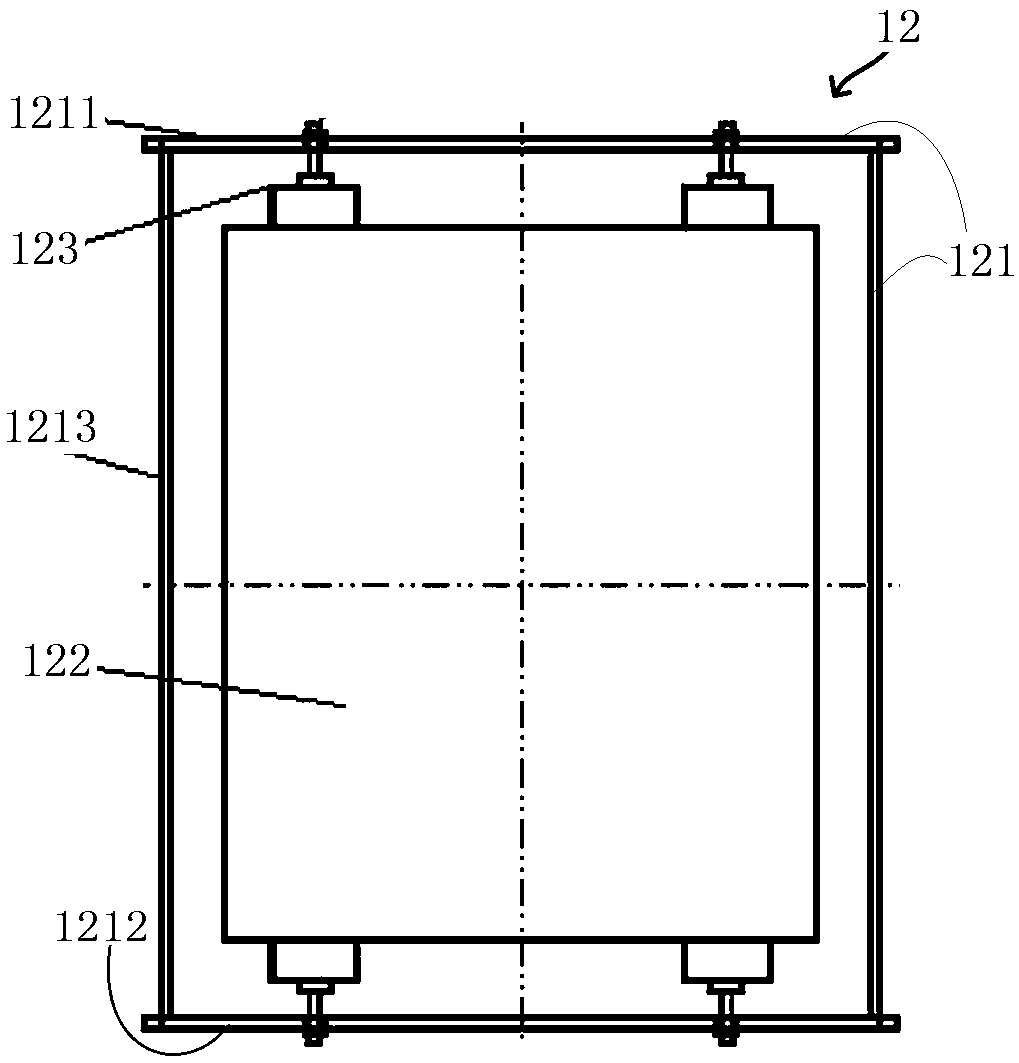

[0044] A specific embodiment of the reactor of the present invention, the reactor 1 of this embodiment is a gas insulated reactor, and the insulating gas adopts sulfur hexafluoride, such as Figure 1 to Figure 2 As shown, the reactor 1 includes a housing 11 and a coil assembly 12 located in the housing 11. The housing 11 is a closed box made of 304 stainless steel, filled with sulfur hexafluoride gas for insulation. The upper part of the housing 11 is provided with three insulating columns, and the outer periphery is provided with cooling fins 13, such as figure 2 As shown, the heat sink 13 includes fins arranged alternately in length, which can enhance the heat dissipation effect. The cooling fins 13 are distributed around the casing 11 . Both the incoming wire terminal 14 and the two outgoing wire terminals 15 of the coil assembly 12 are led out fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com