A control method and device for preventing back-up roll bearing package burnout of finishing mill

A control method and a technology of a control device, which are applied in rolling force/gap control, roll safety equipment, metal rolling, etc., can solve problems such as easy burnout of back-up roll bearing packages in finishing mills, and achieve easy burnout , Prevent indentation defects, and improve productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

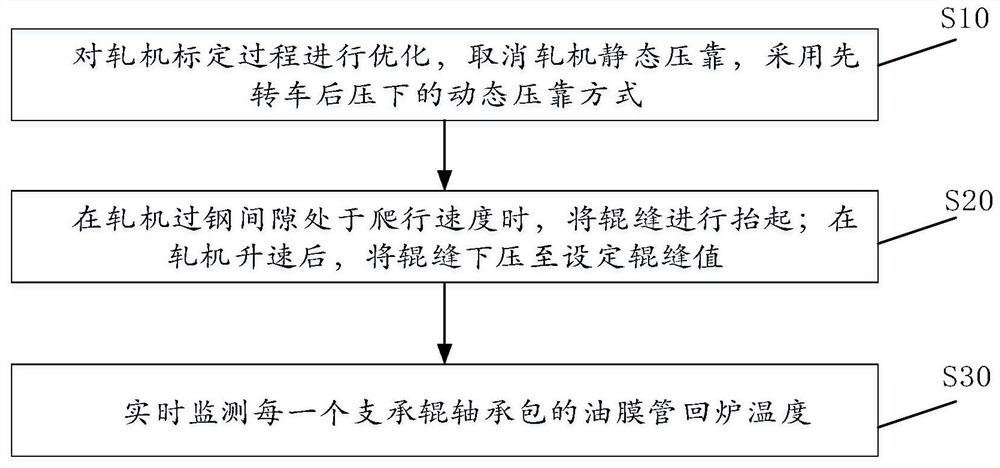

[0037] see figure 1 , an embodiment of the present invention provides a control method for preventing back-up roll bearing package burnout in a finishing mill, including:

[0038] Step S10, optimizing the calibration process of the rolling mill, canceling the static pressing of the rolling mill, and adopting the dynamic pressing method of turning the car first and then pressing down.

[0039] Wherein, in step S10, adopting the dynamic pressing method of turning first and then pressing includes: performing dynamic rotation and pressing of the rolls when turning at a linear speed of 2 m / s.

[0040] Usually, the calibration of the finishing mill usually carries out two static pressings, and the static pressing is performed when the oil film thickness of the back-up roll bearing package has not been fully established, which will easily cause the indentation of the Babbitt alloy. In the embodiment of the present invention, the calibration process of the rolling mill is optimized, ...

Embodiment 2

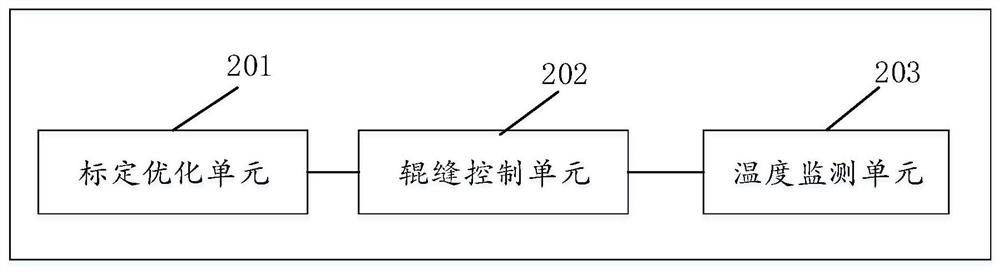

[0049] see figure 2 , the embodiment of the present invention also provides a control device for preventing the burnout of the back-up roll bearing package of the finishing mill. The device is implemented based on the control method for preventing the burnout of the back-up roll bearing package of the finishing mill provided in Embodiment 1. The device includes:

[0050] The calibration optimization unit 201 is used to optimize the calibration process of the rolling mill, cancel the static pressing of the rolling mill, and adopt the dynamic pressing method of turning the car first and then pressing down.

[0051] The roll gap control unit 202 is used to raise the roll gap when the rolling mill passing steel gap is at a creeping speed; after the rolling mill speeds up, press down the roll gap to the set roll gap value.

[0052] Further, the device provided by the embodiment of the present invention also includes:

[0053] The temperature monitoring unit 203 monitors the tempe...

Embodiment 3

[0058] see image 3 , the embodiment of the present invention also provides a computer-readable storage medium 300, the computer-readable storage medium 300 is implemented based on the control method for preventing back-up roll bearing package burnout of the finishing mill provided in the first embodiment, the computer-readable storage medium 300 has stored thereon a computer program 310 which, when executed by a processor, implements the following steps:

[0059] Optimize the calibration process of the rolling mill, cancel the static pressing of the rolling mill, and adopt the dynamic pressing method of turning the car first and then pressing down;

[0060] When the rolling mill passes through the steel gap at the creeping speed, the roll gap is lifted; after the rolling mill speeds up, the roll gap is pressed down to the set roll gap value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com