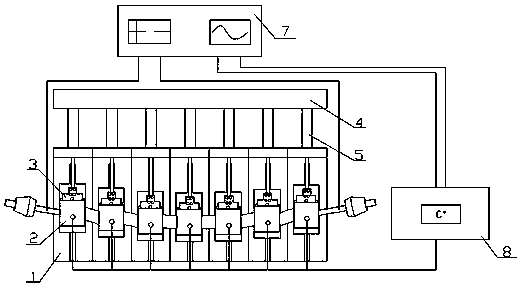

Sectioned shape-control and temperature-control three-dimensional thermal stretch bending forming device

A segmented heat preservation and three-dimensional technology, which is applied in the field of three-dimensional hot stretch bending forming devices, and equipment for hot stretch bending forming of titanium alloy profiles for aircraft or rail trains. It can solve the problems of large heating space, time delay, and no heating and heat preservation devices, etc. problem, to achieve the effect of accurate heating and temperature measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

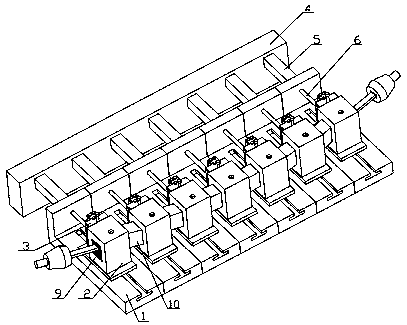

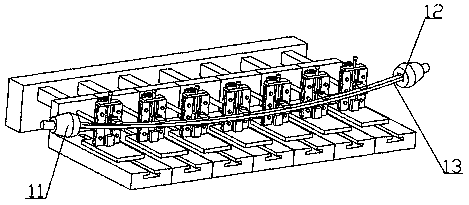

[0027] Embodiment 1, taking the thermal stretch bending of a titanium alloy profile with a rectangular cross-section as an example, the forming process of a three-dimensional thermal stretch bending forming device with segmental shape control and temperature control, the specific steps are as follows:

[0028] In the first step, the target part projects a section of arc on the horizontal and vertical planes, calculates the bending parameters in the horizontal and vertical directions, and determines the number of forming units used, as well as the opening of the asbestos mesh in the segmented incubator Size, calculate the extension length of the piston rod of the hydraulic cylinder;

[0029] The second step is to manually adjust the height limit lever, adjust the height limit pad, install the segmented incubator on the slider guide rail of the forming unit, install the hydraulic cylinder, install the forming unit and the segmented incubator on the base, and The piston rod of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com