Large-sized high-temperature high-strength material vacuum precision casting equipment

A precision casting, high-strength technology, applied in casting equipment, equipment for feeding molten metal into molds, foundry workshops, etc., can solve the problems of occupying vertical distance, not using liquid flow stability, and large mold shell cooling , to achieve the effect of small site requirements, fast heating speed and high casting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

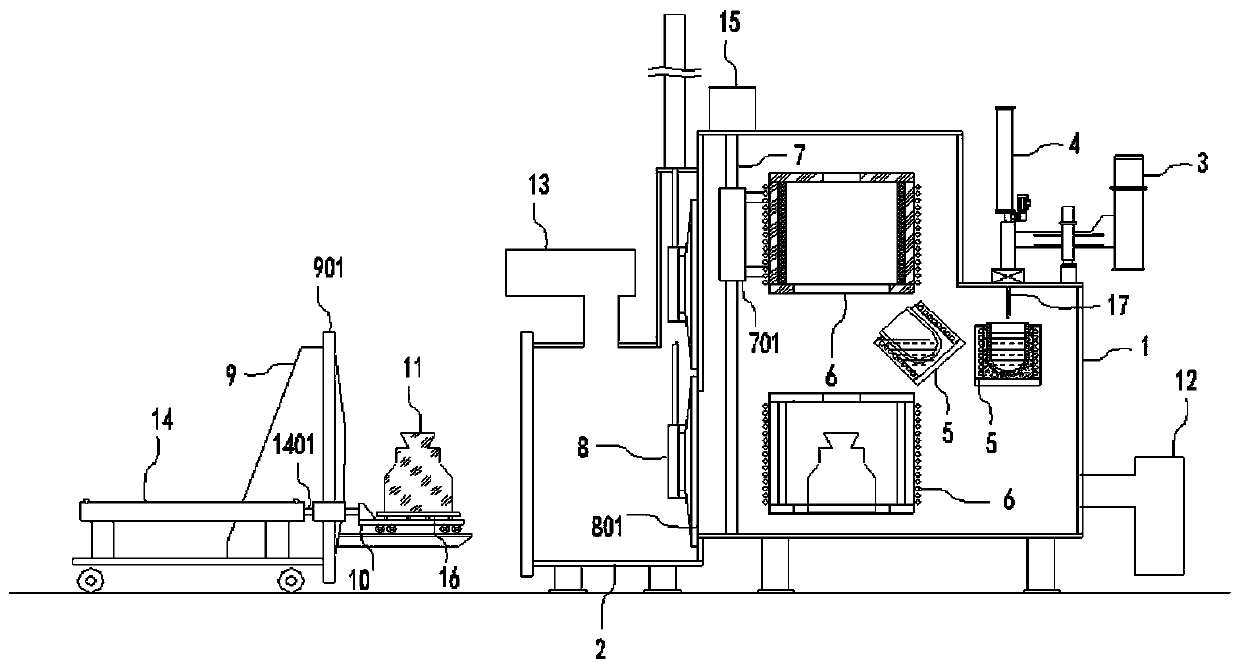

[0018] As shown in the figure, the large-scale high-temperature and high-strength material vacuum precision casting equipment includes melting chamber 1, mold shell chamber 2, melting coil 5, mold shell heater 6, mold shell car 9, melting chamber vacuum system 12 and mold shell chamber vacuum System 13; the smelting chamber 1 and the mold shell chamber 2 are fixedly connected horizontally; a communication port 801 is provided between the smelting chamber 1 and the mold shell chamber 2; the smelting coil 5 and the mold shell heater 6 are placed in the smelting In the chamber 1; a water-cooled isolation valve 8 is longitudinally provided on the upper part of the cavity of the mold shell chamber 2; the water-cooled isolation valve 8 can move longitudinally along the outer wall of the smelting chamber 1 to realize the opening and closing conversion of the communication port 801; A heater elevating mechanism 7 is arranged longitudinally in the cavity of chamber 1; the mold shell hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com