Flame-retardant and antibacterial fabric

A technology of antibacterial fabrics and flame-retardant treatment fluids, applied in the field of fabrics, can solve the problems of fabrics without development prospects, physical injuries of wearers, and inability to guarantee health performance, so as to improve flame resistance and thermal oxygen aging resistance, improve Corrosion resistance, effect of improving wearing comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

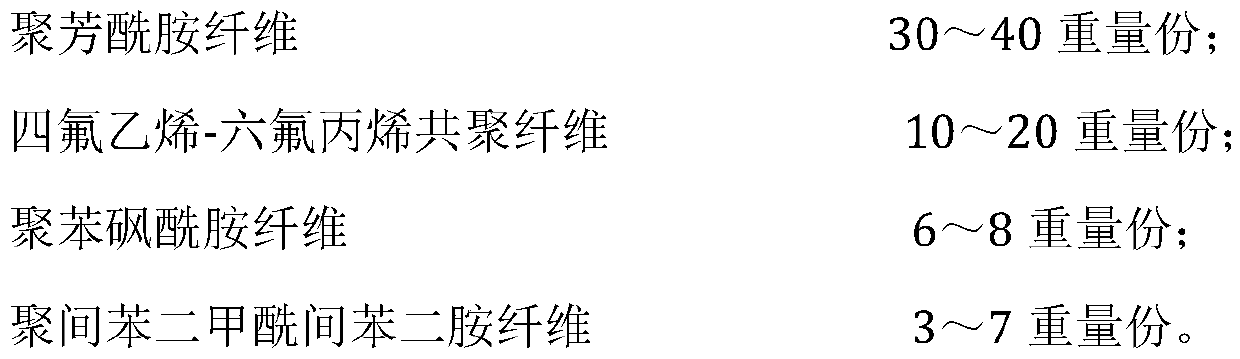

[0047] A flame-retardant and antibacterial fabric, which is obtained by padding a gray cloth with a flame-retardant treatment solution and an antibacterial treatment solution; the gray fabric is made by blending the following raw materials by weight:

[0048]

[0049]

[0050] The flame retardant treatment liquid comprises the following components by weight:

[0051]

[0052] The antibacterial treatment liquid comprises the following components by weight:

[0053]

[0054] The specific operation of padding is: apply the flame retardant treatment liquid and the antibacterial treatment liquid to the gray cloth by padding, then dry the gray cloth padded with the flame retardant treatment liquid and the antibacterial treatment liquid, and then bake it to obtain For flame retardant and antibacterial fabrics, the drying temperature is 130°C for 1 minute, and the baking temperature is 150°C for 4 minutes; the mass ratio of gray cloth to flame retardant treatment solution ...

Embodiment 2

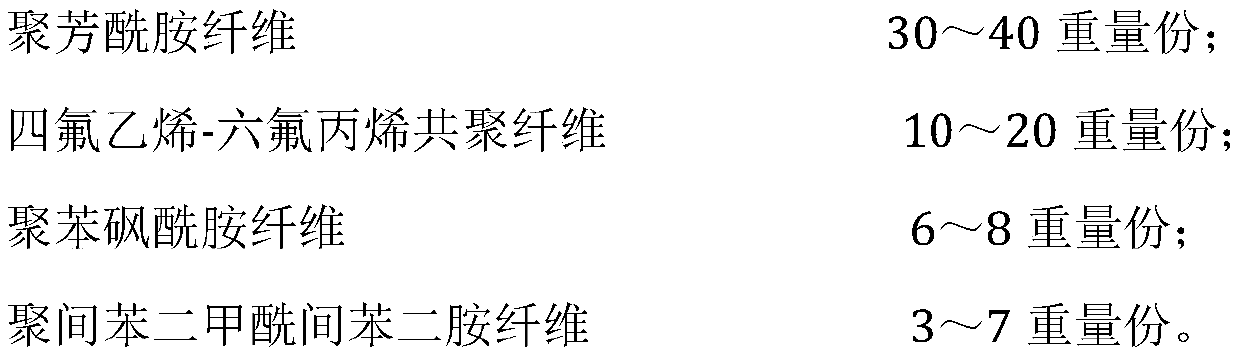

[0056]A flame-retardant and antibacterial fabric, which is obtained by padding a gray cloth with a flame-retardant treatment solution and an antibacterial treatment solution; the gray fabric is made by blending the following raw materials by weight:

[0057]

[0058] The flame retardant treatment liquid comprises the following components by weight:

[0059]

[0060] The antibacterial treatment liquid comprises the following components by weight:

[0061]

[0062] The specific operation of padding is: apply the flame retardant treatment liquid and the antibacterial treatment liquid to the gray cloth by padding, then dry the gray cloth padded with the flame retardant treatment liquid and the antibacterial treatment liquid, and then bake it to obtain For flame retardant and antibacterial fabrics, the drying temperature is 130°C for 1 minute, and the baking temperature is 150°C for 4 minutes; the mass ratio of gray cloth to flame retardant treatment solution is 100:9; gra...

Embodiment 3

[0064] A flame-retardant and antibacterial fabric, which is obtained by padding a gray cloth with a flame-retardant treatment solution and an antibacterial treatment solution; the gray fabric is made by blending the following raw materials by weight:

[0065]

[0066] The flame retardant treatment liquid comprises the following components by weight:

[0067]

[0068]

[0069] The antibacterial treatment liquid comprises the following components by weight:

[0070]

[0071] The specific operation of padding is: apply the flame retardant treatment liquid and the antibacterial treatment liquid to the gray cloth by padding, then dry the gray cloth padded with the flame retardant treatment liquid and the antibacterial treatment liquid, and then bake it to obtain For flame retardant and antibacterial fabrics, the drying temperature is 130°C for 1 minute, and the baking temperature is 150°C for 4 minutes; the mass ratio of gray cloth to flame retardant treatment solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| brittleness temperature | aaaaa | aaaaa |

| Vicat softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com