Surface sizing agent for papermaking and papermaking method for improving paper strength

A surface sizing agent, paper strength technology, applied in papermaking, textiles and papermaking, paper coatings, etc., can solve the problem of not finding, and achieve improved bursting strength and folding endurance, high compressive strength, and tensile strength. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

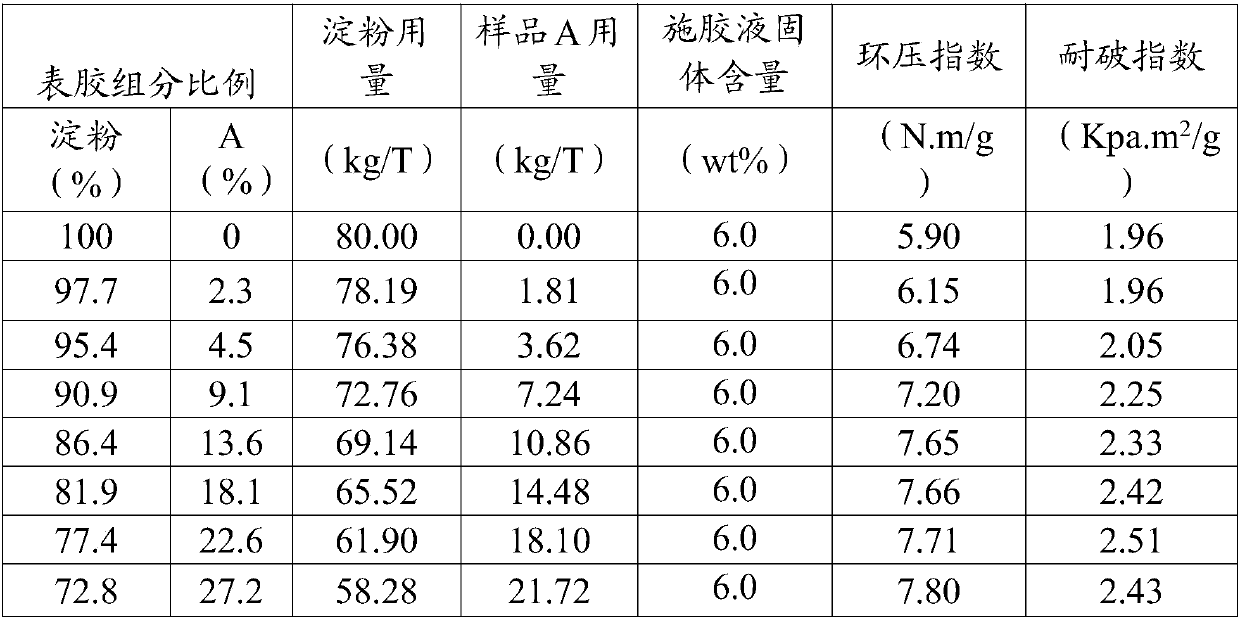

[0074] Example 1 Application of Sample A to Substitute Surface Adhesive Starch in the Production of Corrugated Paper with OCC Raw Materials

[0075] 1. Materials

[0076] The starch is corn starch or tapioca starch from Dongguan Perfect Starch Co., Ltd.; the base paper is from Dongguan Xufeng Paper Co., Ltd., which is 100% OCC waste-produced corrugated paper (Polywa, without sizing).

[0077] 2. The surface sizing method and test steps are as follows:

[0078] 1. Take a 1000ml beaker, weigh 940.0g deionized water in the beaker, and put it into a 95°C magnetic water bath stirrer, add 60.00g starch under stirring, and then add 0.024g potassium peroxodisulfate (starch Viscosity reducer, consumption is 0.04% relative to the amount of starch), and then the beaker is covered with a watch glass of suitable size, and the timing is started for 60 minutes. After the timing ends, the starch is put into a 62.2°C water bath and cooled to 62.2°C to obtain 6 % starch solution, save for fut...

Embodiment 2

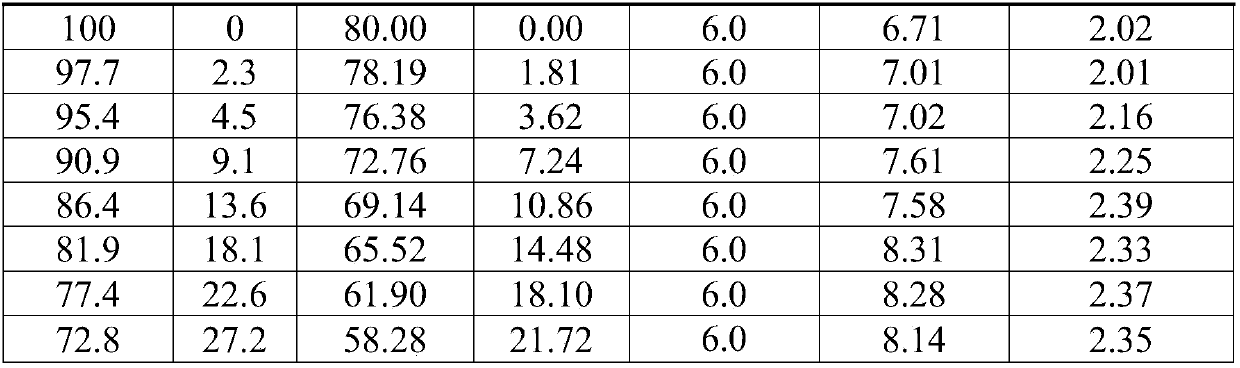

[0099] Example 2 Influence of the Substitution Rate of Sample C Substituting Starch on Paper Strength

[0100] 1. Materials:

[0101] The starch is corn starch from Dongguan Perfect Starch Co., Ltd.; the base paper is from Dongguan Xufeng Paper Co., Ltd., which is 100% OCC waste-produced corrugated paper (Powa, without sizing).

[0102] Two, surface sizing method and experimental procedure are the same as embodiment 1.

[0103] 3. Experimental results

[0104] The test results are shown in Table 3. It can be seen from the results in Table 3 that with the increase of the replacement rate of sample C, the ring pressure index and burst strength of the paper increased significantly, and when the replacement rate was 30-40%, both the ring pressure index and the burst strength reached the highest value; With the increase of sample C, the ring pressure index and burst strength gradually decreased.

[0105] Table 3 Effect of the mixing ratio of starch and sample C on the ring pres...

Embodiment 3

[0107] Example 3 Effect of addition amount of samples F and G and solid content of sizing solution on surface sizing

[0108] 1. Materials:

[0109] The starch is corn starch from Dongguan Perfect Starch Co., Ltd.; the base paper is from Dongguan Xufeng Paper Co., Ltd., which is corrugated paper produced by 100% OCC waste.

[0110] 2. The steps of the surface sizing method are as follows:

[0111] 1. Cooking starch: Take a 1000ml beaker, weigh 800.0g deionized water in the beaker, and put it in a 95°C magnetic water bath stirrer, add 200.00g starch while stirring, and then add 2.0g potassium disulfate (starch viscosity reducer, consumption is relative to 1.0% of starch consumption), then with the suitable size watch glass, beaker is covered, start counting 60 minutes, put starch into 62.2 ℃ of water baths and cool down to 62.2 ℃ after timing finishes, make Get 20% starch solution and save it for later use.

[0112] 2. Preparation of dispersions of samples F and G: Take a ce...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap