Integrated operation system of small workover rig

A technology of operation system and well rig, which is applied to drilling equipment, earthwork drilling, drill pipe, etc., and can solve problems such as low degree of automation and high labor intensity of workover operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

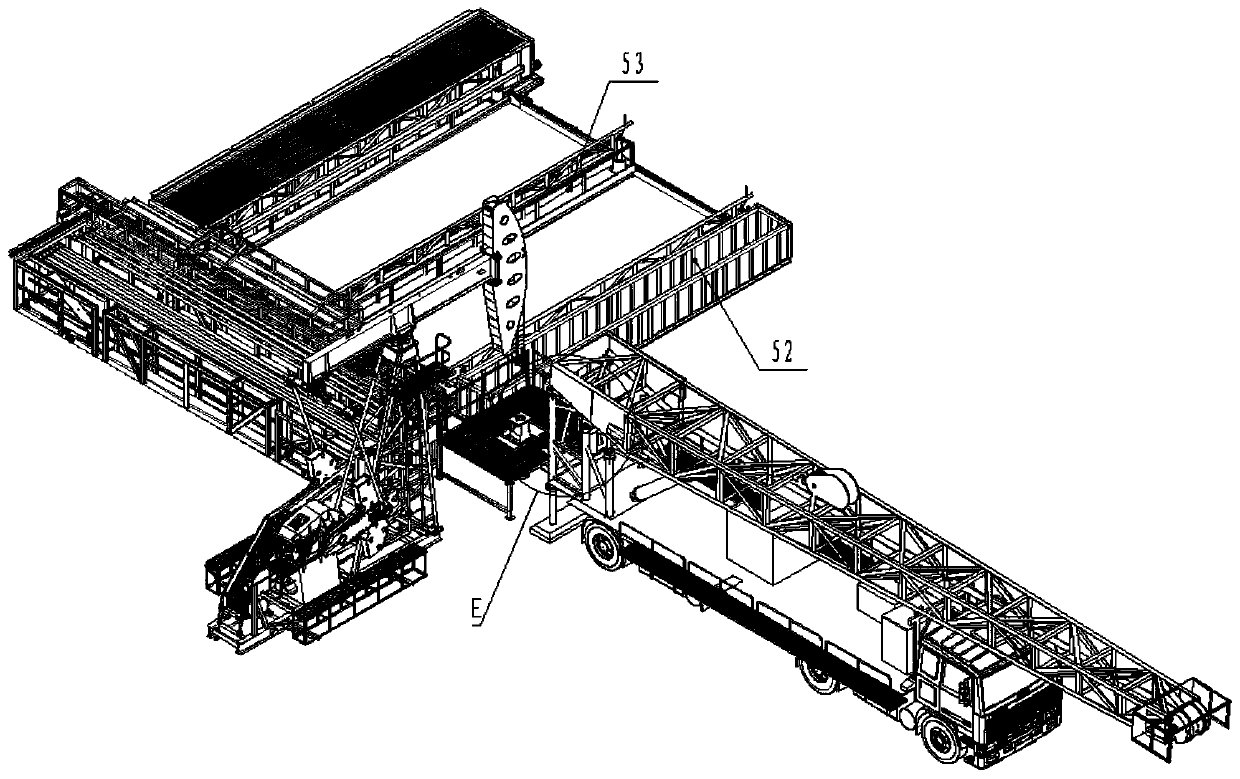

[0054] Minor workover and workover rig integrated operation system, such as figure 1 It includes a wellhead operation module, a pipe rod delivery module 52, and a pipe rod storage module 53, wherein the wellhead operation module is integrated on the loading vehicle in this embodiment. The wellhead operation module includes a pipe-supporting mechanical arm and a hydraulic pipe rod tong located below the pipe-supporting mechanical arm; the pipe-supporting mechanical arm is used to push pipe rods; The pliers body 40, the outer side of the hydraulic pliers body 40 is fixed with a second mounting plate 42, the driving device 43 is fixed on the second mounting plate 42, and the driving device 43 is used to drive the shift switch 41 in different gear positions Action between them; the top of the hydraulic pliers body 40 is fixed with two second guide plates 50, and the two second guide plates 50 are respectively located on both sides of the notch end of the hydraulic pliers body 40, ...

Embodiment 2

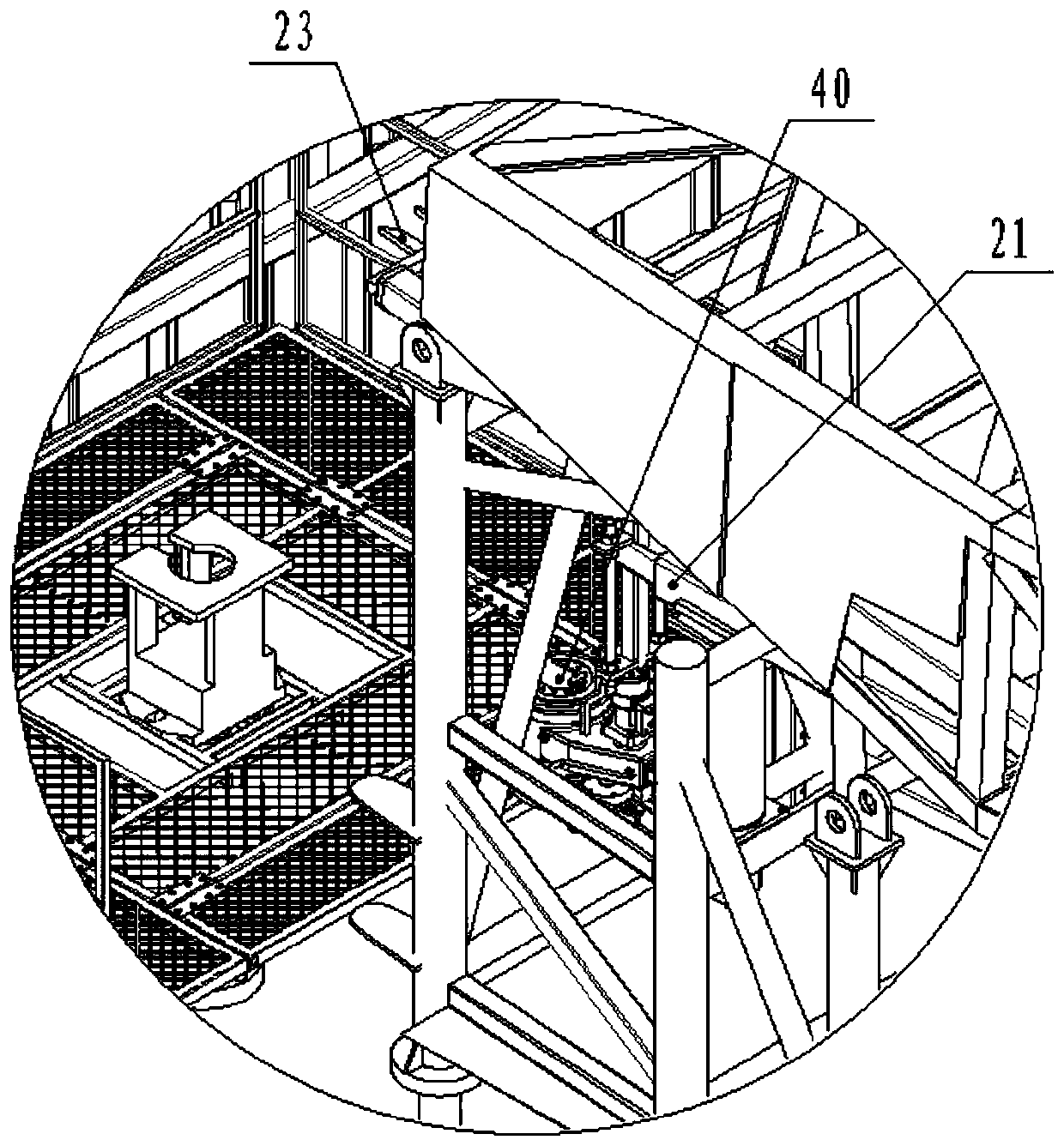

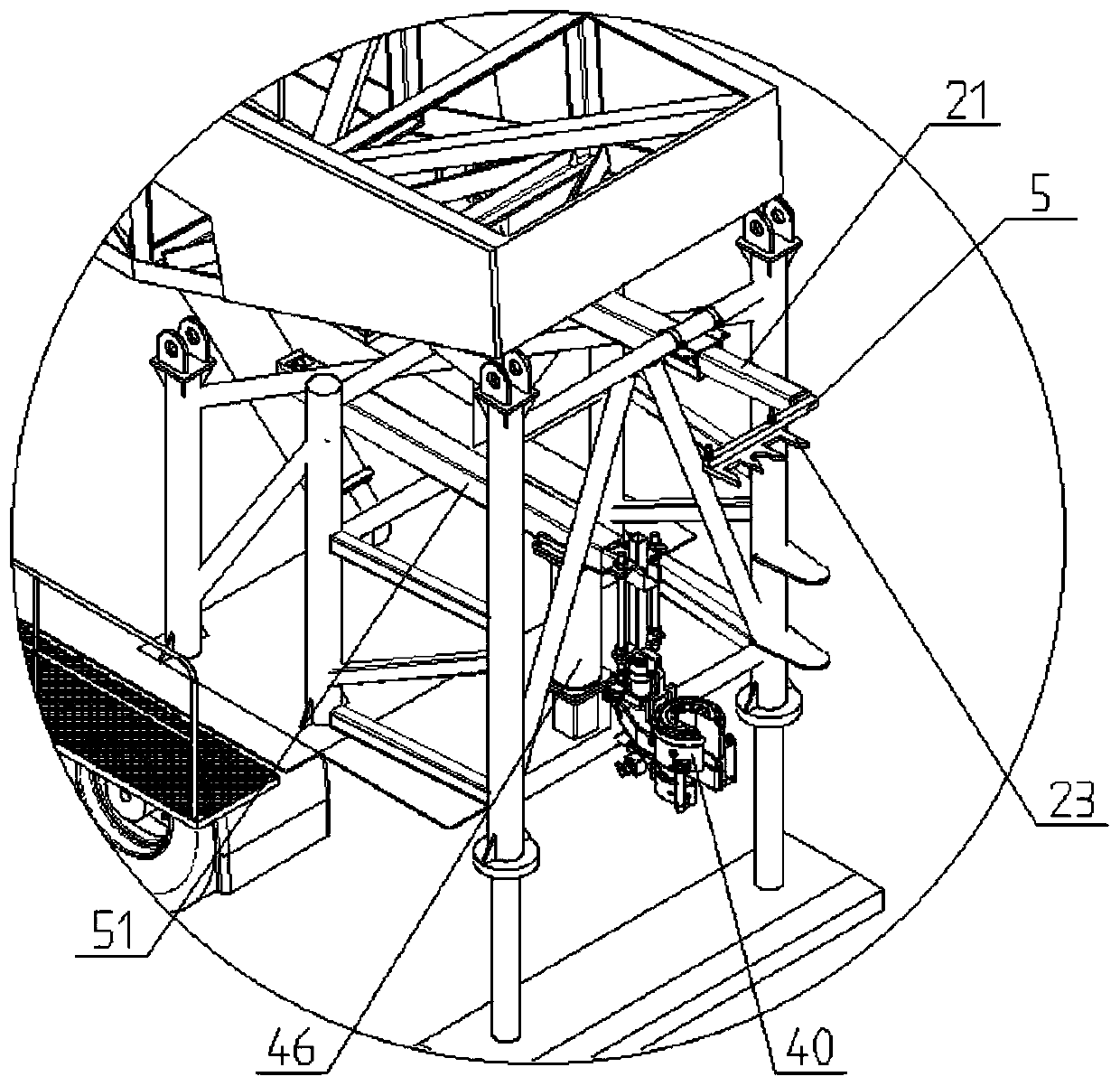

[0056] In the integrated operation system of minor workover and workover rigs, on the basis of Embodiment 1, the pipe supporting mechanical arm includes a linear driving device 21, the driving direction of the linear driving device 21 is horizontal, and the driving end of the linear driving device 21 is connected to the pipe supporting device. Handle 25, the push piece 23 is fixedly connected to the handle 25 of the pipe support, one side of the push piece 23 is open, the open side of the push piece 23 is away from the direction where the handle 25 of the pipe support is located, and the push piece 23 is also included The core bushing mechanism 26 inside, the axis of the core bushing mechanism 26 is vertical, the side of the core bushing mechanism 26 away from the direction where the pipe support handle 25 is located is provided with a semicircular gap 27, and the centering permanent magnet 24 is set under the core bushing mechanism 26 . The linear drive device 21 is a telesco...

Embodiment 3

[0061]In the integrated operation system of minor workover and workover rigs, on the basis of any of the above-mentioned embodiments, the pipe support handle 25 and the driving end of the linear drive device 21 are detachably connected by bolts. The centralizing permanent magnet 24 is fixed inside a magnetic metal block, and the magnetic metal block is fixedly connected with the handle 25 and the pusher 23 of the supporting pipe at the same time. It is convenient to flexibly adjust the connection position of the pipe support handle, and it is convenient to ensure the alignment between the core bushing mechanism and the wellhead according to different well site conditions. The centralizing permanent magnet is isolated and protected by the magnetic metal block, and at the same time, the magnetic metal block will be magnetized by the centralizing permanent magnet, thereby increasing the magnetic field strength and improving the ability to prevent the pipe rod from bouncing back. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com