Delay automatic closing piece and gas self-closing valve with timing closing function

A gas self-closing valve and automatic closing technology, which is applied in the direction of functional valve types, engine components, valve devices, etc., can solve the problems of increasing input costs and actual installation costs, increasing gas pipeline safety hazards, and electronic devices cannot be directly installed. , to achieve the effect of high practical value, flexible use, and elegant appearance design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

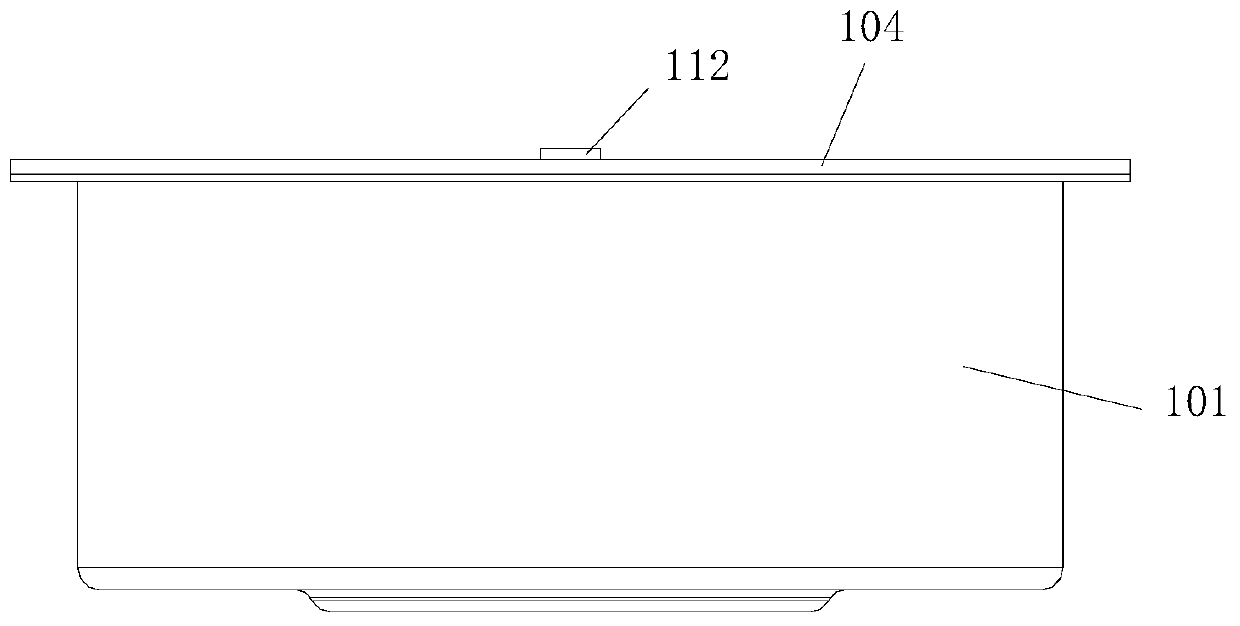

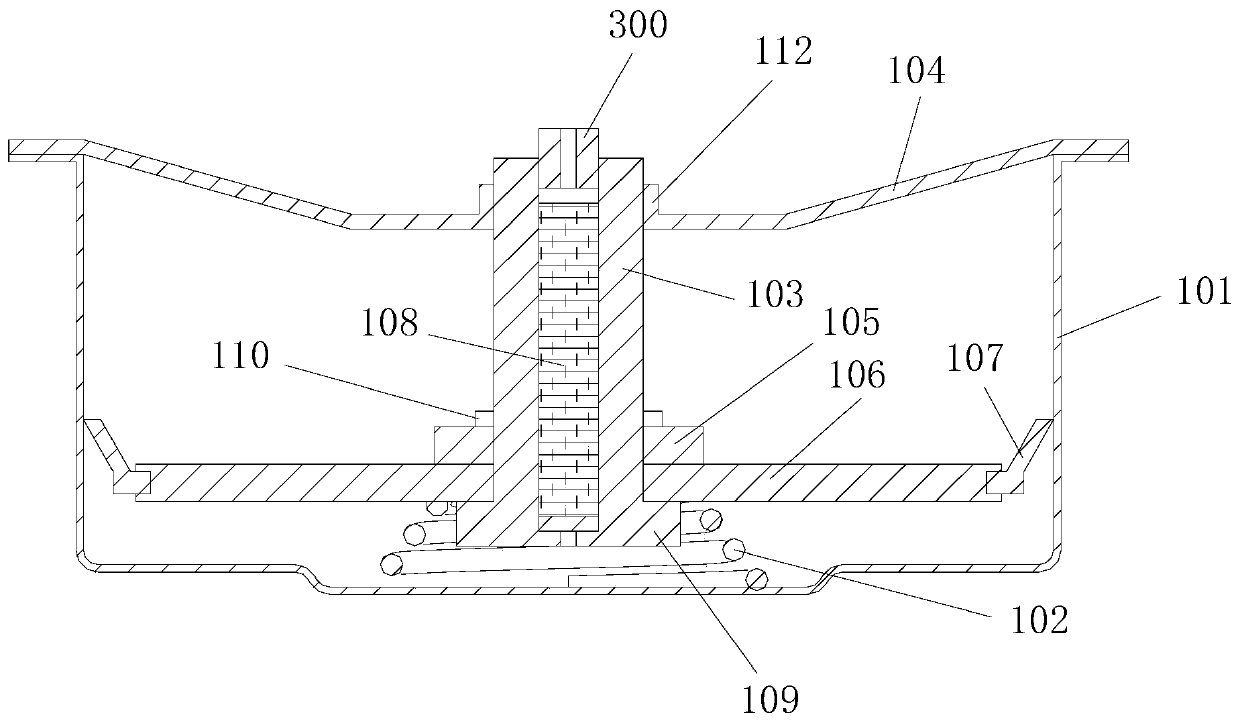

[0090] Such as figure 1 , figure 2 The time-delayed automatic closing member shown includes a casing 101 with an upper opening, a blocking-type moving part arranged in the middle of the inner side of the casing 101 and capable of moving up and down along the central axis of the casing 101, and arranged in the casing 101 and driving The up-moving driving part for the blocking-type moving part to move upward and the compression spring 102 for pushing the blocking-type moving part to move upward along the central axis of the housing 101, the blocking-type moving part, the moving-up driving part Both the member and the compression spring 102 are arranged coaxially with the housing 101.

[0091] The inner cavity of the housing 101 is divided into an upper cavity and a lower cavity directly below the upper cavity by the blocking type moving part, and the blocking type moving part is for the upper part of the lower cavity. A moving part that seals and can move up and down in the c...

Embodiment 2

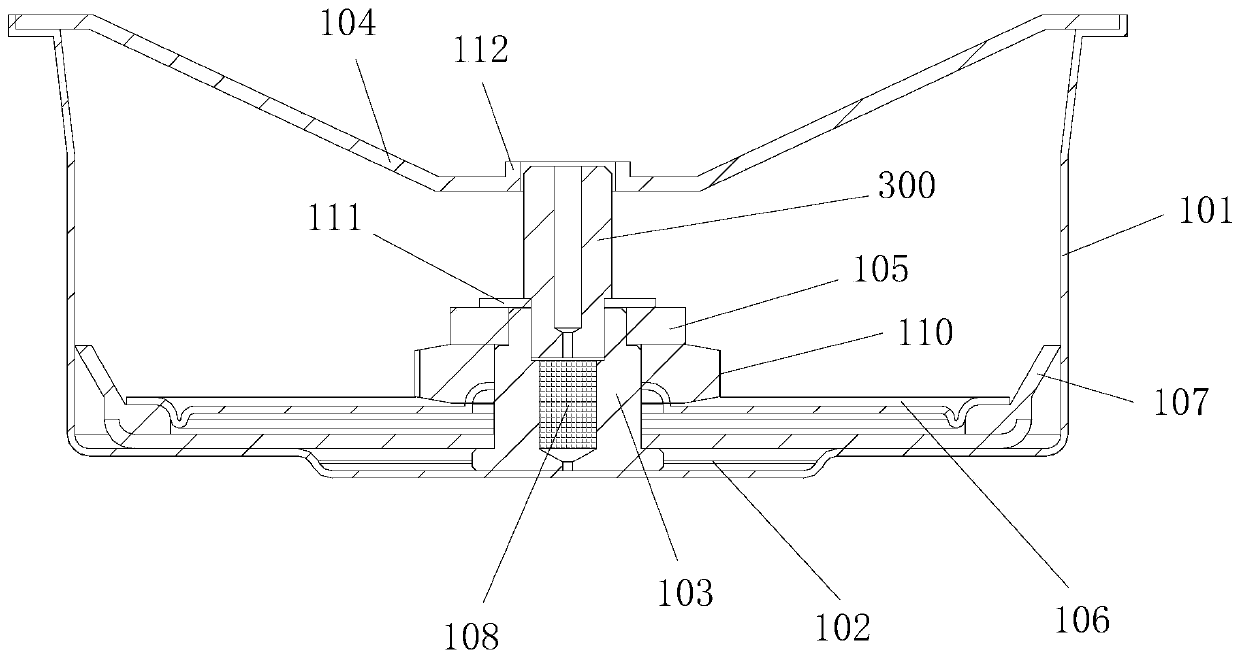

[0150] Such as image 3 As shown, in this embodiment, the difference from Embodiment 1 is: the guide hole for installing the push rod 300 is opened in the middle of the push armature 104; the push rod 300 is coaxially installed in the guide hole.

[0151] The guide sleeve is a guide member for guiding the push rod 300 . The top end of the push rod 300 is located in the guide hole or above the push armature 104 .

[0152] For simple and reliable fixing, the moving plate and the pushing column 103 are locked and fixed by a lock nut 110, and the locking nut 110 is coaxially sleeved on the pushing column 103 and is located above the moving plate;

[0153] The moving plate is fastened and fixed between the locking nut 110 and the limiting ring 109 .

[0154] In this embodiment, the push magnet 105 is located above the locking nut 110;

[0155] The pushing column 103 is provided with an upper limiting member 111 for limiting the pushing magnet 105 , and the upper limiting member ...

Embodiment 3

[0158] Such as Figure 4 A gas self-closing valve with a timing closing function is shown, comprising a self-closing valve body with an air inlet 3 and an air outlet 17, the bottom of the self-closing valve body has a lower opening, and the outer side of the lower opening is The time-delay automatic closing member is installed, and the housing 101 of the time-delay automatic closing member is a blocking member for blocking the lower opening;

[0159] A small film 201 is installed in the valve body of the self-closing valve, a large film 202 is installed on the lower opening, and the small film 201 is positioned above the large film 202; the small film 201 covers the inside of the self-closing valve body The cavity is divided into upper and lower cavities and the upper and lower cavities are respectively the upper valve cavity and the middle valve cavity. The push armature 104 of the delay automatic closing part is located under the large membrane 202 and the cavity between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com