Filling and tamping test box of gangue and gangue filling, pushing and tamping method

A test chamber and gangue technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., to achieve the effects of convenient processing, cost saving and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

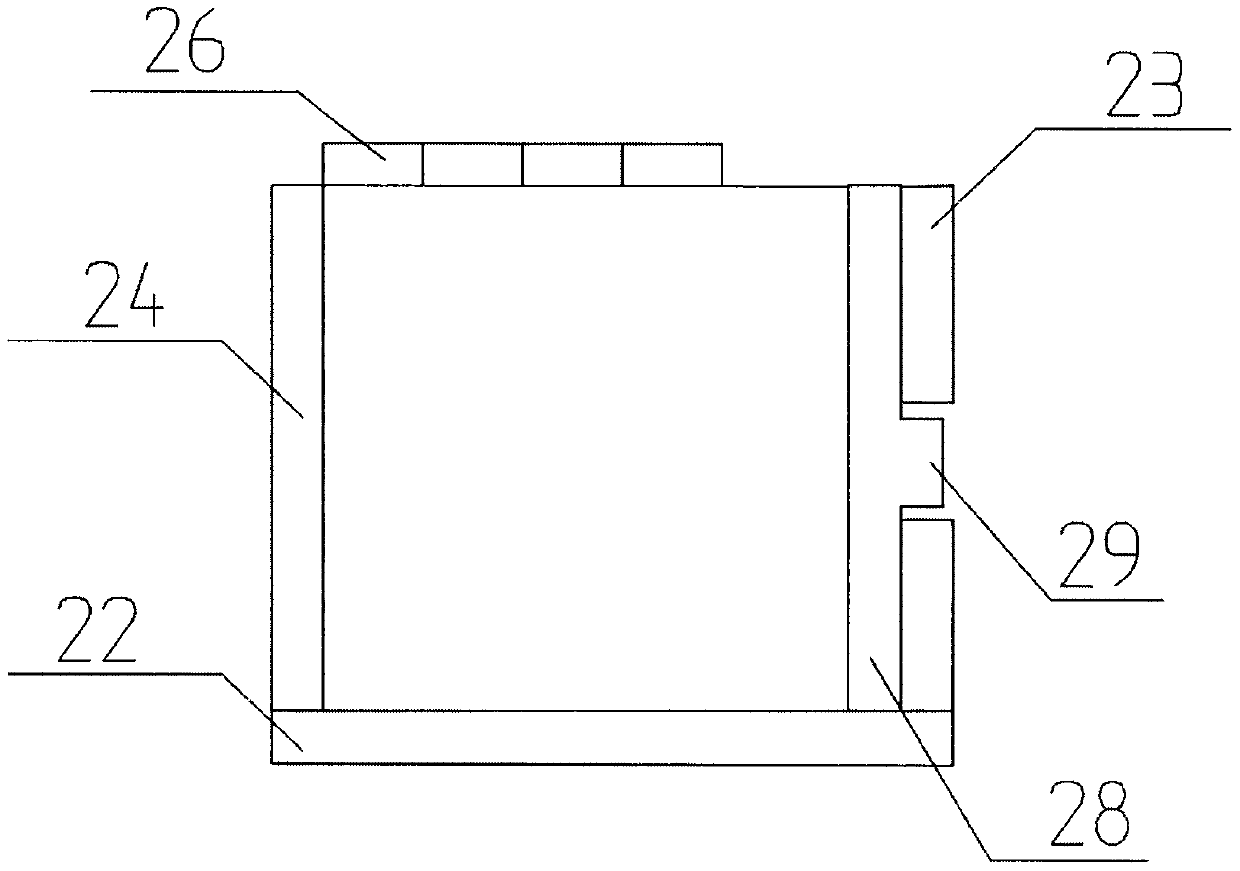

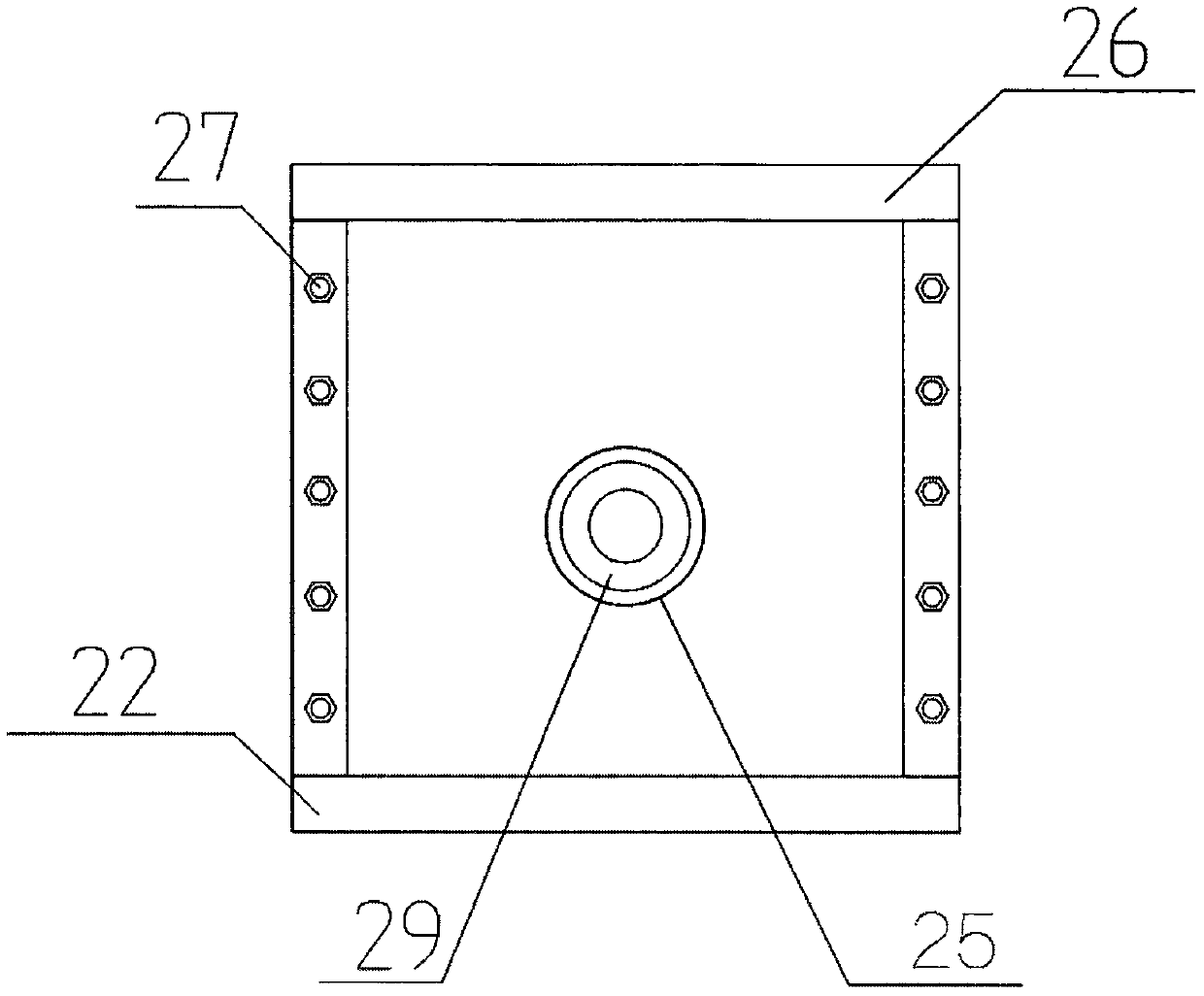

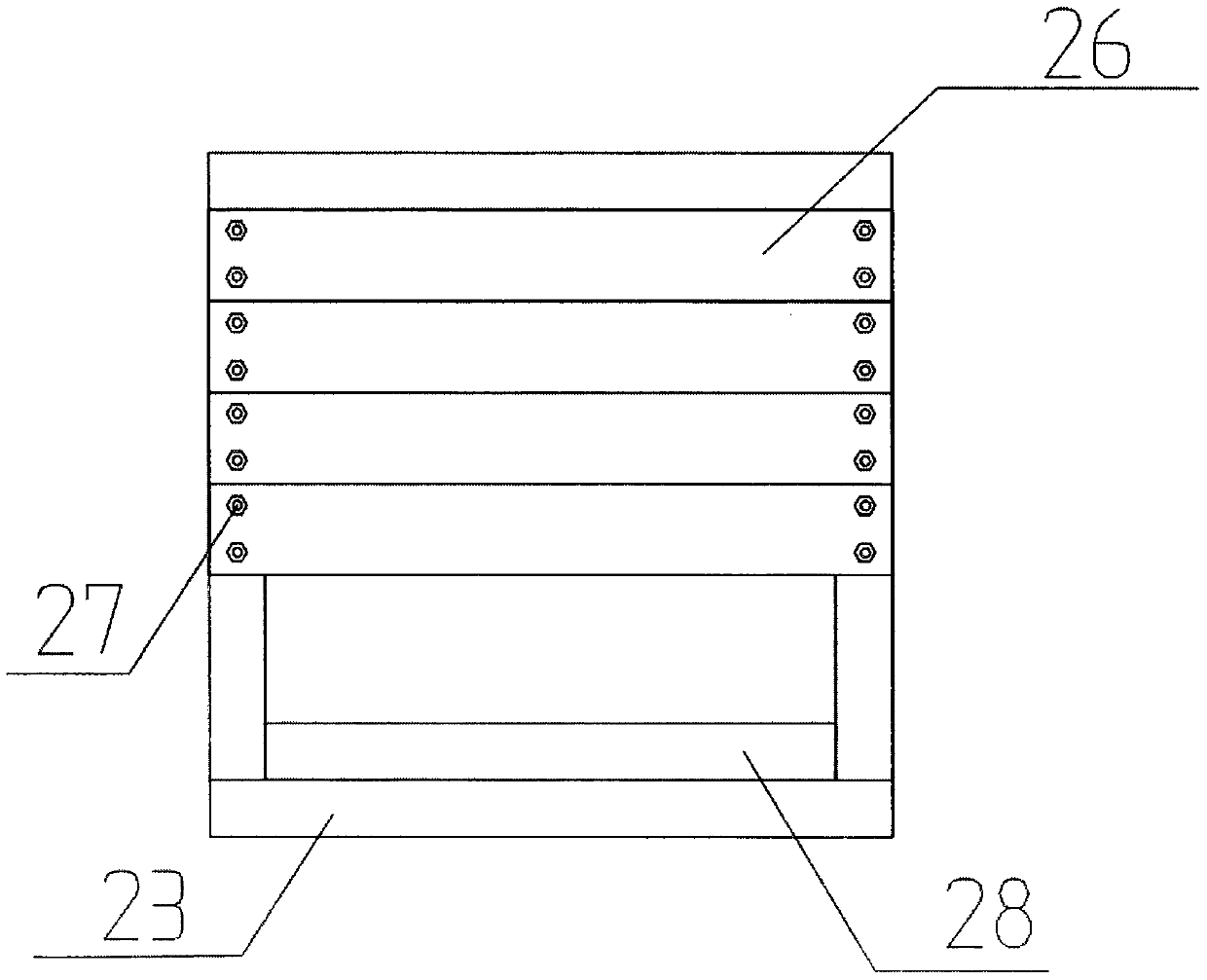

[0015] Such as Figure 1-3 Shown is a schematic structural view of the gangue filling push-tamping test chamber of the present invention.

[0016] A kind of waste rock filling pushing and compacting test box, the test box includes a bottom plate 22 fastened and fixed by screws, a front plate 23, a rear plate 24 and left and right side plates, and a circular hole 25 is arranged in the middle of the front plate 23; in order to facilitate the removal of the top plate, It is convenient to maintain and repair the objects inside the box. The top plate of the compaction box is composed of multiple detachable steel bars 26, simulating the unsinkable roof in the goaf. The detachable steel bars 26 are fixedly connected to the tops of the left and right side plates by bolts 27 The inside of the compaction box is provided with a push plate 28 that can move forward and backward, and the middle part of the push plate 28 is provided with a sleeve 29 that can pass through the circular hole 25...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com