Preparation method of Ag/mxene-Ti3C2 composite material with high SERS activity

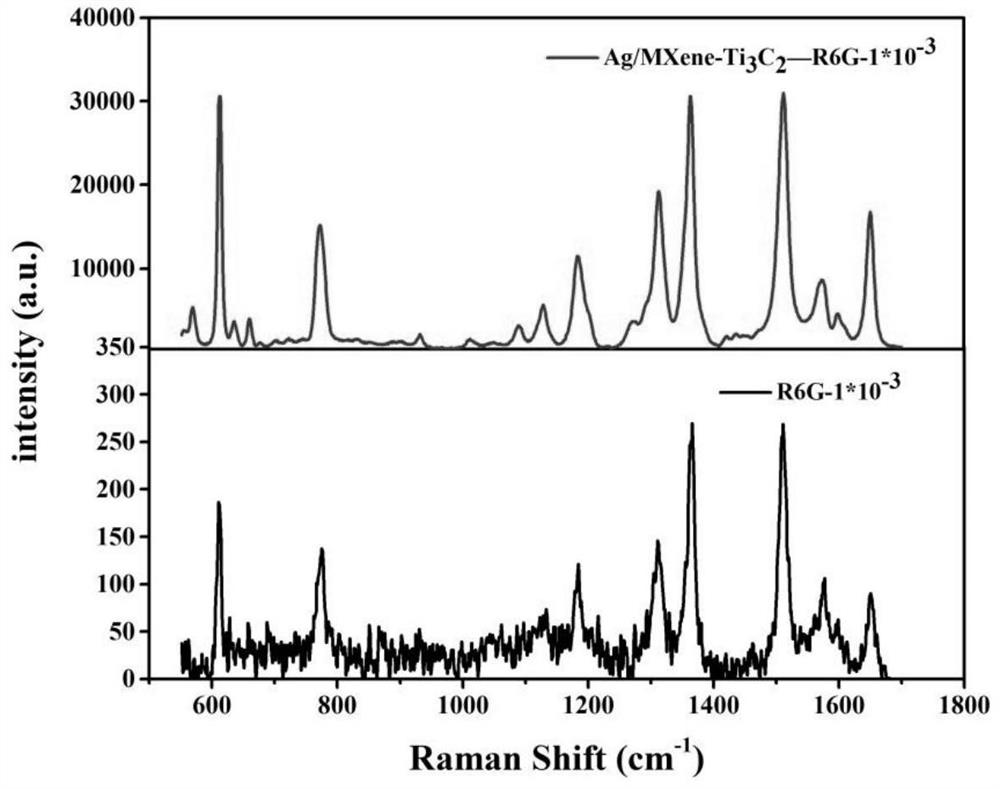

A composite material and active technology, which can be used in material excitation analysis, Raman scattering, etc., and can solve the problems of rarely reported preparation methods, poor SERS performance, and uneven distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

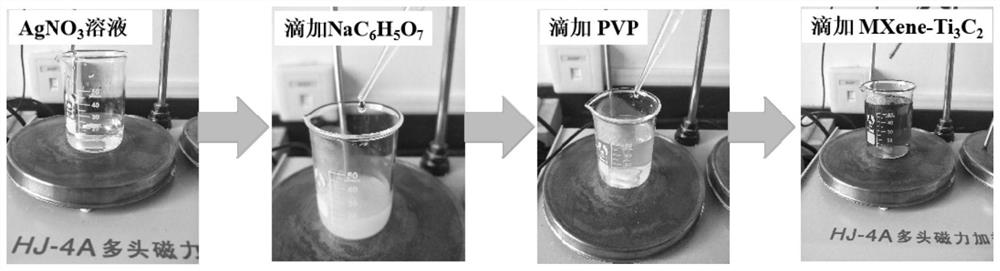

[0021] 1. The MXene-Ti 3 C 2 The solution was sonicated for 1 h in an ultrasonic machine, centrifuged at 3500 rpm for 1 h, and 5 mL of the supernatant was taken for later use;

[0022] Dissolve 95.7mg of silver nitrate in 25mL of water to make a solution for later use;

[0023] Dissolve 295mg of sodium citrate dihydrate in 25mL of water to prepare a solution for later use;

[0024] Dissolve 500mg of polyvinylpyrrolidone in 50mL of water to prepare a solution for later use.

[0025] 2. Add the sodium citrate solution dropwise to the silver nitrate solution and stir for 5 minutes, then add the polyvinylpyrrolidone solution dropwise to the mixed solution of sodium citrate and silver nitrate, and stir until the solution is evenly mixed.

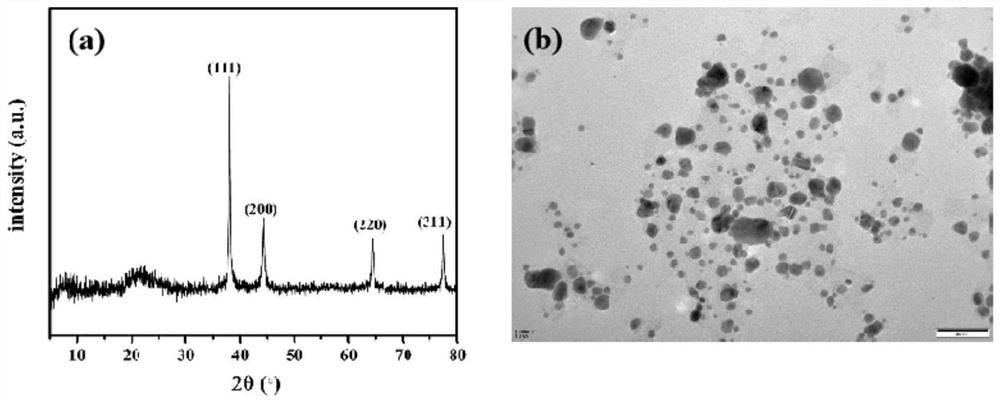

[0026] 3. The MXene-Ti 3 C 2 Add the solution dropwise to the mixed solution in step 2, stir evenly, wash and dry in a water bath at 70°C for 45 hours to obtain Ag / MXene-Ti 3 C 2 composite material. The XRD pattern of obtained sample is a...

Embodiment 2

[0028] 1. The MXene-Ti 3 C 2 The solution was sonicated for 1 h in an ultrasonic machine, centrifuged at 3500 rpm for 1 h, and 5 mL of the supernatant was taken for later use;

[0029] Dissolve 95.7mg of silver nitrate in 25mL of water to make a solution for later use;

[0030] Dissolve 295mg of sodium citrate dihydrate in 25mL of water to prepare a solution for later use;

[0031] Dissolve 300mg of polyvinylpyrrolidone in 30mL of water to prepare a solution for later use.

[0032] 2. Add the sodium citrate solution dropwise to the silver nitrate solution and stir for 5 minutes, then add the polyvinylpyrrolidone solution dropwise to the mixed solution of sodium citrate and silver nitrate, and stir until the solution is evenly mixed.

[0033] 3. Then the MXene-Ti 3 C 2 Add the solution dropwise into the mixed solution, stir evenly, wash and dry in a water bath at 70°C for 45 hours to obtain Ag / MXene-Ti 3 C 2 composite material.

Embodiment 3

[0035] 1. The MXene-Ti3 C 2 Sonicate the solution for 1h in an ultrasonicator, centrifuge at 3500rpm for 1h, take 2mL supernatant, and set aside;

[0036] Dissolve 49.7mg of silver nitrate in 25mL of water to make a solution for later use;

[0037] Dissolve 147mg of sodium citrate dihydrate in 25mL of water to prepare a solution for later use;

[0038] Dissolve 200mg of polyvinylpyrrolidone in 20mL of water to prepare a solution for later use.

[0039] 2. Add the sodium citrate solution dropwise into the silver nitrate solution and stir for 5 minutes, then add polyvinylpyrrolidone dropwise into the mixed solution of sodium citrate and silver nitrate, and stir until the solution is evenly mixed.

[0040] 3. Then the MXene-Ti 3 C 2 Add the solution dropwise into the mixed solution, stir evenly, wash and dry in a water bath at 70°C for 45 hours to obtain Ag / MXene-Ti 3 C 2 composite material. The SEM photograph of the product is as Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com