Modified preparation method of silica gel carrier

A carrier, silica gel technology, applied in catalyst carriers, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problems of expensive solvent, large solvent consumption, difficult recovery, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

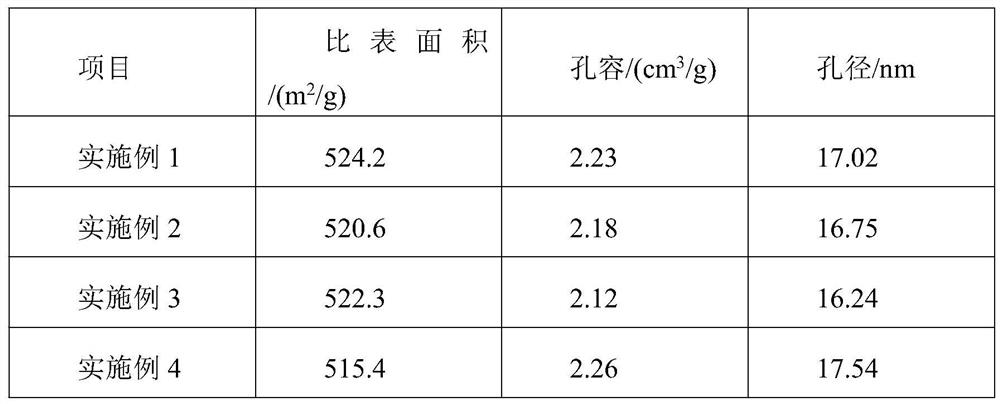

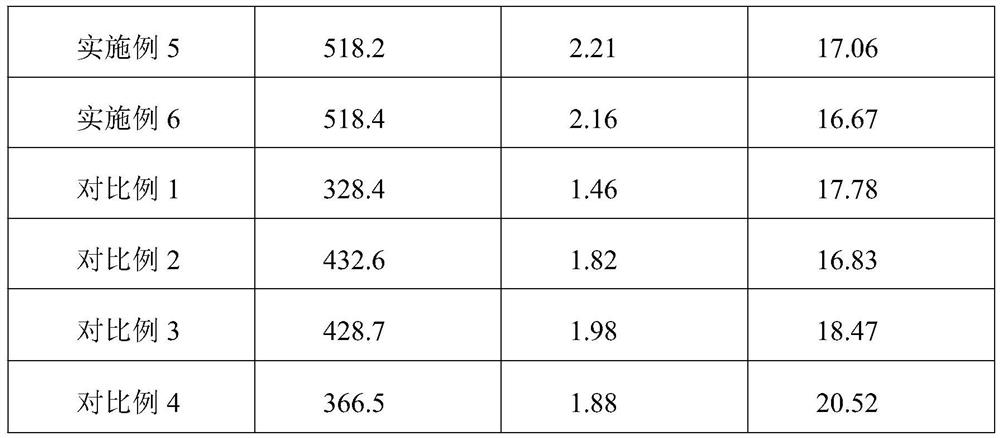

[0037]Add 20ml of sodium carbonate ethanol aqueous solution with a mass fraction of 6% into the reaction kettle (the volume ratio of ethanol to water is 1:6), turn on the stirring, raise the temperature to 50°C, and add the concentration of 1.2mol / L at a flow rate of 3ml / min Sodium silicate aqueous solution and 1.0mol / L sulfuric acid aqueous solution, when the pH value of the solution in the reactor reaches 11, stop adding the mixed aqueous solution, and react at constant temperature for 0.5h. Add 16mL of magnesium nitrate and aluminum nitrate aqueous solutions with a mass fraction of 4% at a flow rate of 8ml / min (the molar ratio of the two nitrates is 1:1), and react at a constant temperature for 1.0h after the addition is complete; add a concentration of 1.0mol at a flow rate of 6mL / min / L sulfuric acid n-butanol aqueous solution (the volume ratio of n-butanol to water is 1:15), stop adding n-butanol sulfuric acid solution when the pH value of the solution is 9, and react at ...

Embodiment 2

[0039] The preparation process is the same as in Example 1, except that 20ml of potassium carbonate ethanol aqueous solution with a mass fraction of 6% is added to the reaction kettle (the volume ratio of ethanol to water is 1:6), the stirring is turned on, and the temperature is raised to 50° C., at 3ml / min At the same time, add a potassium silicate aqueous solution with a concentration of 1.2mol / L and a sulfuric acid aqueous solution with a concentration of 1.0mol / L. When the pH value of the solution in the reactor reaches 11, stop adding the mixed aqueous solution and react at a constant temperature for 0.5h. Add 16mL of zinc nitrate and aluminum nitrate aqueous solutions with a mass fraction of 4% at a flow rate of 8ml / min (the molar ratio of the two nitrates is 1:1), and react at a constant temperature for 1.0h after the addition; Other conditions are the same as in Example 1. The test results are shown in Table 1.

Embodiment 3

[0041] The preparation process is the same as in Example 1, except that 1,3-butanediol sulfuric acid aqueous solution with a concentration of 1.0mol / L is added at a flow rate of 4mL / min, and the volume ratio of 1,3-butanediol to water is 1:10 Other conditions Same as Example 1. The test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap