Dry mulberry slag-removing shaking sieve device

A technology of mulberry and sieve plate, which is applied in the direction of sieve, solid separation, grille, etc., can solve the problems that the inclination angle of the screen cannot be adjusted, the vibration amplitude of the shaker is chaotic, and the screen hole is blocked, so as to avoid the effect of unstable vibration , Guarantee the effect of quality and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

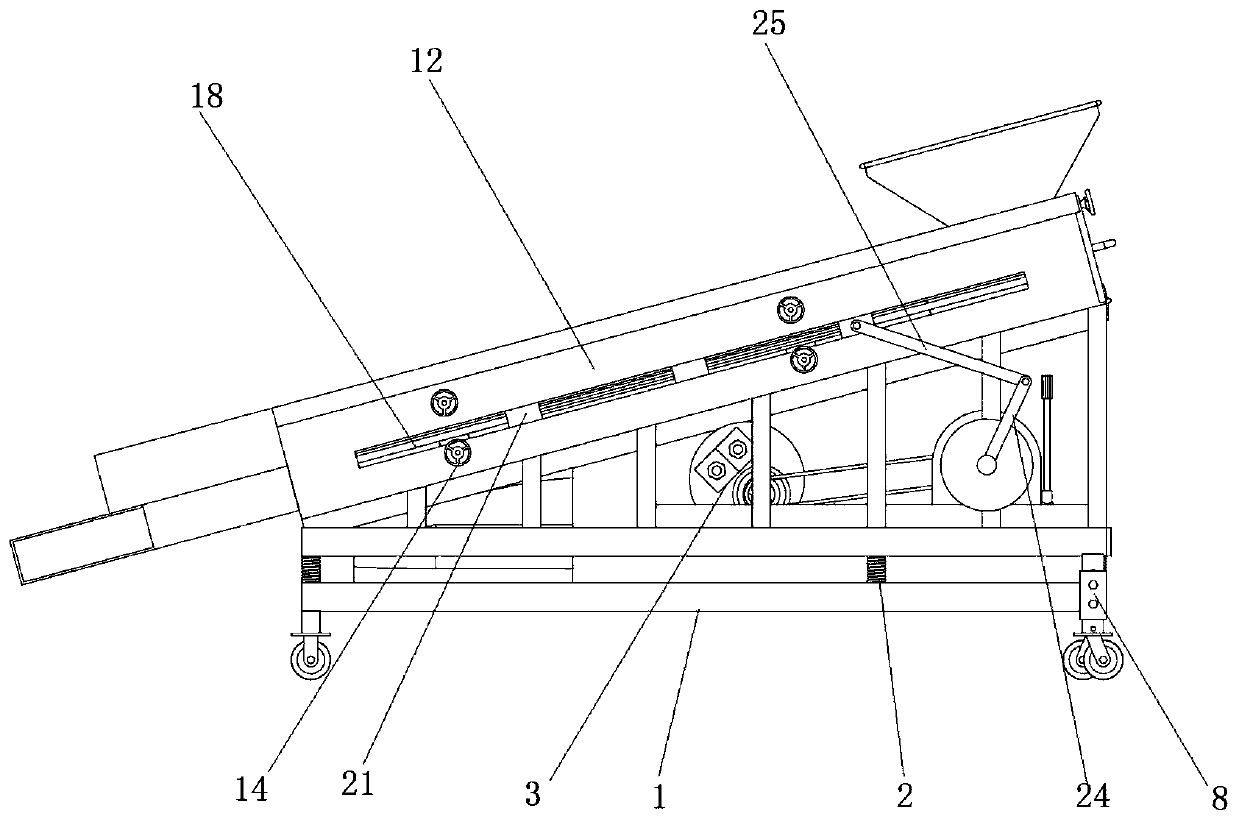

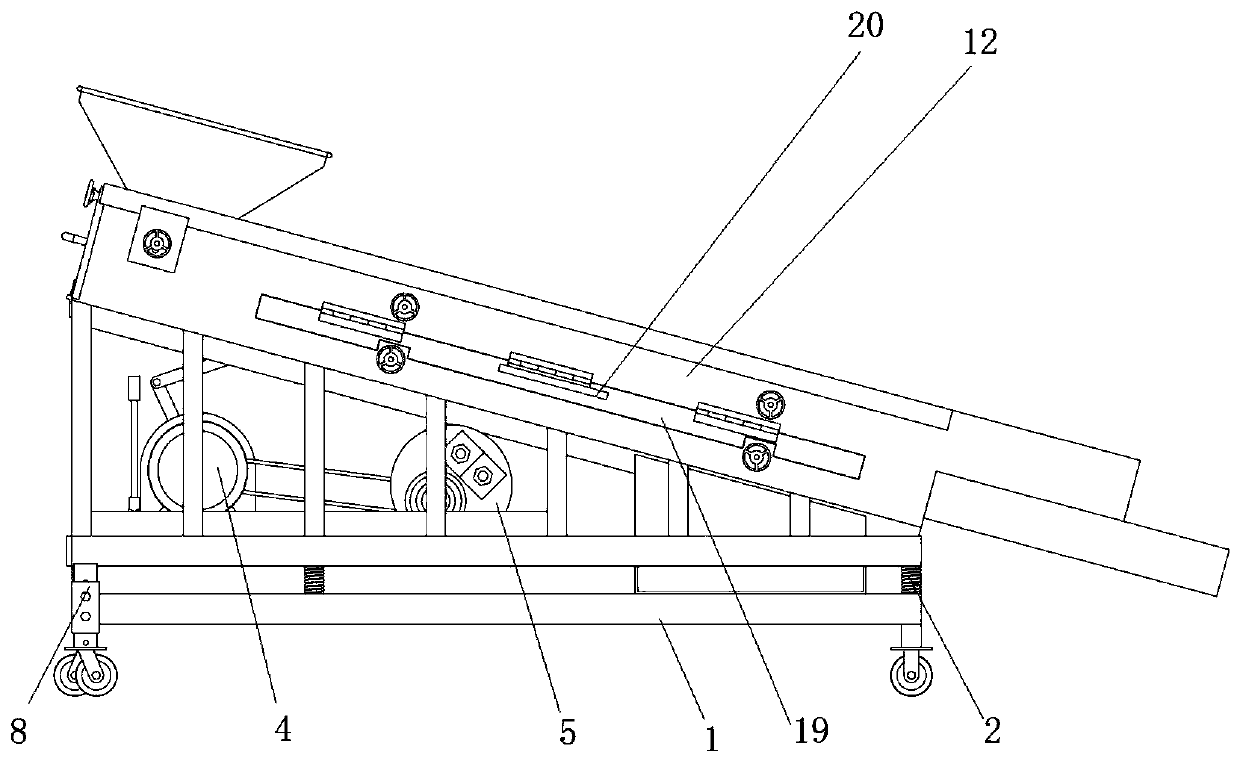

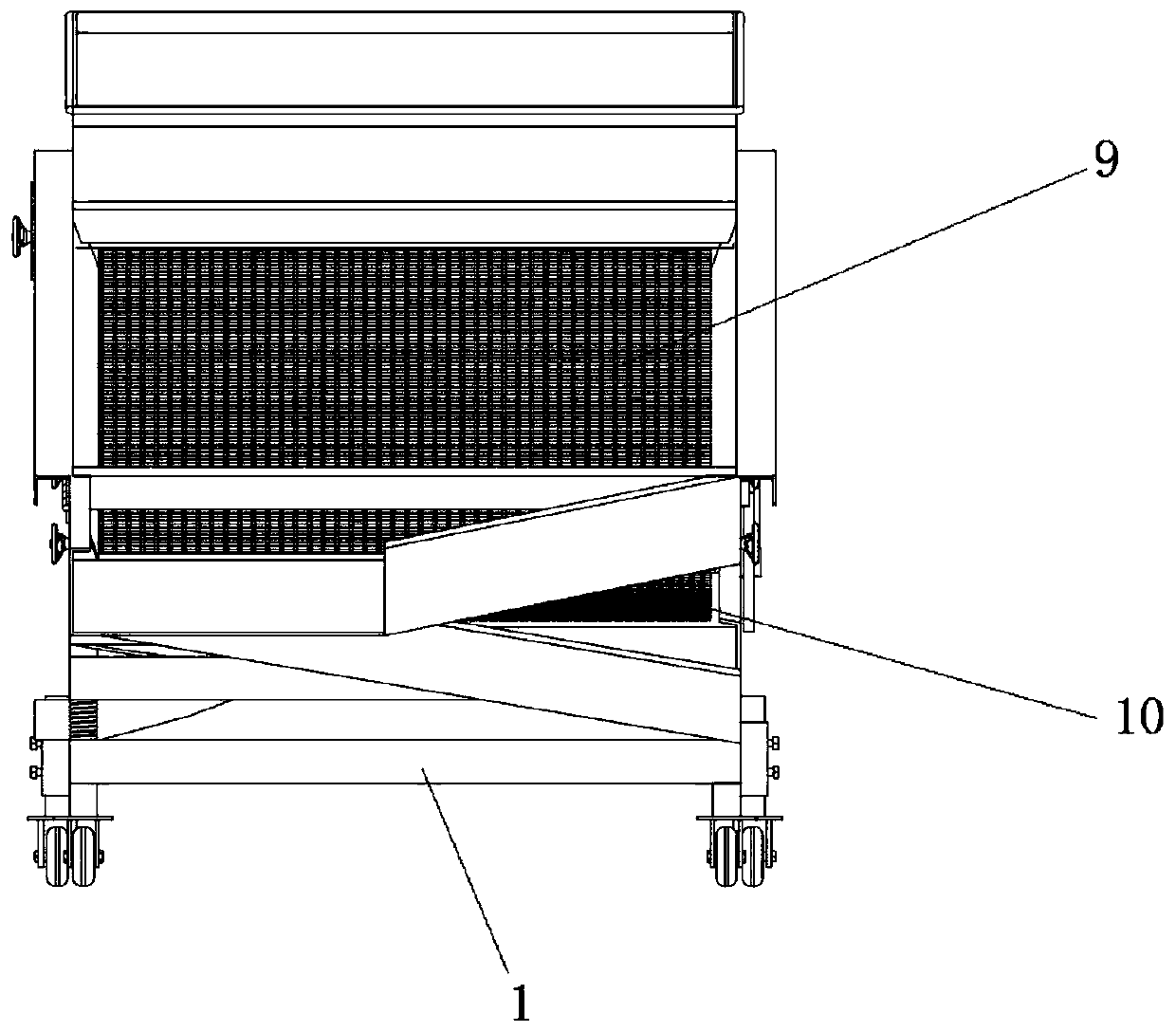

[0023] Such as Figure 1~6 As shown, a mulberry dry slag removal and shaking screen device can adjust the inclination of the screen according to the demand, and conveniently replace the screen, and add inclined baffles 11 on both sides of the screen to prevent the accumulation of dried mulberries on both sides, which can effectively The realization of the automatic and efficient cleaning of the two-layer sieve; specifically, the present invention is realized in this way: a mulberry dry slag removal and shaking sieve device includes a support 1 and a sieve plate structure, and the bottom of the sieve plate is inclined by several spring parts 2 Installed on the support 1, a vibrating screen mechanism 3 is installed at the bottom of the sieve plate. The vibrating screen mechanism 3 includes a motor 4 and an oval vibrating piece 5. The motor 4 is connected to the rotating shaft 7 of the vibrating piece 5 through a transmission belt 6. The rotating shaft 7 Installed on the non-cent...

Embodiment 2

[0026] On the basis of Example 1, such as Figure 1 to Figure 7As shown, one of the side plates 12 is provided with a first chute 18 along the length direction of the side plate 12, and the other side plate 12 is provided with a hinged opening and closing side door 19 along the length direction of the side plate 12. Offer the second chute 20 that is matched with the first chute 18 and parallel, the position of the first chute 18 and the second chute 20 is provided between the first screen cloth 9 and the second screen cloth 10, the first Three sliders 21 are installed in the chute 18, and the three sliders 21 are evenly and equidistantly placed in the first chute 18 and connected to each other by connecting rods 22, and the three sliders 21 are provided with transversely extending bars. 23. The other end of the cross bar 23 is placed in the second chute 20, the endmost slider 21 is rotatably connected to the end of the first rotating rod 24, and the end of the first rotating r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com