Casting technology of buffer box body

A buffer box and process technology, which is applied in the field of technology, can solve the problems of not very ideal fixing effect of the formwork, poor heat transfer speed, and decreased impact resistance of the box, so as to achieve a compact and compact box. The effect of enrichment and improvement of product pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, the present invention will be further described by preferred embodiment:

[0026] Such as figure 1 As shown, the casting process of the buffer box includes the following steps:

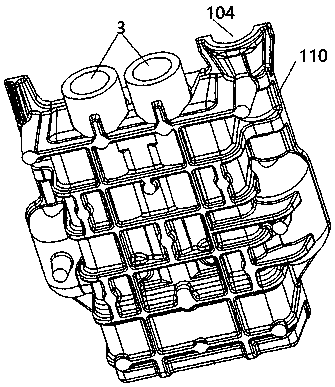

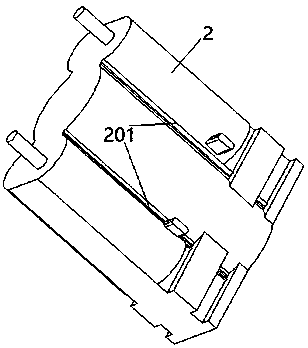

[0027] (a) First, use zircon sand coated sand as the material to make the casting mold for the buffer box. The casting mold includes a mold shell and an inner core 2. The mold shell has a cavity 101, and casting pipes 102 are respectively provided on both sides of the cavity 101. And the overflow pipe 103, the casting pipe 102 and the overflow pipe 103 are all connected with the cavity 101, and the top of the cavity 101 is provided with a liquid replenishment port 3, and the lower port 350 of the liquid replenishment port 3 is connected with the cavity 101, and the inner core 2 is provided with There are vertical grooves 201, and the vertical grooves 201 are used to shape the reinforcing ribs of the side walls of the box after the mold cavity is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com