Oil tank liquid level control exhaust valve with low dynamic leakage amount

A technology of liquid level control and leakage, which is applied in the direction of valves, valve details, valve devices, etc. for ventilation, which can solve the problems of large dynamic leakage, complex anti-leakage structure, low dynamic leakage, etc., and reduce the vacuum degree , solve the dynamic fuel leakage, reduce the effect of pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

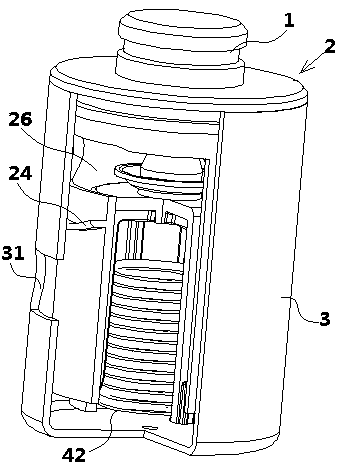

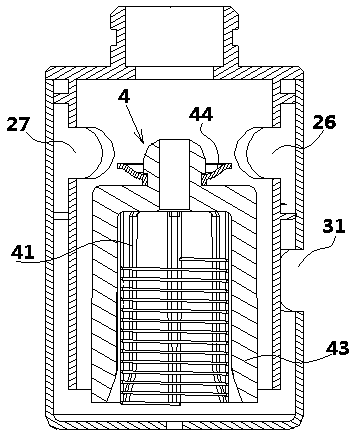

[0035] Such as figure 1 , figure 2 , image 3 with Figure 4As shown, a fuel tank liquid level control exhaust valve with low dynamic leakage in this embodiment includes a valve body 2, a housing 3 sleeved on the outside of the valve body 2 and a float located in the inner cavity of the valve body 2 Assembly 4, wherein, the float assembly 4 of the present embodiment includes a spring support 41, a spring 42, a float 43 and a sealing plate 44, the spring support 41 includes a plurality of supports, and the plurality of supports surround a cylindrical support, and the cylindrical support A spring 42 is set on the outside of the bracket, and a float 43 is set on the outside of the spring 42. The lower end of the float 43 is a trumpet-shaped opening, and a sealing sheet 44 is provided on its upper end. The inside surface of the inner surface is provided with a clamping bar engaged with the above-mentioned clamping groove, and the matching setting of the clamping groove and the...

Embodiment 2

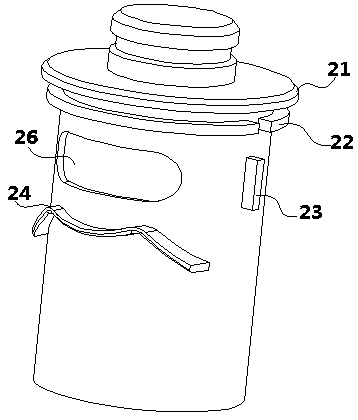

[0039] A fuel tank liquid level control exhaust valve with low dynamic leakage in this embodiment has the same basic structure as that in Embodiment 1, except that the exhaust port I26 in this embodiment is located on the front of the valve body 2, and the valve The back of the body 2 is also provided with an exhaust port II 27. In this embodiment, the exhaust port II 27 is provided on the back of the valve body 2, so that the oil and gas in the fuel tank can be discharged through more gas channels, such as Figure 5 As shown, the oil and gas can be discharged through the air inlet 31, the exhaust port I26 and then through the air outlet on the valve body 2 (that is, the A gas channel), or the oil and gas can be discharged through the air inlet 31, the exhaust port II27 and then through the valve body 2 It should be emphasized that this implementation effectively reduces the vacuum degree near the sealing sheet 44 by reasonably setting the positional relationship between the A ...

Embodiment 3

[0041] A fuel tank liquid level control exhaust valve with low dynamic leakage in this embodiment has the same basic structure as that in Embodiment 2, the difference is that in this embodiment, it is below the exhaust port II 27 and on the side of the valve body 2 The limit block II25 is arranged on the top, and the limit block II25 is arranged along the circumferential direction of the side of the valve body 2. The limit block I23 is arranged on the side of the valve body 2 between the exhaust port I26 and the exhaust port II27, and the limit block I23 is arranged along the valve body. The axial arrangement of the body 2, in this embodiment, by setting the limit block I23 and the limit block II25 on the side of the valve body 2, the position eccentricity of the valve body 2 and the shell 3 during assembly or welding is effectively avoided, ensuring that the valve The coaxiality of body 2 and shell 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com