Lens module detection method and system

A lens module and detection method technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of inaccurate detection results, high quality inspection costs, and slow detection speed, so as to improve user experience and effect , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 is a method for detecting a lens module.

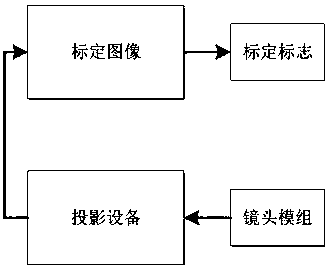

[0029] Such as figure 1 , is a schematic diagram of a lens module detection method, wherein the projection device includes a lens module, and the calibration image includes a calibration mark. The method of detecting the lens module by calibrating the image is realized through the following steps:

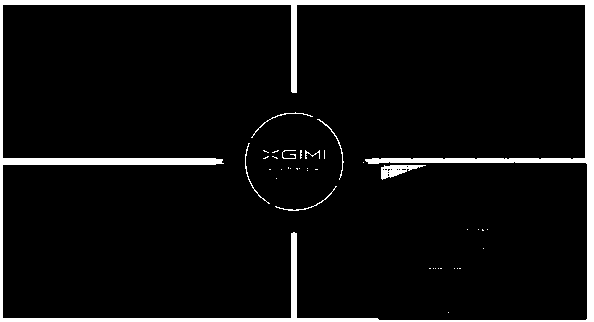

[0030] The projection device is placed on the detection platform during pre-delivery inspection. The detection platform includes a base for placing the projection device and a fixedly installed calibration image. The positional relationship between the calibration image and the base of the detection platform has been fixed, so that the projection device The lens module is facing the calibration image;

[0031] The calibration image is an image used for testing, and there is a logo graphic for calibration in the center of the calibration image. In one embodiment, the logo graphic is a circular logo, and it can also be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com