Photonic crystal super-resolution imaging device with variable period grating

A super-resolution imaging and photonic crystal technology, applied in optical components, instruments, optics, etc., can solve the problems of photonic crystals, such as the absence of simultaneously negative permittivity and permeability, and the controversy over the super-resolution imaging mechanism. The effect of breaking through the diffraction limit and improving imaging resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

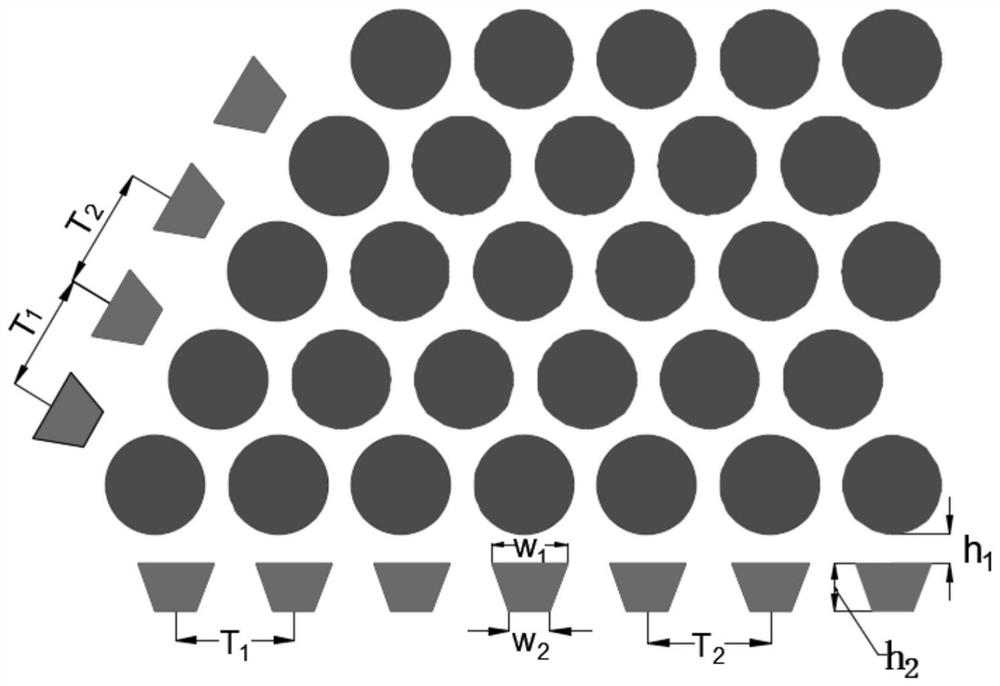

[0017] First, the parameters of the photonic crystal are designed so that the equivalent refractive index is -1. The background material is a silicon medium with a refractive index of n=3.45, and air columns are arranged periodically in the silicon medium in a hexagonal lattice. Air column radius r = 193.5nm, lattice constant a = 482nm.

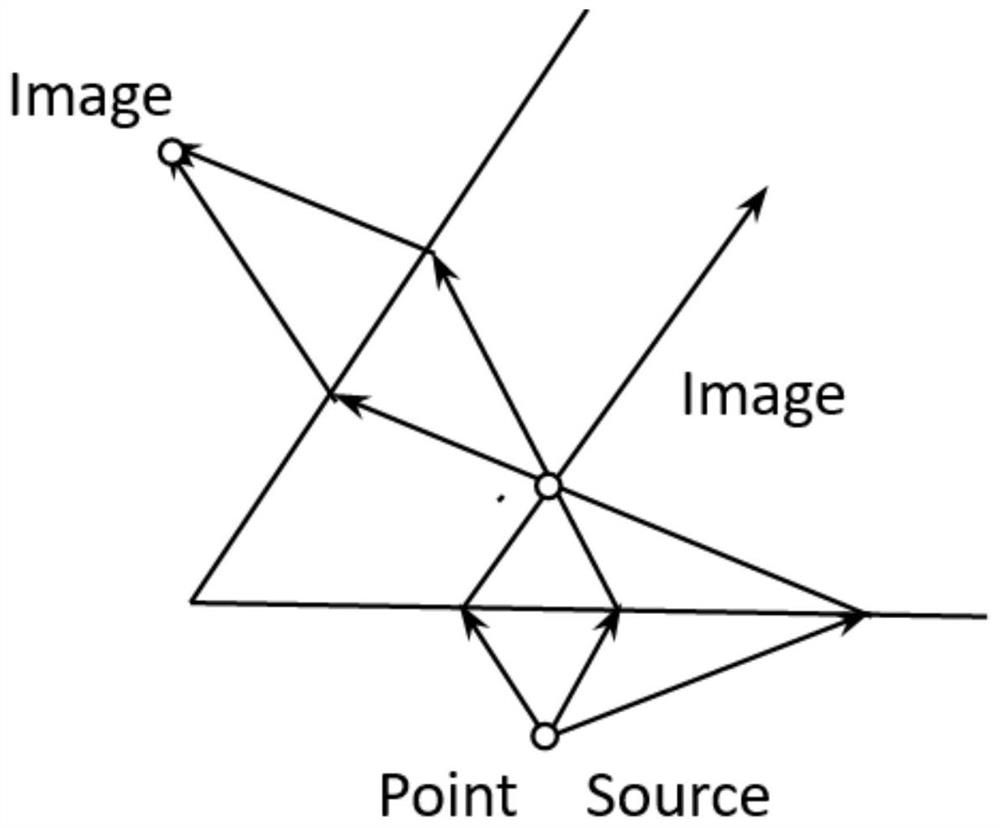

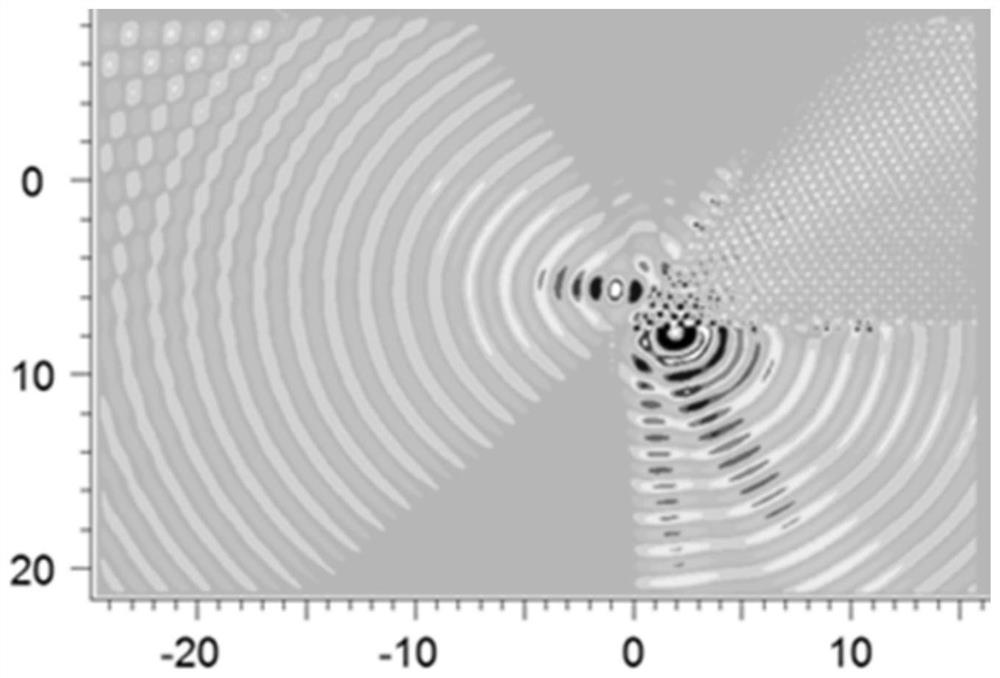

[0018] like figure 1 The schematic diagram of the photonic crystal imaging process is shown. The point source (Point Source) is placed in the near-field range below the photonic crystal. After negative refraction, a virtual image point (Image) is formed inside the photonic crystal, and the internal image point is negatively refracted. It acts on the external image space of the photonic crystal for imaging. Because the photonic crystal has an equivalent refractive index of -1, it can amplify the evanescent wave of the light source and achieve imaging that breaks through the diffraction limit. However, the surface structure of the photonic c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com