A method for confirming a CFD drag model of a liquid-solid fluidized bed

A fluidized bed and drag technology, applied in the field of fluidized bed multiphase flow CFD simulation, can solve the problems of time-consuming and computing resources, omission of the best model, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

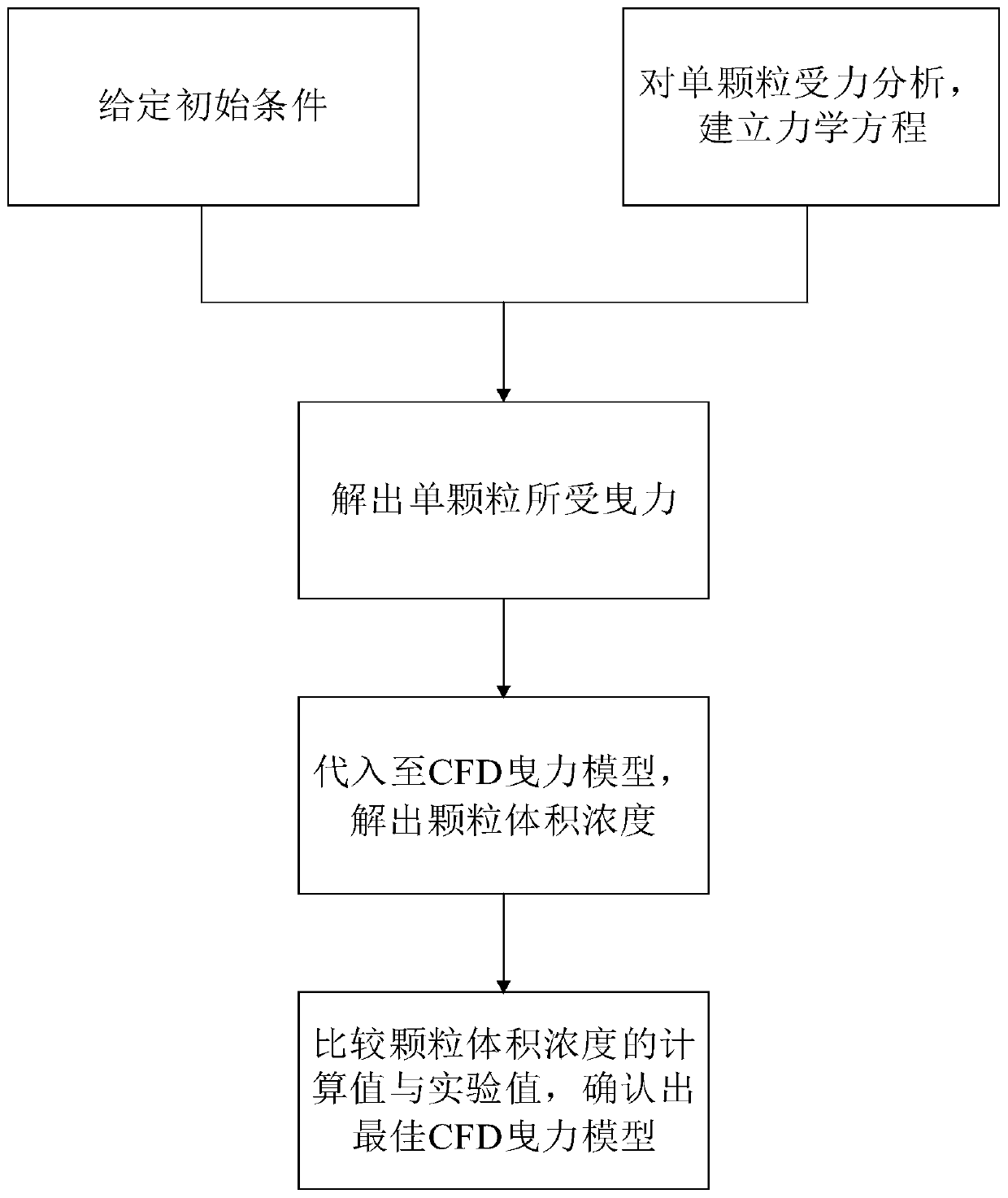

Image

Examples

Embodiment 1

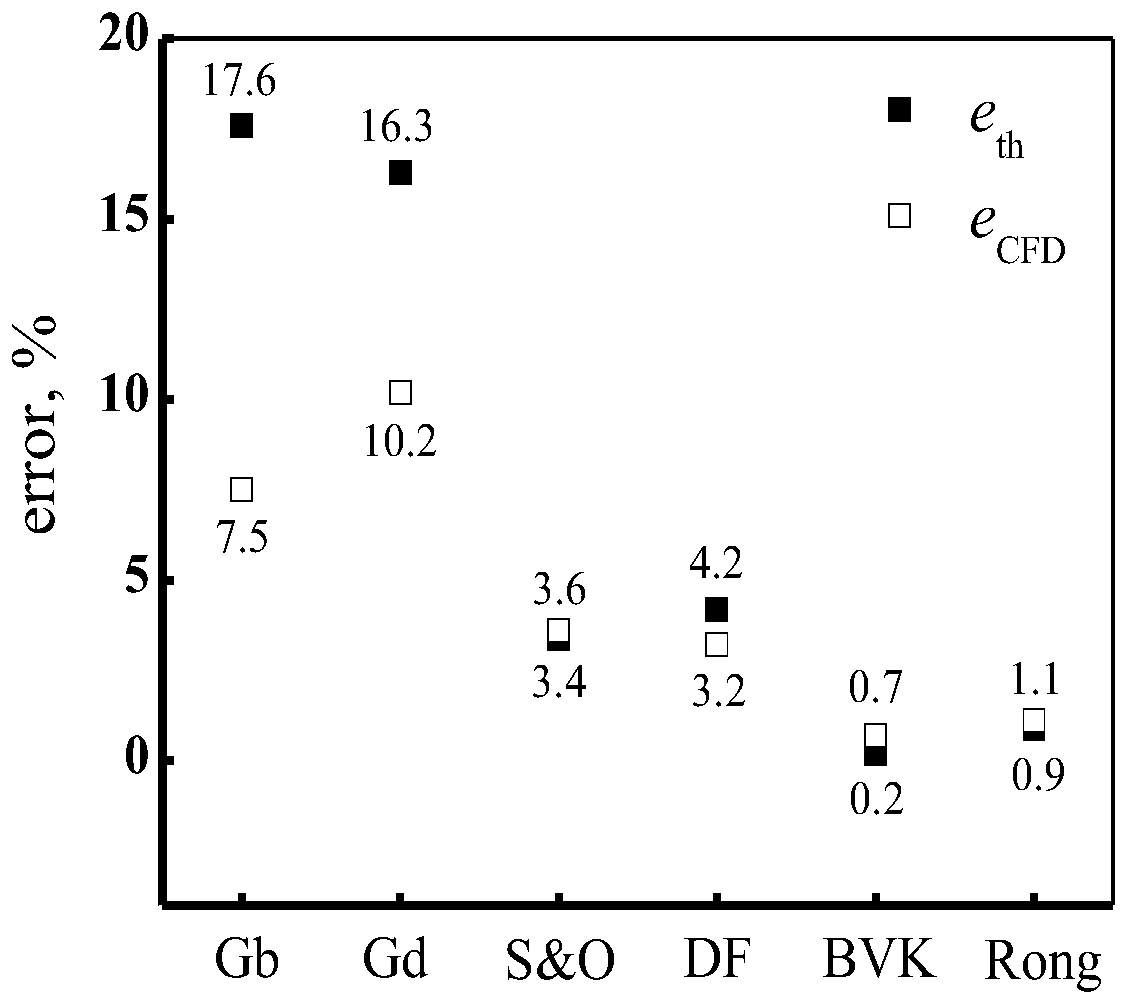

[0085] Step 1. Given initial conditions:

[0086] Physical parameters: particle diameter d p =0.003m, particle density ρ p =2500kg / m 3 , fluid density ρ f = 1000kg / m 3 , fluid dynamic viscosity μ = 0.001Pa s; operating conditions: superficial velocity u 0 =0.07m / s; and at superficial velocity u 0 =0.07m / s, the experimentally measured particle volume concentration φ=0.44.

[0087] Step 2. Analyze the force on a single particle and establish a mechanical equation: Generally, the bed of a liquid-solid fluidized bed is approximated as a liquid-solid suspension. The liquid-solid suspension has the following two characteristics: the particles in the suspension are in a state of force balance ; The interaction between particles can be ignored; therefore, it can be considered that a single particle in a liquid-solid fluidized bed is only affected by gravity G, buoyancy F b and the drag force F exerted by the fluid d , and its equilibrium equation is:

[0088] G=F b +F d (1...

Embodiment 2

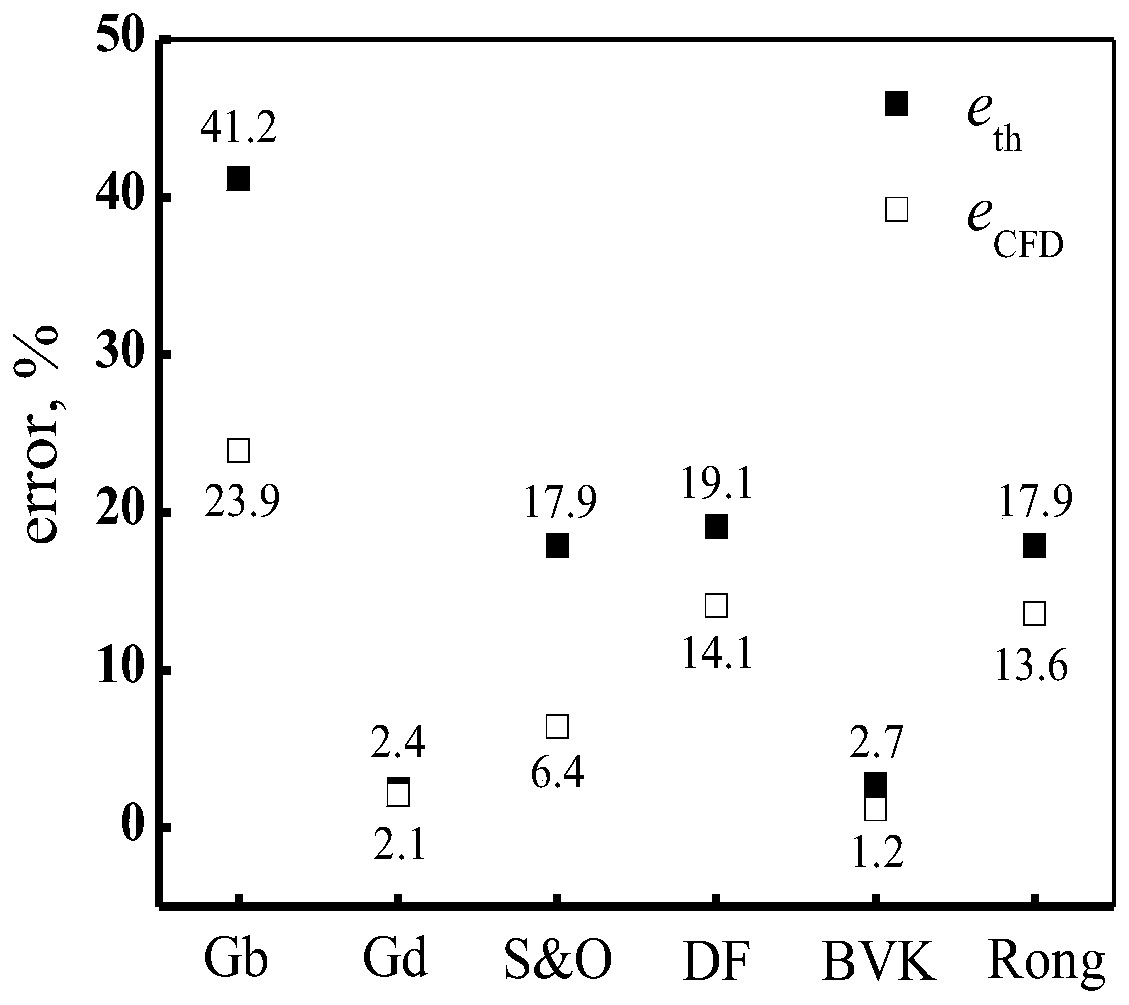

[0141] Step 1. Given initial conditions:

[0142] Physical parameters: particle diameter d p =1.13mm, particle density ρ p =2540kg / m 3 , fluid density ρ f =999.5kg / m 3 , fluid dynamic viscosity μ = 0.00124Pa s; operating conditions: superficial velocity u 0 =0.0381m / s; and at superficial velocity u 0 =0.0381m / s, the experimentally measured particle volume concentration φ=0.342.

[0143] The implementation process of steps 2-4 is the same as that of case 1, and will not be repeated here.

[0144] The following only shows the relevant calculation results of the steps: As can be seen from the table and the figure, observe e th , the relative error of the BVK drag model is the smallest, followed by the Gidaspow drag model; and the observed e CFD , then the relative error of the Gidaspow drag model is the smallest, followed by the BVK drag model; therefore, the two methods get the same conclusion, that is, the recommended drag model suitable for this system is the Gidaspow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com