A Bistable Contactor Based on Pulse Trigger

A technology of pulse triggering and contactors, applied in the direction of relays, electromagnetic relays, detailed information of electromagnetic relays, etc., can solve the problems of relay damage, failure to guarantee the 90-degree ratchet, collision, etc., and achieve the effects of cost reduction, compact structure, and sensitive action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

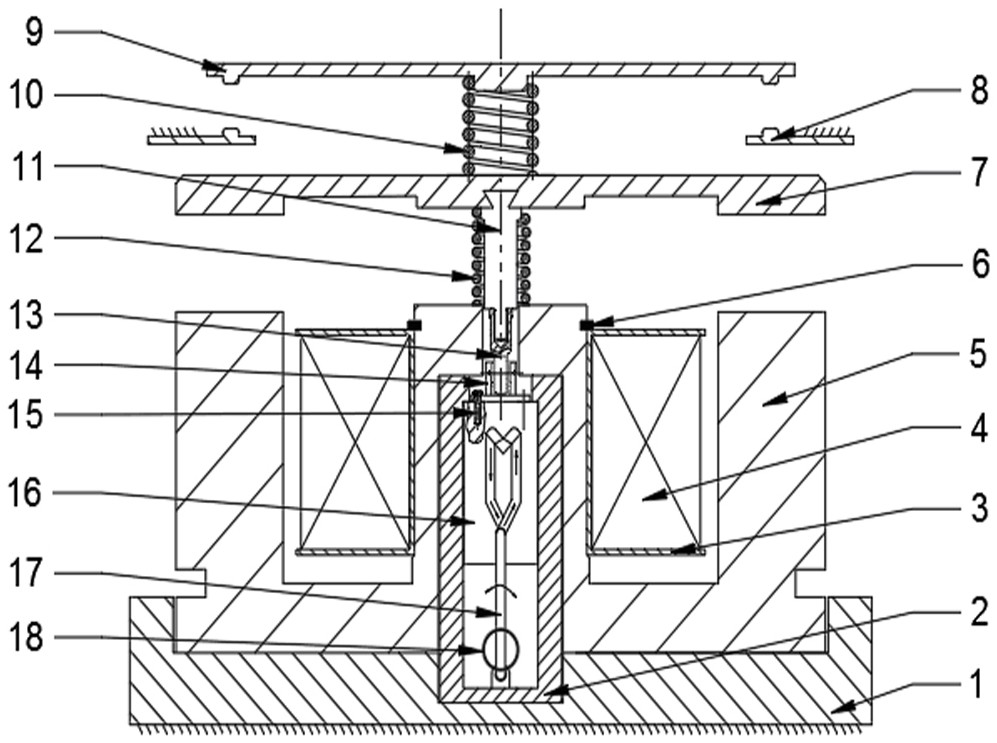

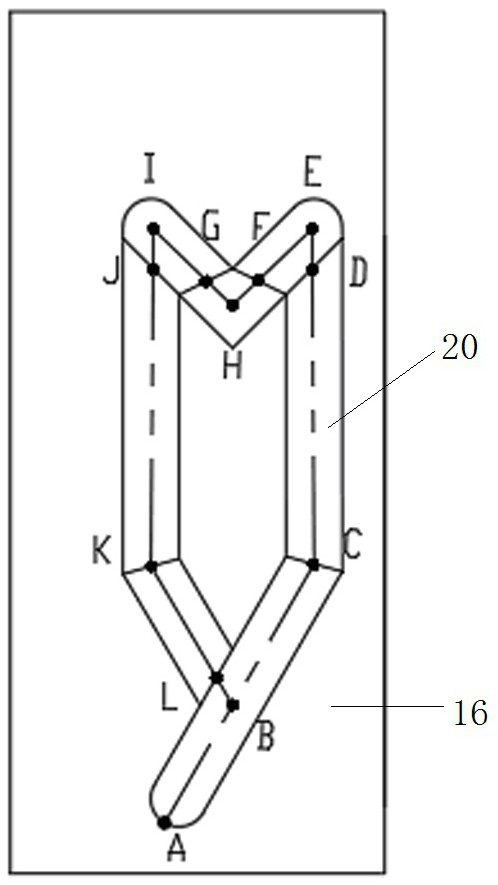

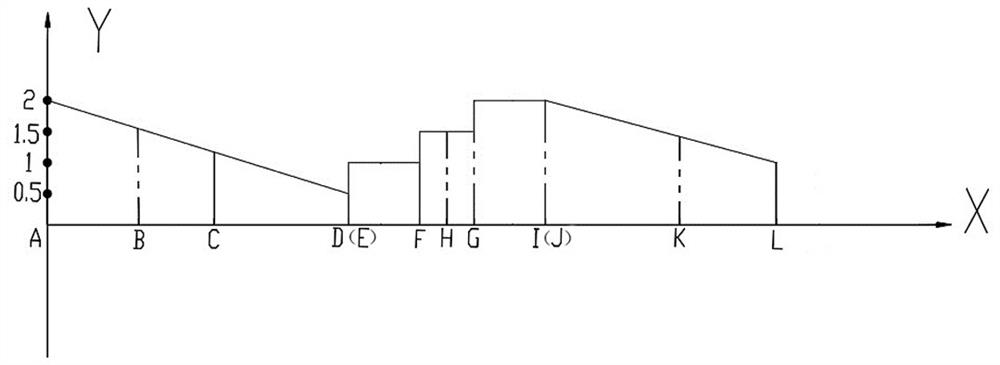

[0027] Such as Figure 1~10 As shown, a bistable contactor based on pulse triggering includes a base 1 and a static iron core 5 installed on the upper side of the base 1. A coil 4 is placed on the static iron core 5, and a receiving device is arranged above the static iron core 5. The moving iron core 7 that can move downward after being magnetically adsorbed, the upper side of the moving iron core 7 is provided with a static contact 8, and the upper side of the static contact 8 is provided with a moving contact 9 connected with the moving iron core; the inside of the static iron core 5 is provided There is a cavity, the cavity of the static iron core 5 is provided with a slide block 16 connected with the moving iron core 7 through a push rod 11, the slide block 16 is provided with a self-locking channel 20 forming a closed-loop structure, the cavity of the static iron core 5 The cavity is provided with a lock bar 17 that can lock its state when the contactor is opened and clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com