Semi-rigid composite polyester net cage and assembling process thereof

A composite polyester and semi-rigid technology, applied in the field of marine engineering, can solve the problems of escaped fish from the net bag, damage to the net cage, tearing of the fishing net, etc., and achieve the effect of improving strength, reasonable design, and avoiding loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

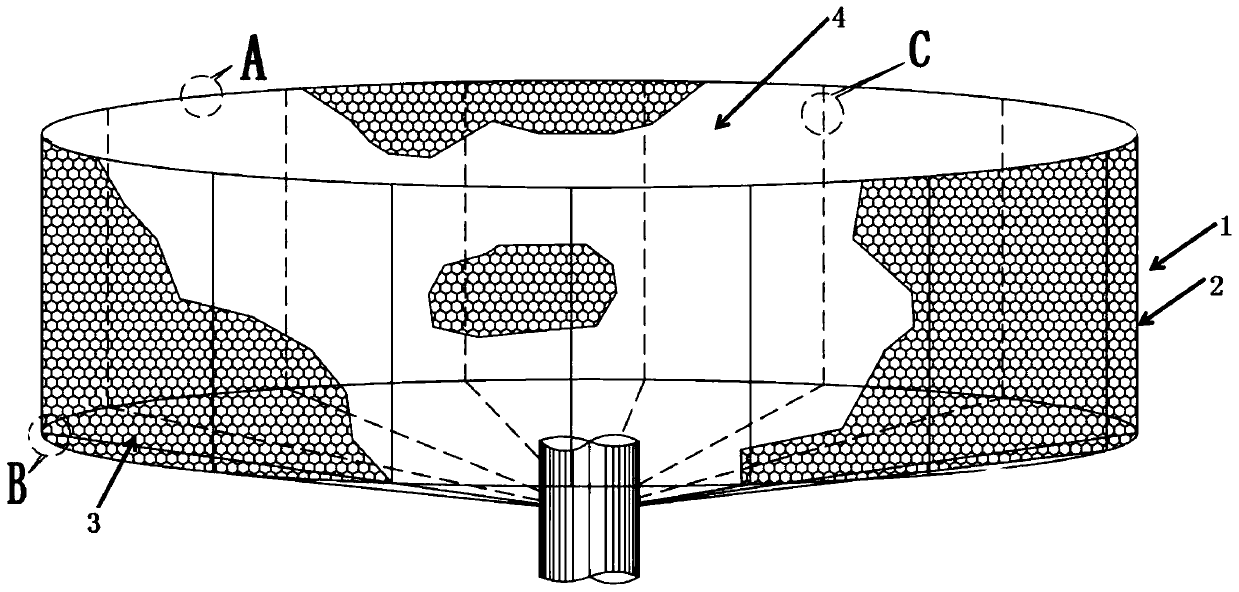

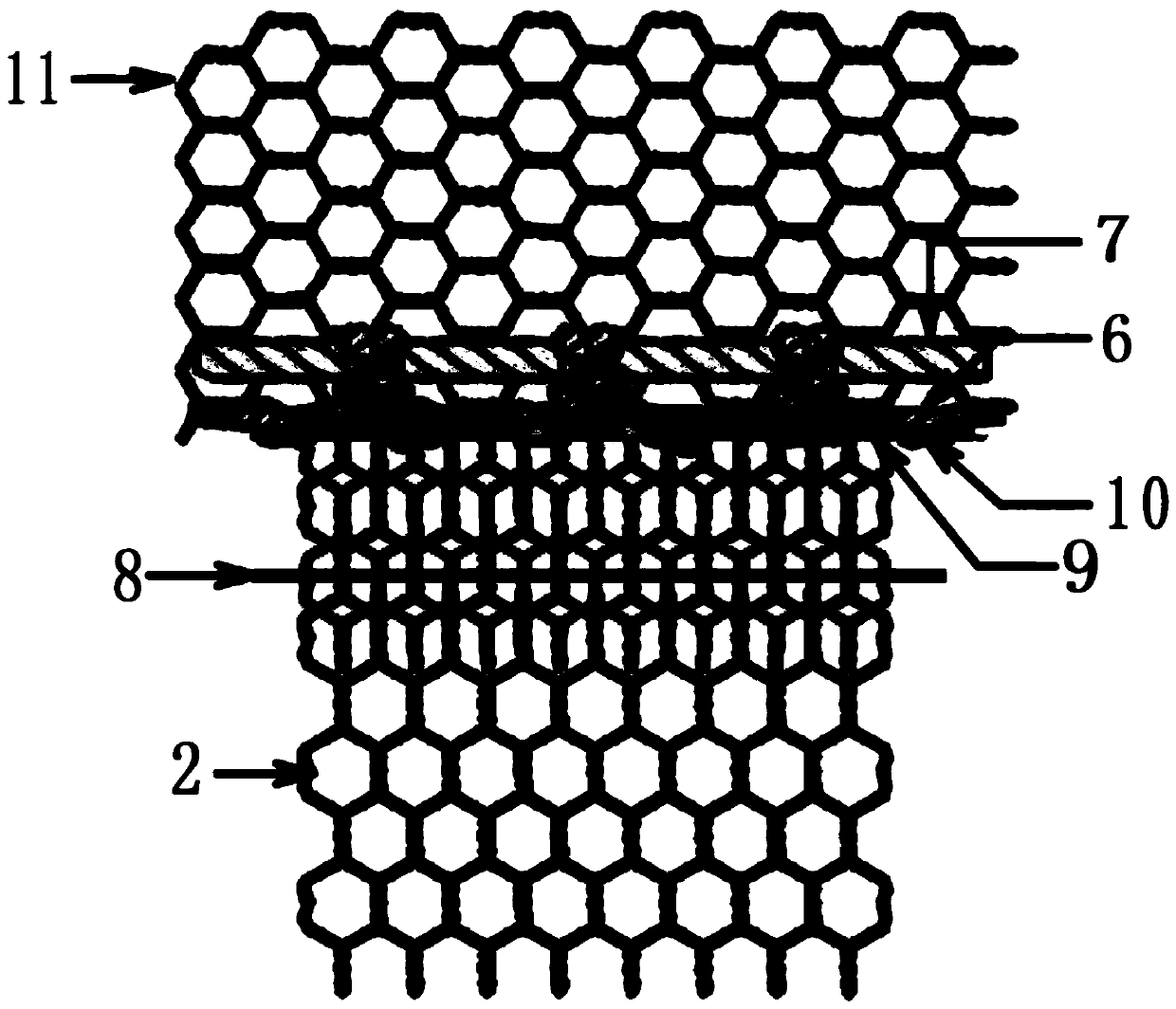

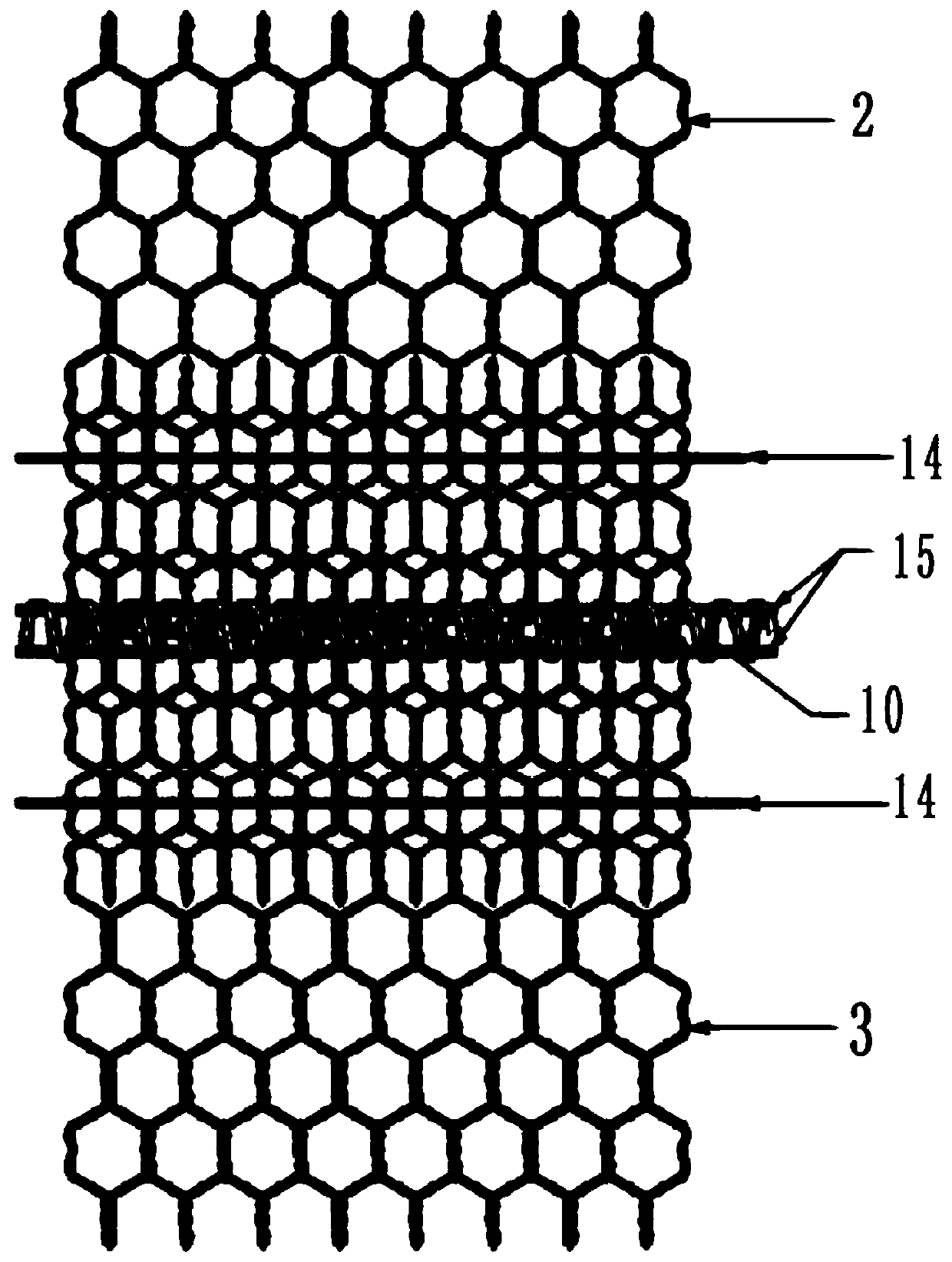

[0026] A semi-rigid composite polyester cage, comprising a net bag 1, the net bag 1 is composed of a side net 2 and a bottom net 3, wherein the side net 2 is formed by splicing several mesh sheets 4, and the mesh sheet 4 is formed by several The netting 5 is spliced to form, and the netting 5 is woven into a net by polyester threads. In addition, the top of the side net 2 is provided with a transitional net rope 6 and a side rope 7, and the transitional net rope 6 is evenly spaced on the side rope 7. Knotting, the top of the side net 2 is turned over and the polyester thread 8 is passed through the mesh to fix the fold in turn, and the side net 2 is folded inside to be provided with a connecting weft 9, and the connecting weft 9 is wound with a rope 10 to connect the transition rope 6.

[0027] The top of the side net 2 is also provided with a skip net 11, and the jump net 11 is fixed on the transition rope 6 together with the connecting weft 9 through the rope 10.

[0028]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com