Popping ball for cigarette with appearance with waterproof wax layer and preparation method thereof

A waxy layer and blasting bead technology, which is applied in applications, tobacco, and e-liquid filter elements, can solve problems such as uneven release of flavors, reduced brittleness, and increased crushing pressure of exploding beads for cigarettes, so as to improve experience comfort, Avoid the effect of absorbing water and becoming tougher and improving brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

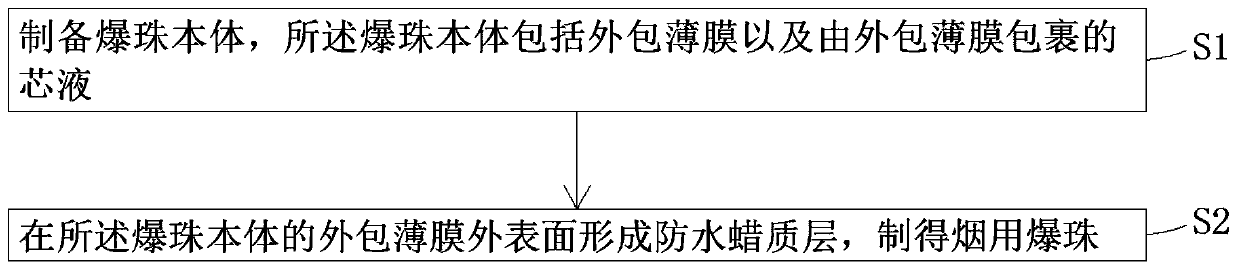

[0053] see figure 1 , based on the above-mentioned popping beads for cigarettes, the present invention provides a method for preparing the above-mentioned popping beads for cigarettes, comprising the following steps:

[0054] Step 1, prepare the popping bead body, the popping bead body includes an outsourcing film and a core liquid wrapped by the outsourcing film;

[0055] Step 2, forming a waterproof waxy layer on the outer surface of the wrapping film of the popping bead body to obtain the popping bead for cigarettes.

[0056] Specifically, the material of the outer wrapping film includes glue, and the glue includes at least one of gelatin, konjac gum, xanthan gum, carrageenan, guar gum, pectin, starch, and locust bean gum.

[0057] Optionally, the material of the outer coating film also includes nanoparticles uniformly dispersed in the adhesive material.

[0058] Specifically, the mass ratio of the glue material to the nanoparticles in the outsourcing film is 20-30:0.1-3,...

Embodiment 1

[0111] This embodiment 1 provides a kind of preparation method of quick-fried beads for cigarettes, comprising the steps of:

[0112] Step 1, prepare the popping bead body, the popping bead body includes an outsourcing film and a core liquid wrapped by the outsourcing film;

[0113] Step 2, forming a waterproof waxy layer on the outer surface of the wrapping film of the popping bead body to obtain the popping bead for cigarettes.

[0114] Said step 1 includes:

[0115] Step 11, preparing the stock solution of the outsourcing film and the core solution; wherein, the step of preparing the stock solution of the outsourcing film includes:

[0116] Step 111, providing an adhesive raw material system, the adhesive raw material system including adhesive and water;

[0117] Step 112, after adding all the components in the adhesive raw material system into the container, heat the container to melt the adhesive material in the adhesive raw material system to form an outsourcing film s...

Embodiment 2

[0132] This embodiment 2 provides a method for preparing popcorn for cigarettes. Compared with the method for preparing popcorn for cigarettes in the above-mentioned embodiment 1, the difference is that the step 112 also includes: Add nanoparticles and mix well;

[0133] After adding nanoparticles to the stock solution of the outsourcing film, the mass ratio of glue, water and nanoparticles in the stock solution of the outsourcing film is 25:75:0.5;

[0134] The nanoparticles are spherical polyethylene particles; the diameter of the polyethylene particles is 80nm.

[0135] The crushing pressure of the popping beads for cigarettes prepared by the preparation method of the popping beads for cigarettes in this embodiment 2 is 2.37kg in a dry state; after being placed in an environment with a relative humidity of 95% for 48 hours, The crushing pressure is 2.39kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com