Method for fast dyeing on European oak floor by utilizing inorganic compounds

An inorganic compound and rapid dyeing technology, which is applied in the field of wood dyeing and finishing, can solve the problems of cumbersome steps, unfriendly chemical treatment steps, and equipment requirements, etc., and achieve the effects of simple steps, improved dimensional stability, and reduced warpage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

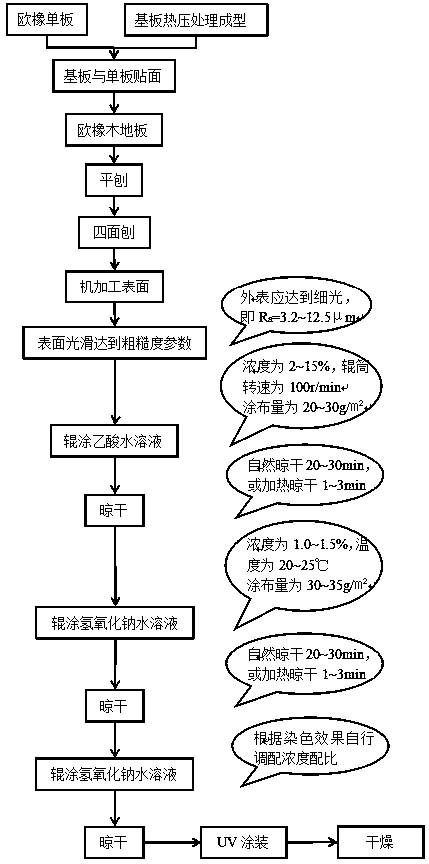

[0046] A kind of method that utilizes inorganic compound to European oak floor fast dyeing, its feature comprises the following steps:

[0047] (1) Substrate and European rubber veneer veneer

[0048] (2) Machining of European Oak Flooring

[0049] (3) Roller coating with acetic acid aqueous solution;

[0050] (4) Roll coating sodium hydroxide aqueous solution;

[0051] (5) UV coating.

[0052] The step (1) veneering the substrate and the European oak veneer: veneering the European oak veneer and the hot-pressed substrate to obtain the European oak flooring material.

[0053]The step (2) European oak floor machining treatment: the length and width are cut according to the requirements, and the positioning four-side planing, fixed-length four-side planing, double-end fine cutting, bottom surface sanding and surface sanding are carried out respectively, so that the surface of the floor can reach Fine light, contour arithmetic mean deviation Ra=5.5μm; the floor is cut and sha...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap