Titanium alloy sheet heat stretching forming tooling and forming method

A hot-stretching, titanium alloy technology, applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult control of quality stability, difficult control of thinning rate, high local thinning rate, etc., to achieve shortened development The effect of improving the cycle and forming accuracy and simplifying the control link

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

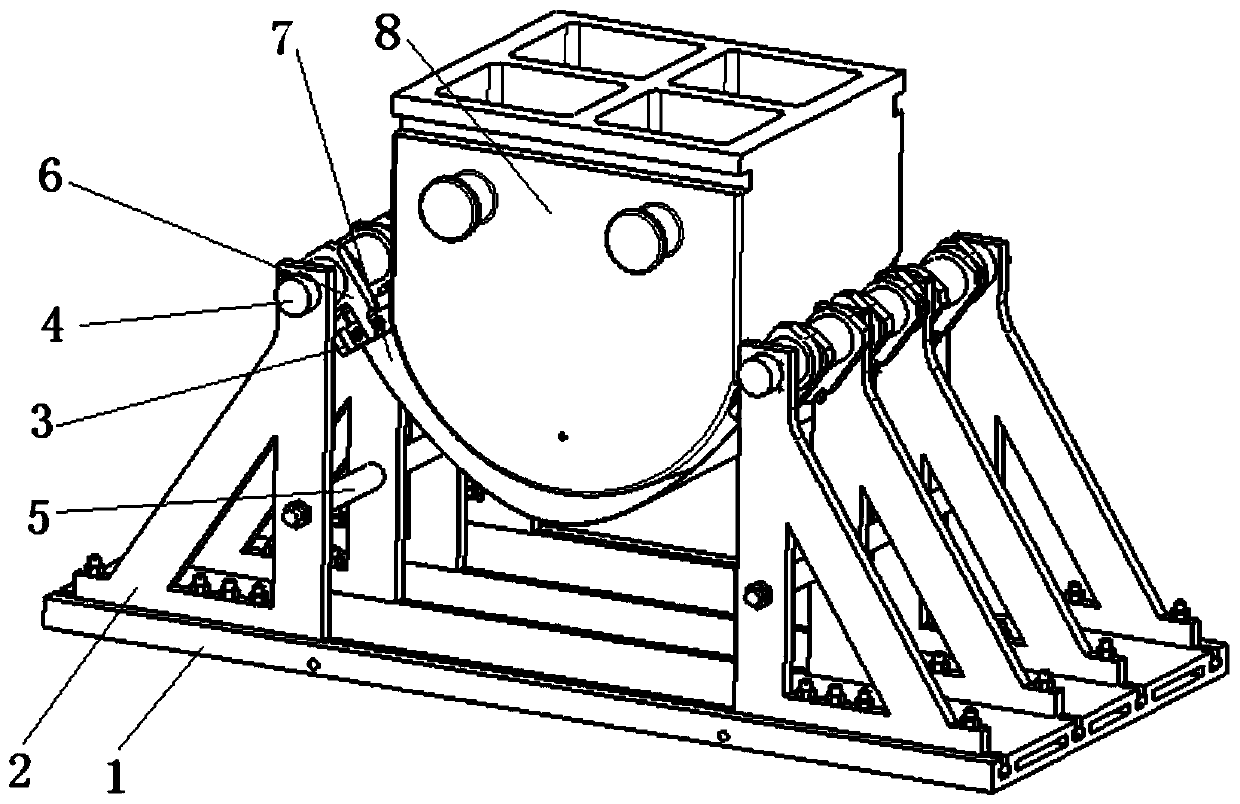

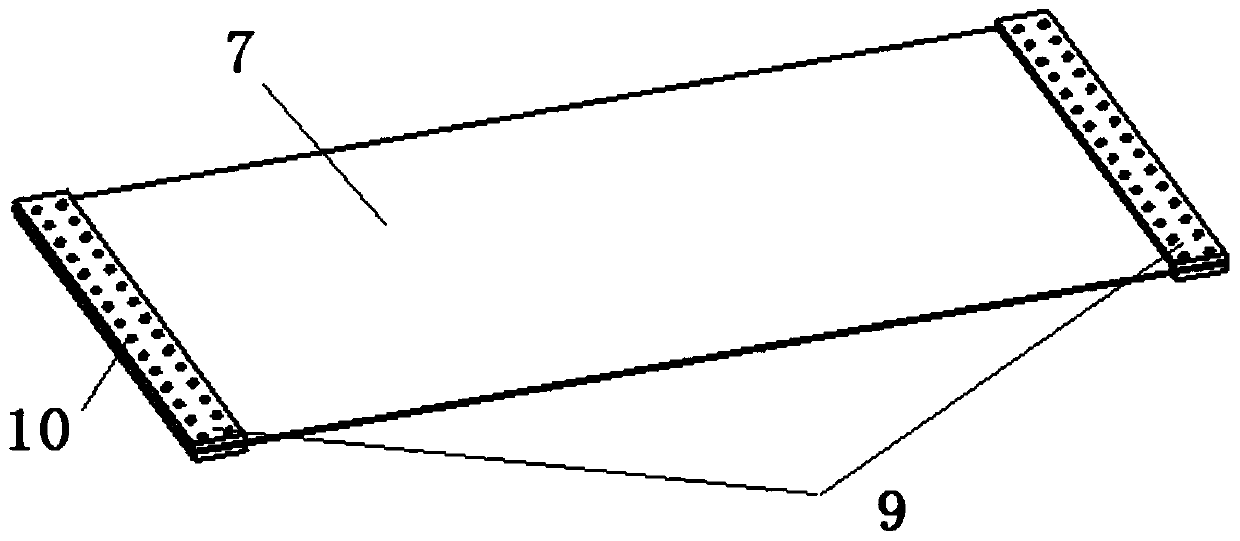

[0028] Such as figure 2 As shown, a titanium alloy sheet thermal stretch forming tooling includes a bottom plate 1, a tripod 2, a clamp 3, a main shaft 4, a three-section spacer 5, a buckle 6 and a drawing half-mold 8;

[0029] The tripods 2 are in the shape of a right triangle, eight in total, hollowed out in the middle, symmetrically arranged on both sides of the base plate 1, the tripods 2 on the same side are evenly spaced, and the horizontal right-angled sides of the tripod 2 are screwed to the base plate 1. The upper end of the vertical leg of the tripod 2 is provided with a circular hole, and the main shaft 4 passes through the circular hole successively to realize the fixing of the top of the tripod 2; the middle part of the vertical leg of the tripod 2 is provided with a through hole. Through the through ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com