Grinding head component of high-speed fine grinding linear bilateral edging machine

An edger and fine-grinding technology, which is used in the parts of grinding machine tools, machine tools suitable for grinding workpiece edges, and grinding racks, etc. Bottom edge polishing cannot automatically compensate for problems such as burning glass, so as to improve rigidity, avoid vibration lines and reduce vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

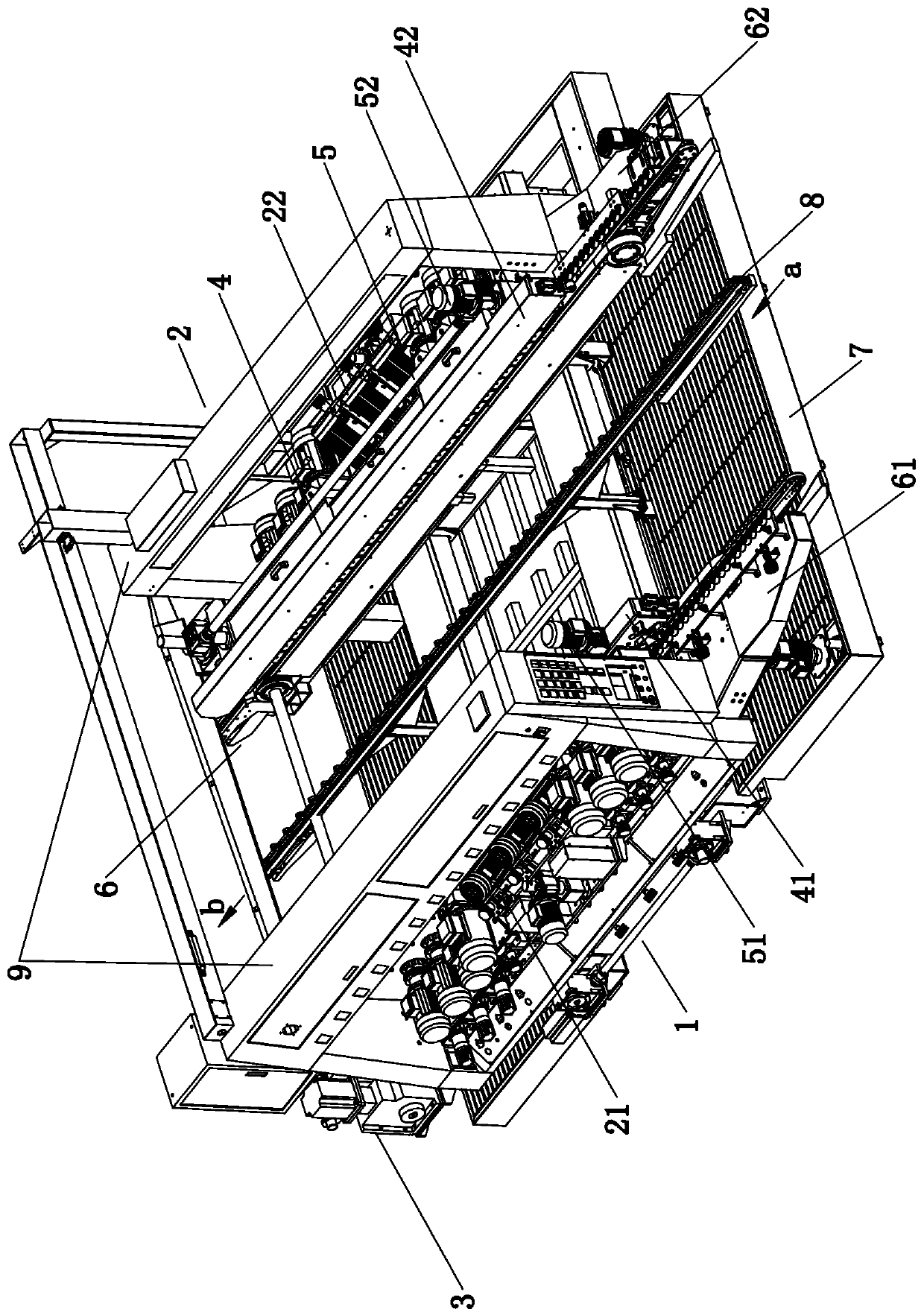

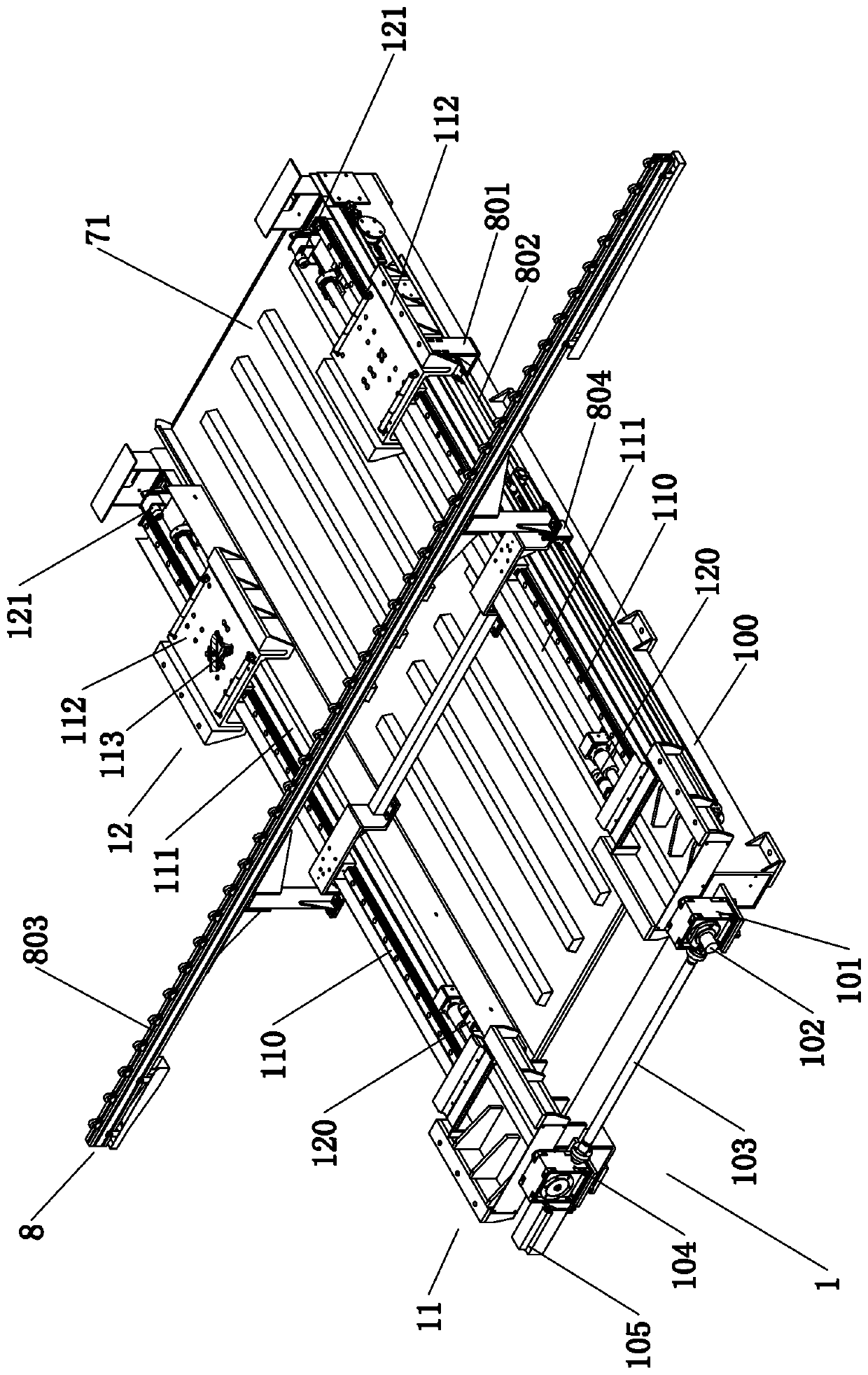

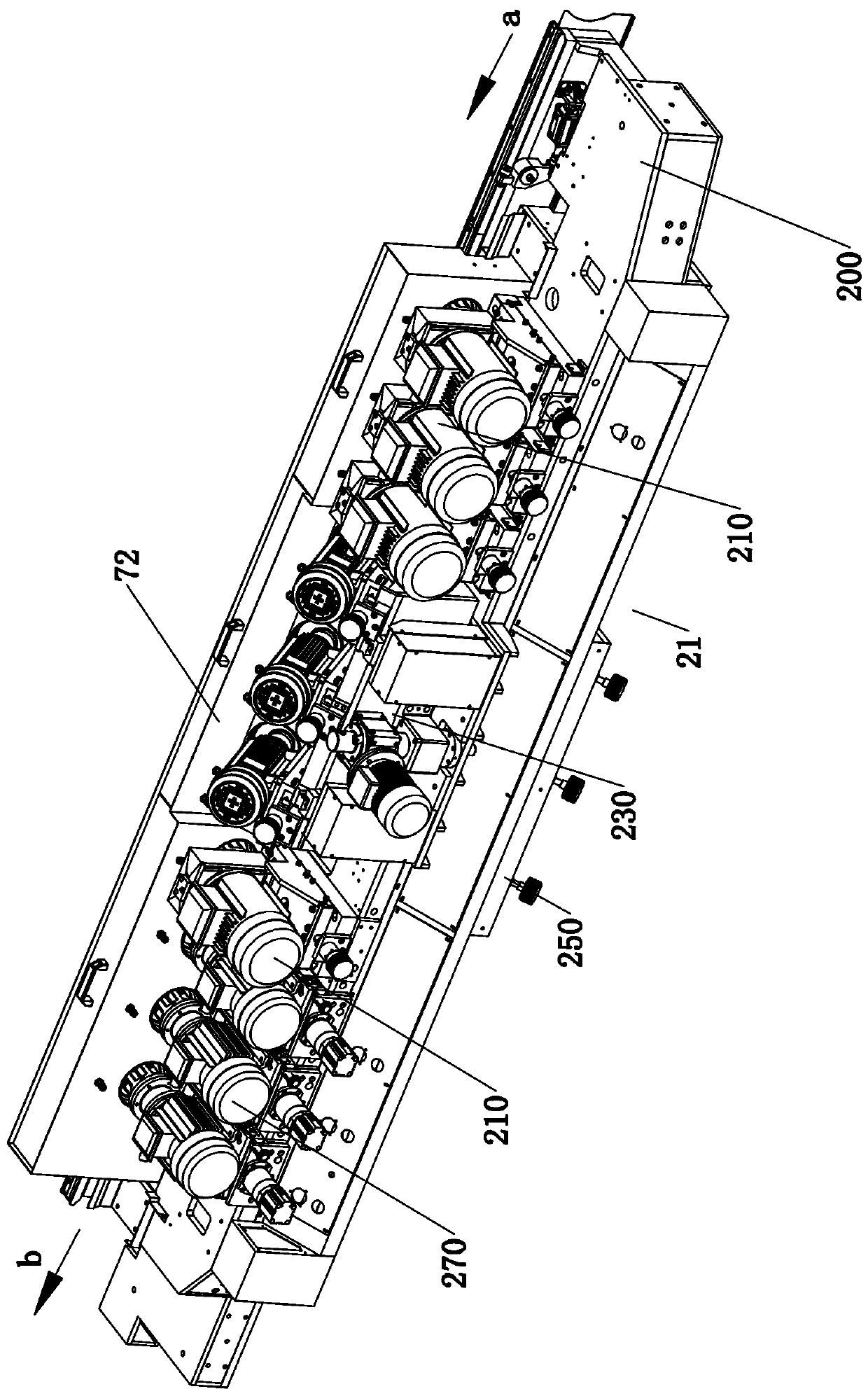

[0039] see figure 1 , combine Figure 3 to Figure 11 As shown, a grinding head part of a high-speed fine grinding linear bilateral edging machine includes a box grinding wheel group arrangement mechanism 2, and the box body grinding wheel group arrangement mechanism 2 is divided into a fixed end box body grinding wheel group arrangement mechanism 21 and a movable end box Body grinding wheel group arrangement mechanism 22, the fixed end box body grinding wheel group arrangement mechanism 21 and the moving end box body grinding wheel group arrangement mechanism 22 both include thirteen sets of grinding heads and box guide rails 200, of which four sets of grinding heads 210 are used for Bottom rough and fine grinding, three sets of grinding heads 230 are used for grinding and polishing the upper 45° chamfer, three sets of grinding heads 250 are used for g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com