Packer rubber barrel die device and rubber barrel preparing method

A packer and rubber cartridge technology, which is applied in the field of seal manufacturing, can solve the problems of easy fracturing of the rubber cartridge, loss of the setting function of the rubber cartridge, and failure of the use of the packer, so as to achieve convenient processing, improve product quality, Reasonable effect of structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

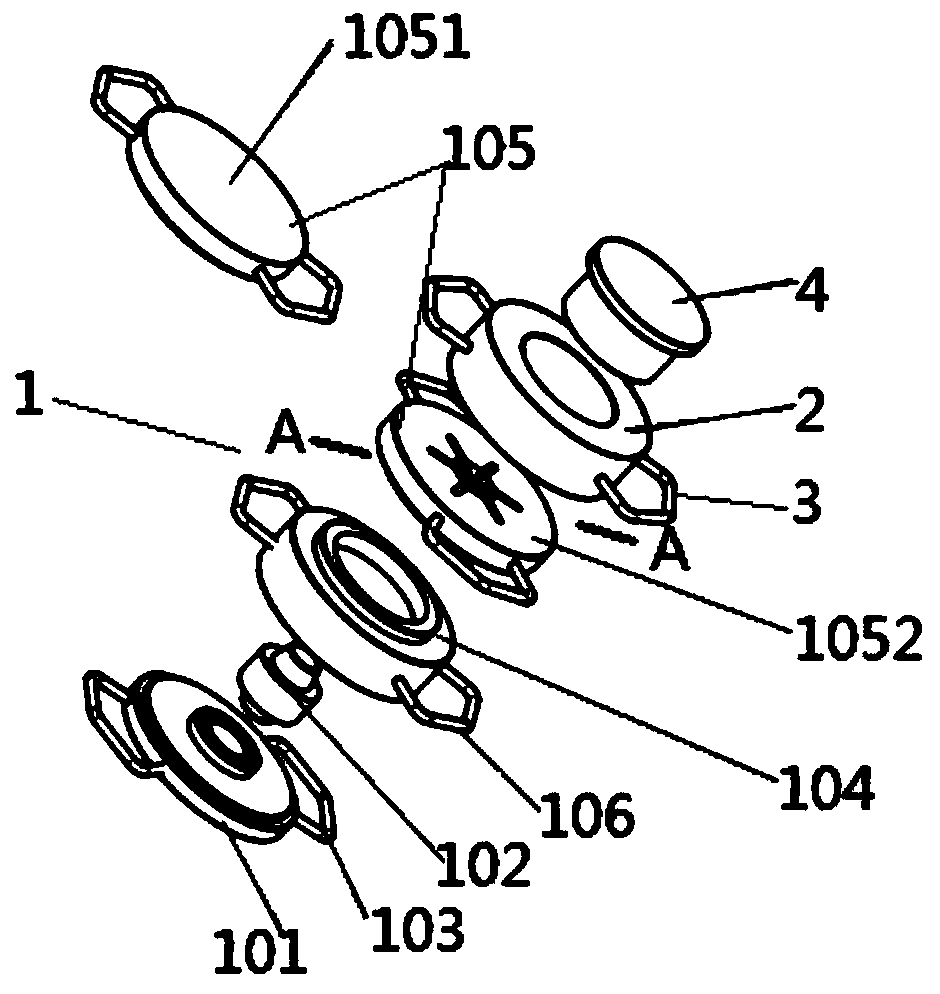

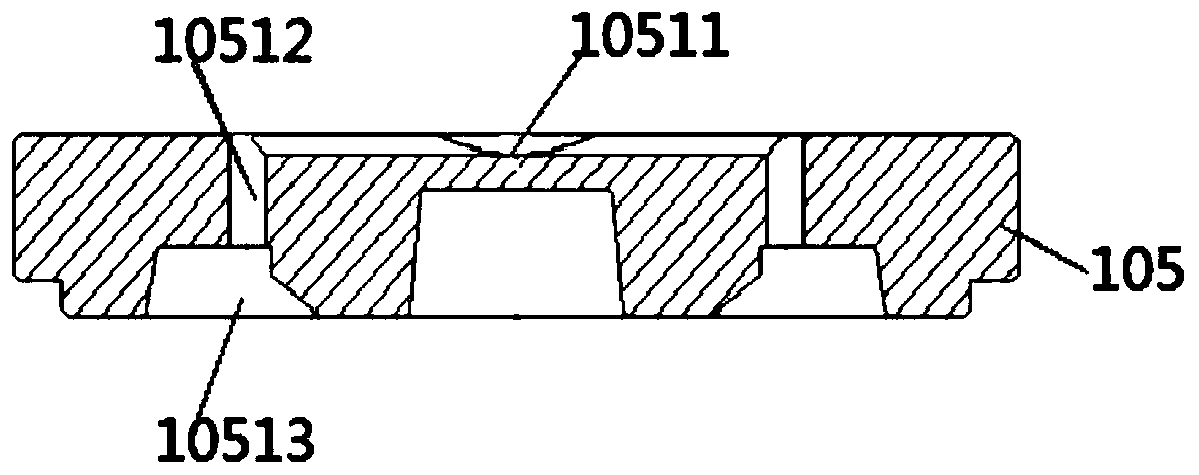

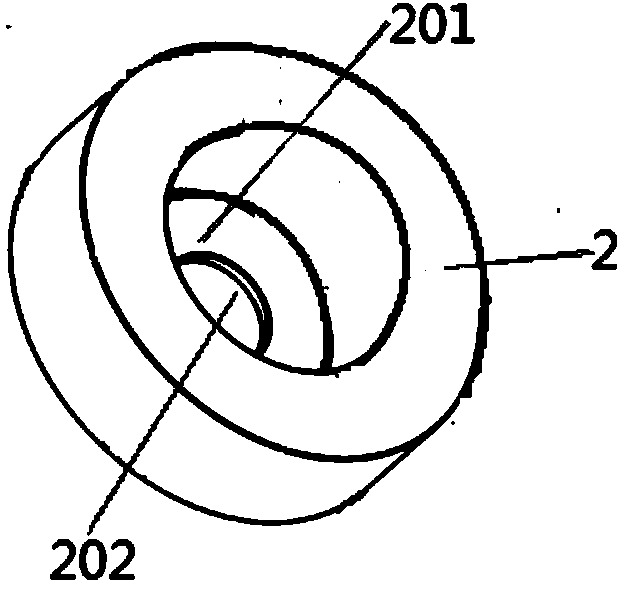

[0022] Such as Figure 1~Figure 3 A packer rubber cylinder mold device shown includes: a rubber cylinder forming mold 1, the upper part of the rubber cylinder forming mold 1 is provided with a rubber injection cylinder 2, and the rubber injection cylinder 2 is a hollow cylinder structure, the A pair of handles I3 are symmetrically connected to both sides of the injection cylinder 2, and a pressure injection head 4 is provided inside the injection cylinder 2, and the pressure injection head 4 can be freely separated from the injection cylinder 2, and the rubber cylinder forming mold 1 includes Lower formwork 101, mold core 102, handle II 103, middle formwork 104, upper formwork 105 and handle III 106, the upper part of the lower formwork 101 is connected to the lower end of the mold core 102, and a pair of handles II 103 are arranged symmetrically on both sides, and the mold core 102 is located in the middle Inside the formwork 104, the upper part of the middle formwork 104 is ...

Embodiment 2

[0031] Such as Figure 1~Figure 3 A packer rubber cylinder mold device shown includes: a rubber cylinder forming mold 1, the upper part of the rubber cylinder forming mold 1 is provided with a rubber injection cylinder 2, and the rubber injection cylinder 2 is a hollow cylinder structure, the A pair of handles I3 are symmetrically connected to both sides of the injection cylinder 2, and a pressure injection head 4 is provided inside the injection cylinder 2, and the pressure injection head 4 can be freely separated from the injection cylinder 2, and the rubber cylinder forming mold 1 includes Lower formwork 101, mold core 102, handle II 103, middle formwork 104, upper formwork 105 and handle III 106, the upper part of the lower formwork 101 is connected to the lower end of the mold core 102, and a pair of handles II 103 are arranged symmetrically on both sides, and the mold core 102 is located in the middle Inside the formwork 104, the upper part of the middle formwork 104 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com