High quality heavy sodium carbonate crystallization technology

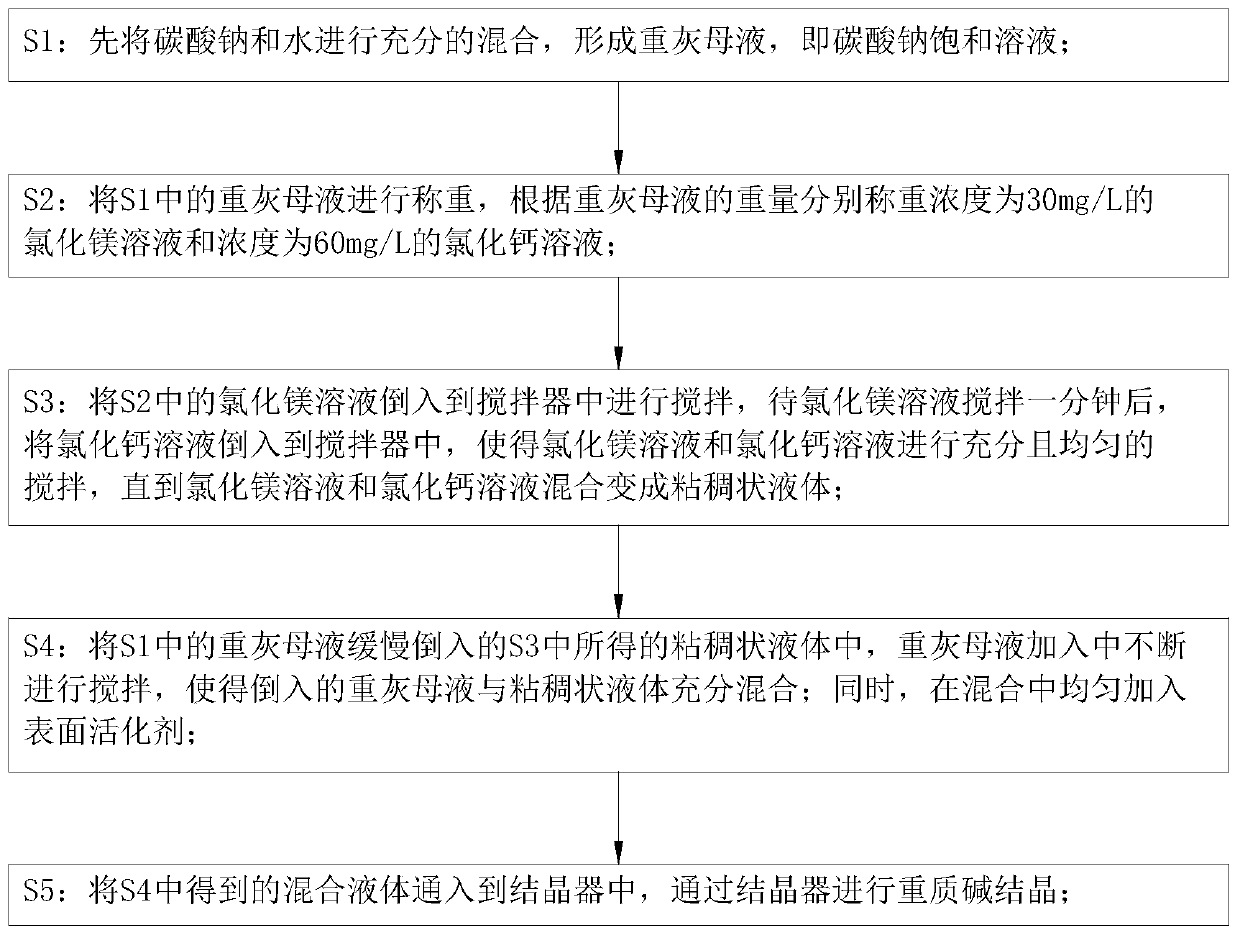

A technology with heavy alkali and craftsmanship, which is used in the field of high -quality heavy alkali crystalline craftsmanship, can solve problems such as the granularity and whiteness effect of heavy alkali crystals, and achieve the effects of diverse functions, extensive market demand, and huge economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

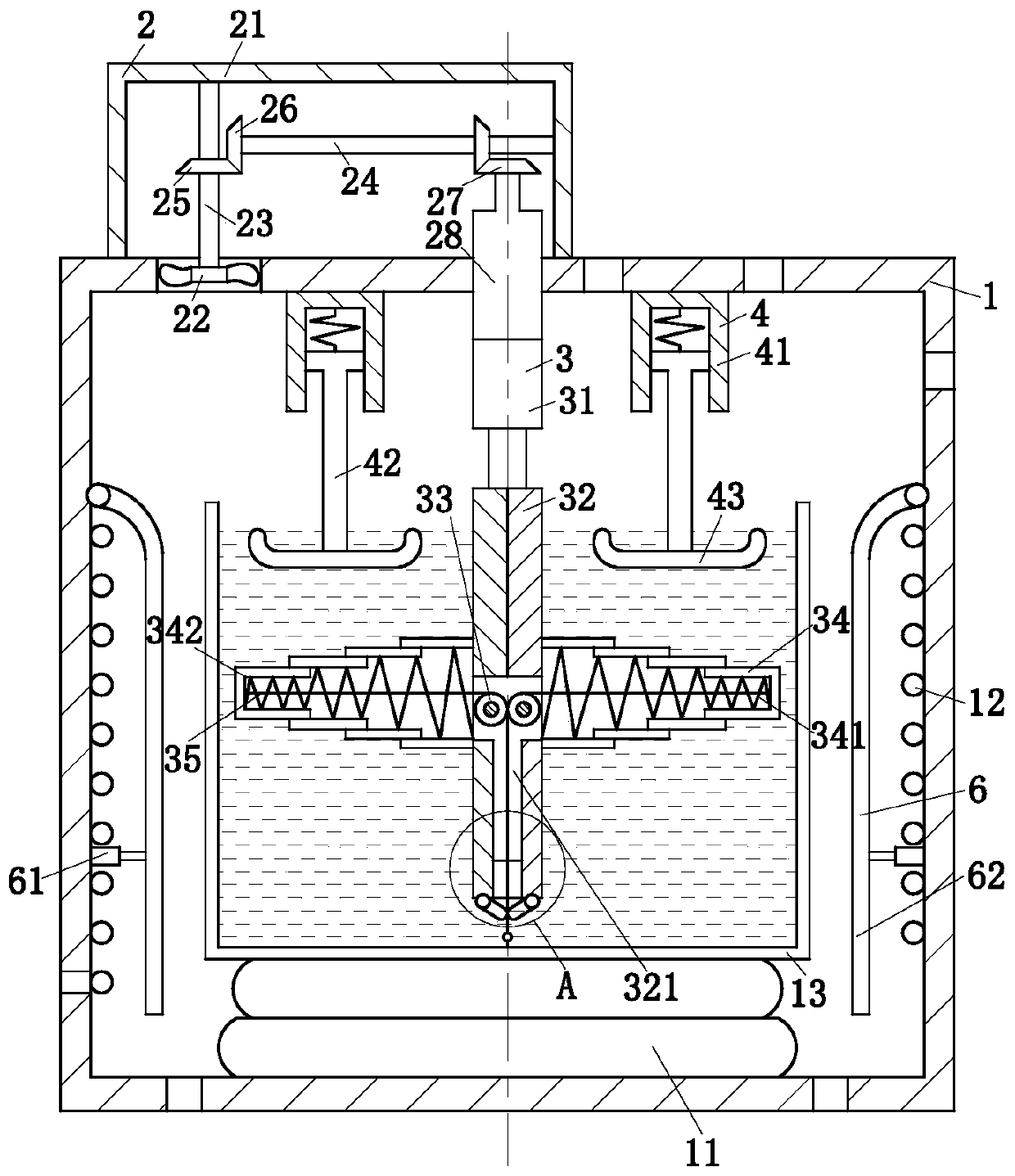

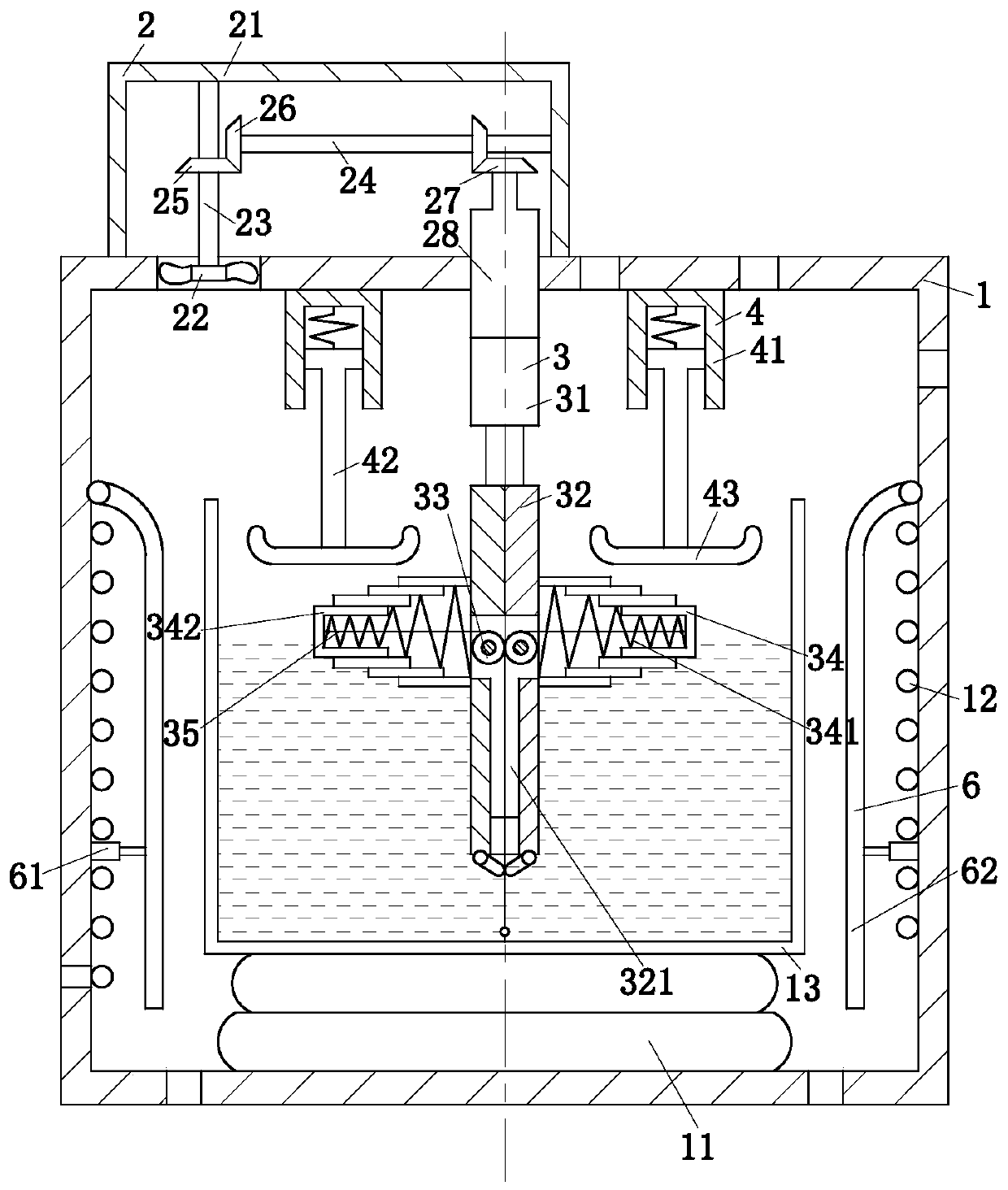

[0038] As an embodiment of the present invention, the steel wire cross section of the No. 1 spring 341 is rectangular, and the No. 1 spring 341 with a rectangular steel wire cross section cooperates with the square frame body 342 to improve the stability of the square frame body 342 when it shrinks. . In the present invention, the steel wire cross section of the No. 1 spring 341 is set as a rectangle, and the No. 1 spring 341 with a rectangular cross section moves with the square frame. On the one hand, the strength of the agitator 34 is improved; on the other hand, the Stirrer 34 aids in the stability of the soda ash crystals.

[0039] As an embodiment of the present invention, the No. 1 channel 321 is provided with a sealing unit 5; the sealing unit 5 is used to prevent the soda liquid from entering the No. 1 channel 321, and the sealing unit 5 is a high temperature resistant elastic bag 51; the high-temperature-resistant elastic bag 51 is a rectangular bag, and the high-te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com