EPDM heat-insulation layer material, and preparation method and application thereof

A thermal insulation layer and rubber technology, which is applied in the field of EPDM thermal insulation materials, can solve the problems of low strength, easy damage, and time-consuming unvulcanized rubber of the thermal insulation layer, and achieve excellent process performance, excellent mechanical properties, and high construction accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

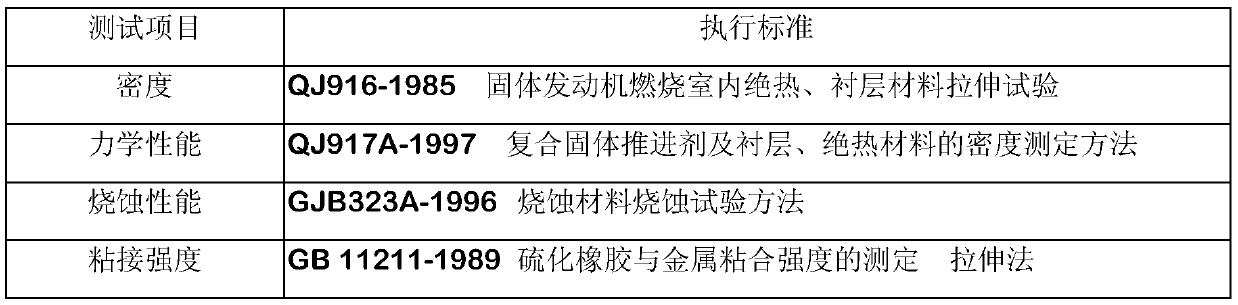

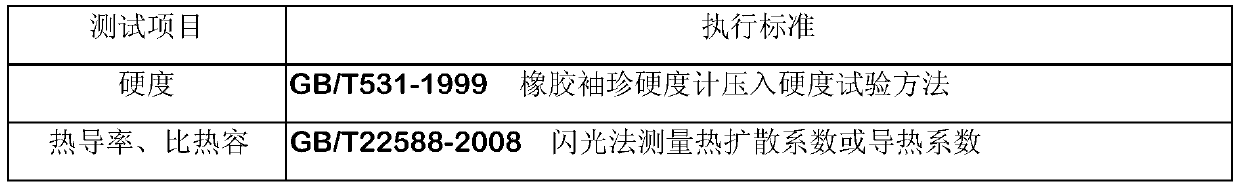

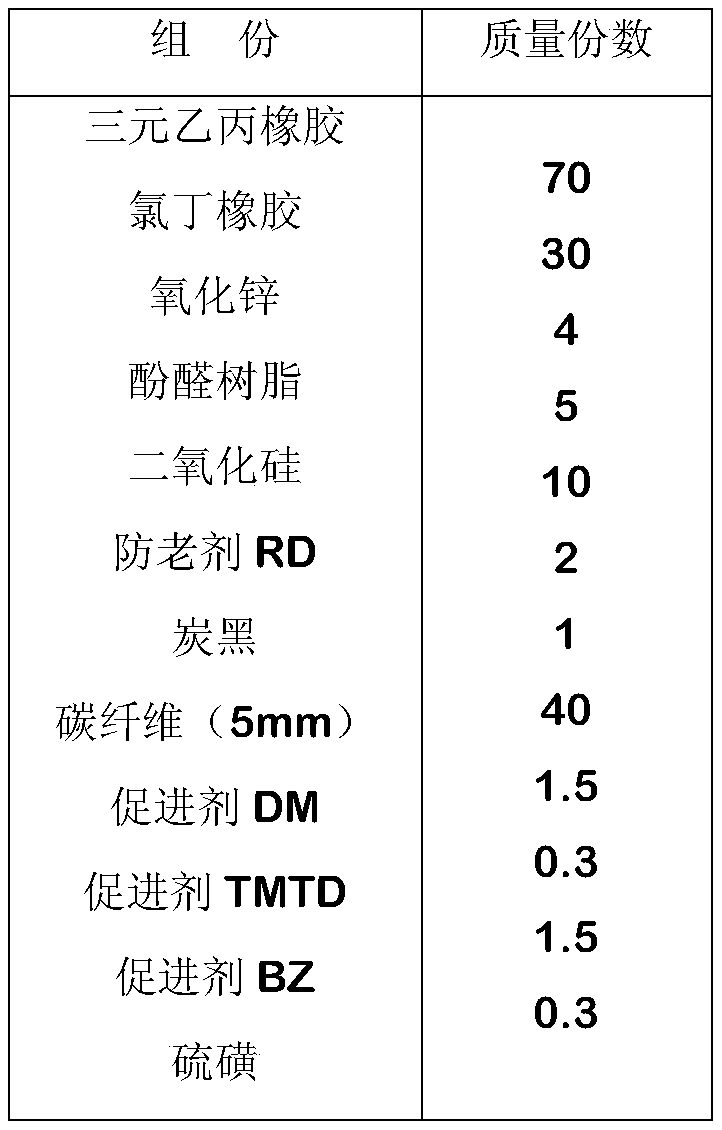

[0040] The formula composition of EPDM insulation layer material is as shown in table 1;

[0041] Table 1 is the formula composition of EPDM insulation layer material in embodiment 1

[0042]

[0043] The preparation method is as follows:

[0044] The above-mentioned components are weighed according to the proportions in the table, and the weighed components are mixed with a double-roller open mill or an internal mixer according to the general rubber mixing process, then thinned and released, and then in (150 ~160)℃×5MPa×30min for vulcanization molding, used for performance test of thermal insulation layer.

[0045] The performance of the obtained EPDM insulation layer material is as shown in table 2;

[0046] The performance of the EPDM insulation layer material prepared by the embodiment 1 of table 2

[0047]

[0048] The EPDM raw rubber wrapping tape with a cross-sectional size of 40mm×1.5mm was prepared by using the heat insulating layer compounded rubber of Examp...

Embodiment 2

[0053] The formula composition of EPDM insulation layer material is as shown in table 4;

[0054] Table 4 is the formula composition of EPDM insulation layer material in embodiment 2

[0055]

[0056] Preparation method, with embodiment 1.

[0057] The performance of the obtained EPDM insulation layer material is as shown in table 5;

[0058] The performance of the EPDM insulation layer material prepared by the embodiment 2 of table 5

[0059]

[0060] The EPDM raw rubber winding tape with a cross-sectional size of 40mm×1.5mm was prepared with a calender using the heat-insulating layer compounded rubber of Example 2, and the length was about 50m. The properties of the winding tape are shown in Table 6;

[0061] Table 6 Properties of Wrapping Tape for Thermal Insulation Layer (Before Vulcanization)

[0062]

[0063] Wrap the above-mentioned EPDM raw tape on the engine mandrel, the winding tension is about 100N, and the thickness of the insulation layer is 3mm. Afte...

Embodiment 3

[0065] The formula composition of EPDM insulation layer material is as shown in table 7;

[0066] Table 7 is the formula composition of EPDM insulation layer material in embodiment 3

[0067]

[0068]

[0069] Preparation method, with embodiment 1.

[0070] The performance of the obtained EPDM insulation layer material is as shown in table 8;

[0071] The performance of the EPDM insulation layer material prepared by the embodiment 3 of table 8

[0072]

[0073] The EPDM raw rubber wrapping tape with a cross-sectional size of 40mm×1.5mm was prepared with a calender using the heat-insulating layer compounded rubber of Example 3. The properties of the winding tape are shown in Table 9;

[0074] Table 9 Properties of Wrapping Tape for Thermal Insulation Layer (Before Vulcanization)

[0075]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Winding tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com