A kind of ultraviolet curing type antifouling toughened high temperature resistant coating and preparation method thereof

A high temperature resistant coating and curing technology, applied in antifouling/underwater coatings, polyurea/polyurethane coatings, coatings, etc. The effect of fingerprint performance, high gloss and transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment provides a UV-curable anti-fouling, toughened and high-temperature-resistant coating, which includes the following components by mass percentage:

[0031] raw material Mass percentage (%) polyurethane acrylic resin BEAMSET 1402 30% Functional I Acrylic Monomer 6150 5% Functional II Acrylic Monomer EM2204 25% Reactive diluent (tripropylene glycol diacrylate) 5% Organic solvent (toluene / n-butanol=50 / 50, mass meter) 30% Photoinitiator (DAROCUR 1173) 3% Leveling agent BYK-333 0.5% Anti-aging agent 168 0.5% Light stabilizer UV-531 0.5% Other additives 0.5%

[0032] The preparation method of above-mentioned coating specifically comprises the following steps:

[0033] Weigh the raw materials according to the formula of the above paint; then, add BEAMSET 1402, 6150, EM2204 into the reaction kettle in turn, heat at 55°C and stir for 25min; 50 organic solvent, stir at 1000 rpm for 25 minute...

Embodiment 2

[0038] This embodiment provides a UV-curable anti-fouling, toughened and high-temperature-resistant coating, which includes the following components by mass percentage:

[0039] raw material Mass percentage (%) polyurethane acrylic resin BEAMSET 1402 40% Functional I acrylic monomer EM210 10% Functional II Acrylic Monomer EM2204 10% Reactive diluent (neopentyl glycol diacrylate) 15% Organic solvent (ethyl acetate / n-butanol=50 / 50, by mass) 20% Photoinitiator (DAROCUR 1173) 3% Leveling agent BYK-333 0.5% Anti-aging agent JW-03-HH1020 0.5% Light stabilizer 783 0.5% Other additives 0.5%

[0040] The preparation method of above-mentioned coating specifically comprises the following steps:

[0041] Weigh the raw materials according to the formula of the above paint; then, add BEAMSET 1402, EM210, EM2204 into the reaction kettle in turn, heat at 50°C and stir for 30min; then add reactive diluents neopentyl glyc...

Embodiment 3

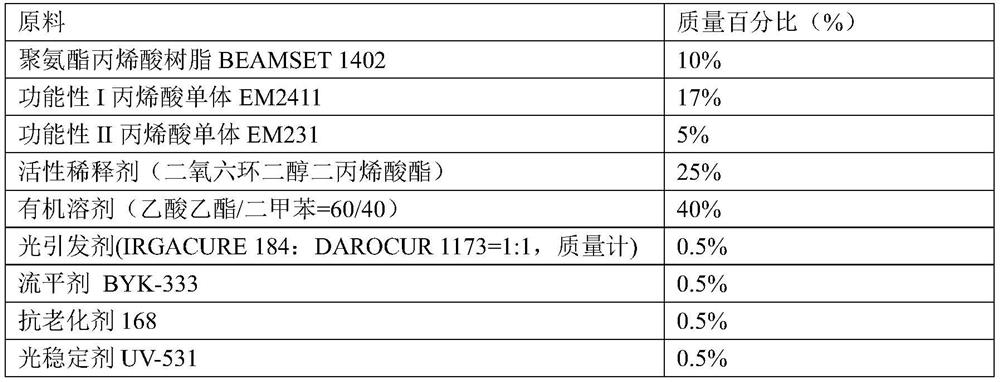

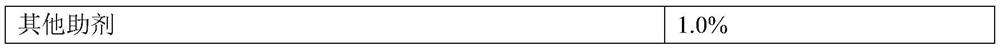

[0046] This embodiment provides a UV-curable anti-fouling, toughened and high-temperature-resistant coating, which includes the following components by mass percentage:

[0047]

[0048]

[0049] The preparation method of above-mentioned coating specifically comprises the following steps:

[0050] Weigh the raw materials according to the formula of the above paint; then, add BEAMSET 1402, EM2411, EM231 into the reaction kettle in turn, heat at 60°C and stir for 20min; then add reactive diluent dioxanediol diacrylate and ethyl acetate / di Organic solvent with a toluene ratio of 60 / 40, stirred at a low speed of 1500 rpm for 20 minutes; added photoinitiator and all additives to the stirred mixture obtained in the above steps, stirred at a medium speed of 3000 rpm for 50 minutes, and mixed well The antifouling toughened high temperature resistant coating is obtained.

[0051] The method for coating and curing the above-mentioned anti-fouling, toughening and high-temperature-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com