C6 stain-release environment-friendly anti-flaming fabric dyeing and finishing technology

A flame-retardant fabric, easy decontamination finishing technology, applied in the field of dyeing and finishing technology, can solve the problems that cannot meet the requirements of flame retardant, environmental protection, and easy decontamination at the same time, achieve easy decontamination finishing, reduce flame retardant effect, and flame retardant effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

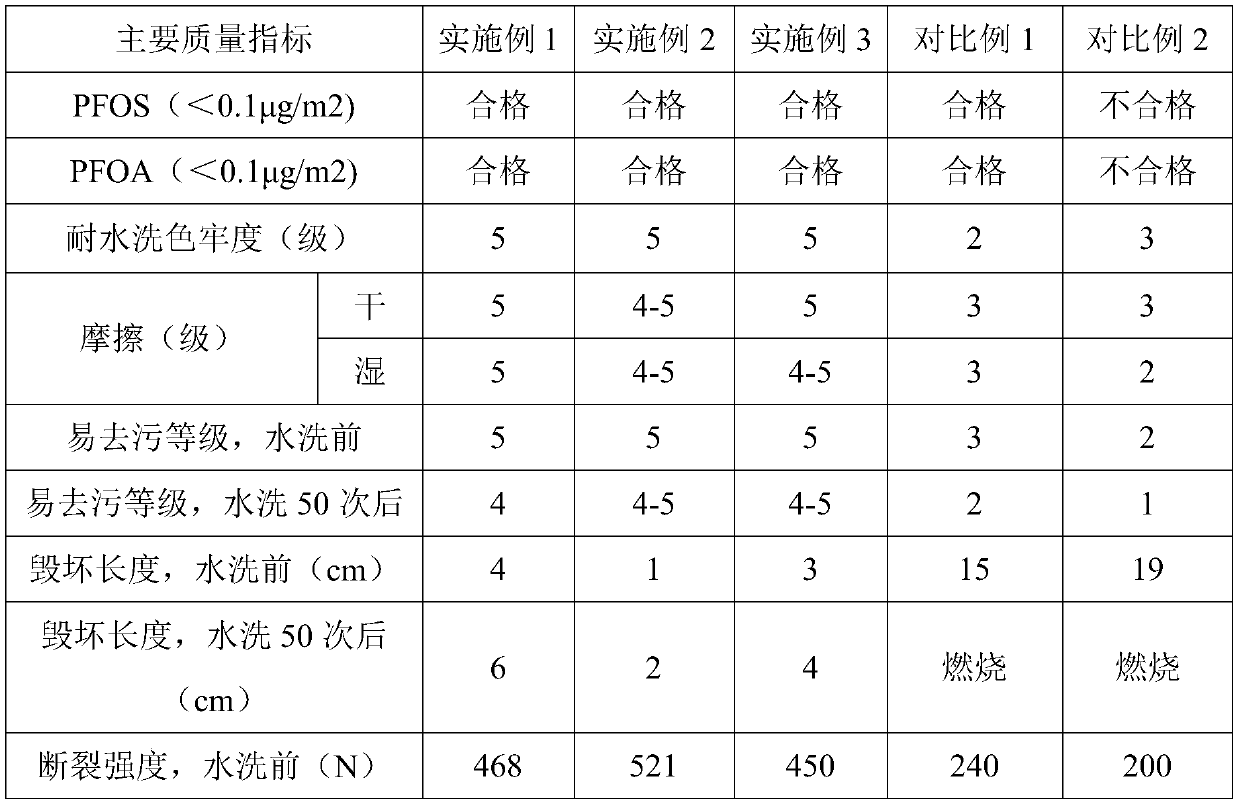

Examples

Embodiment 1

[0027]A kind of dyeing and finishing process of C6 easy decontamination, environmental protection, flame retardant fabric, described process comprises the following steps carried out in order:

[0028] Gray fabric pretreatment → dyeing → flame retardant finishing → easy decontamination finishing → tenter → preshrinking, wherein the decontamination finishing agent used in the decontamination finishing process is SR-88Y finishing agent.

[0029] The easy decontamination finishing process includes the following processing steps: removing various surfactants on the fabric, washing the fabric, drying → padding the fabric with the easy decontamination finishing solution, with a residual rate of 50% → pre-drying the fabric at a temperature of 100 ℃, time 1min → bake fabric, temperature 150℃, time 0.5min.

[0030] The concentration of the decontamination finishing agent in the decontamination finishing liquid is: 30g / L, and the fabric is a cotton / polyester blended fabric.

[0031] Th...

Embodiment 2

[0034] A kind of dyeing and finishing process of C6 easy decontamination, environmental protection, flame retardant fabric, described process comprises the following steps carried out in order:

[0035] Gray fabric pretreatment → dyeing → flame retardant finishing → easy decontamination finishing → tenter → preshrinking, wherein the decontamination finishing agent used in the decontamination finishing process is SR-88Y finishing agent.

[0036] The easy decontamination finishing process includes the following processing steps: removing various surfactants on the fabric, washing the fabric, drying → padding the fabric with the easy decontamination finishing solution, the excess rate is 55%, and the fabric is pre-baked at a temperature of 105°C , time 1.5min → bake fabric, temperature 155 ℃, time 2.5min.

[0037] The concentration of the decontamination finishing agent in the decontamination finishing liquid is: 50g / L, and the fabric is pure cotton fabric.

[0038] The flame re...

Embodiment 3

[0041] A kind of dyeing and finishing process of C6 easy decontamination, environmental protection, flame retardant fabric, described process comprises the following steps carried out in order:

[0042] Gray fabric pretreatment → dyeing → flame retardant finishing → easy decontamination finishing → tenter → preshrinking, wherein the decontamination finishing agent used in the decontamination finishing process is SR-88Y finishing agent.

[0043] The easy decontamination finishing process includes the following processing steps: removing various surfactants on the fabric, washing the fabric, drying → padding the fabric with the easy decontamination finishing solution, the excess rate is 60% → pre-drying the fabric at a temperature of 110 ℃, time 2min→baking fabric, temperature 170℃, time 3min.

[0044] The concentration of the decontamination finishing agent in the decontamination finishing liquid is: 70g / L, and the fabric is cotton-polyester fabric.

[0045] The flame retardan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com