Modified nylon for body armor

A technology of modified nylon and body armor, applied in the field of modified nylon, which can solve the problems of easy hydrolysis and product performance to be improved, and achieve the effect of ultra-high impact resistance, strong impact resistance and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A modified nylon for body armor is composed of the following materials: cross-linked polymer, nylon 1010, nano silicon carbide, titanium dioxide whiskers and antioxidant 1010.

[0024] The ratio by weight of nylon 1010: cross-linked polymer: nano-silicon carbide: titanium dioxide whiskers: antioxidant 1010 is 9.0:1:0.5:0.5:0.05.

[0025] Wherein the cross-linked polymer is made of ultra-high molecular weight polyethylene (UHMWPE), polyamide I, and cumene peroxide (DCP) in a molar ratio of 1:1:0.05, and the method is as follows:

[0026] Use a small amount of absolute ethanol to mix a certain mass of UHMWPE and polyamide I at 60°C for 30 minutes, then add DCP, keep it warm for 1 hour, wash and dry to obtain a cross-linked polymer.

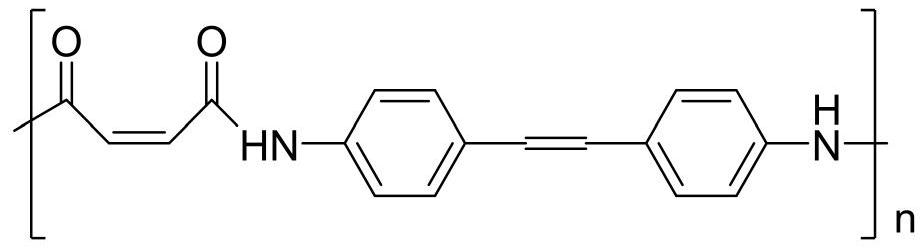

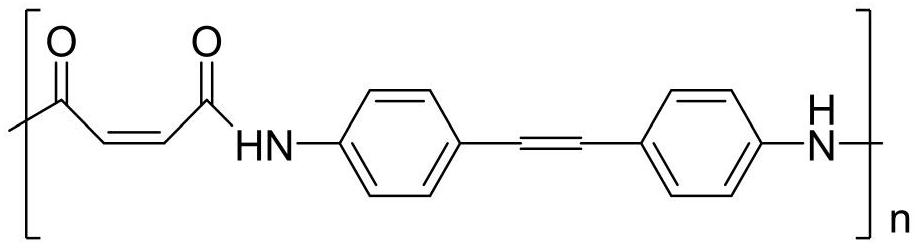

[0027] The structural formula of the polyamide I is as follows:

[0028]

[0029] n is 100

[0030] The preparation method of the modified nylon used for body armor is as follows:

[0031] Step 1: Drying: Dry the cross-linked polymer, n...

Embodiment 2

[0035] A modified nylon for body armor is composed of the following materials: cross-linked polymer, nylon 1010, nano silicon carbide, titanium dioxide whiskers and antioxidant 1010.

[0036] The ratio by weight of nylon 1010: cross-linked polymer: nano-silicon carbide: titanium dioxide whiskers: antioxidant 1010 is 8.8:1:0.5:0.5:0.05.

[0037] The cross-linked polymer is made of ultra-high molecular weight polyethylene (UHMWPE), polyamide I, and cumene peroxide (DCP) at a molar ratio of 1:1:0.05, and the method is as follows:

[0038] Use a small amount of absolute ethanol to mix a certain quality of UHMWPE and polyamide I uniformly at 60°C and stir for 30 minutes, add DCP, keep it warm for 1 hour, wash and dry to obtain a cross-linked polymer.

[0039] The structural formula of the polyamide I is as follows:

[0040]

[0041] n is 100

[0042] The preparation method of the modified nylon used for body armor is as follows:

[0043] Step 1: Drying: Dry the cross-linked p...

Embodiment 3

[0047] A modified nylon for body armor is composed of the following materials: cross-linked polymer, nylon 1010, nano silicon carbide, titanium dioxide whiskers and antioxidant 1010.

[0048] The ratio by weight of nylon 1010: cross-linked polymer: nano-silicon carbide: titanium dioxide whiskers: antioxidant 1010 is 8.6:1:0.5:0.5:0.05.

[0049] The cross-linked polymer is made of ultra-high molecular weight polyethylene (UHMWPE), polyamide I, and cumene peroxide (DCP) at a molar ratio of 1:1:0.05, and the method is as follows:

[0050] Use a small amount of absolute ethanol to mix a certain quality of UHMWPE and polyamide I uniformly at 60°C and stir for 30 minutes, add DCP, keep it warm for 1 hour, wash and dry to obtain a cross-linked polymer.

[0051] The structural formula of the polyamide I is as follows:

[0052]

[0053] n is 100

[0054] The preparation method of the modified nylon used for body armor is as follows:

[0055]Step 1: Drying: Dry the cross-linked po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com