A self-resetting shock-absorbing structure of center pillars and arc-shaped rubber bearings in assembled subway stations

A technology for rubber bearings and subway stations, which is applied in the field of shock absorption in subway stations, can solve the problems of poor shock absorption, unreliable force transmission, and inflexible rotation, so as to improve seismic resistance, reduce lateral displacement, and improve shock absorption. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

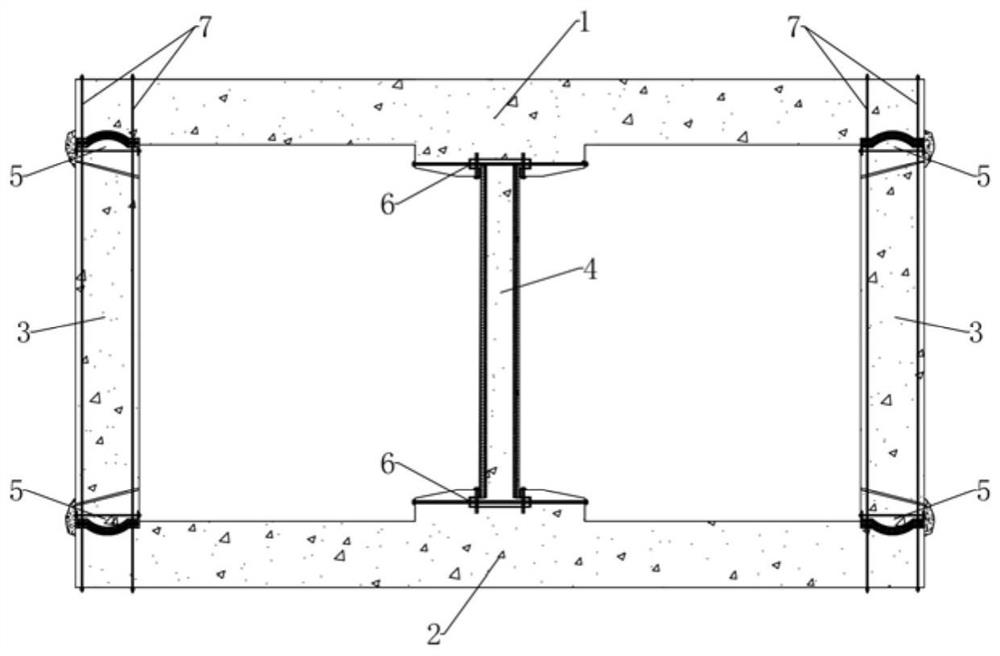

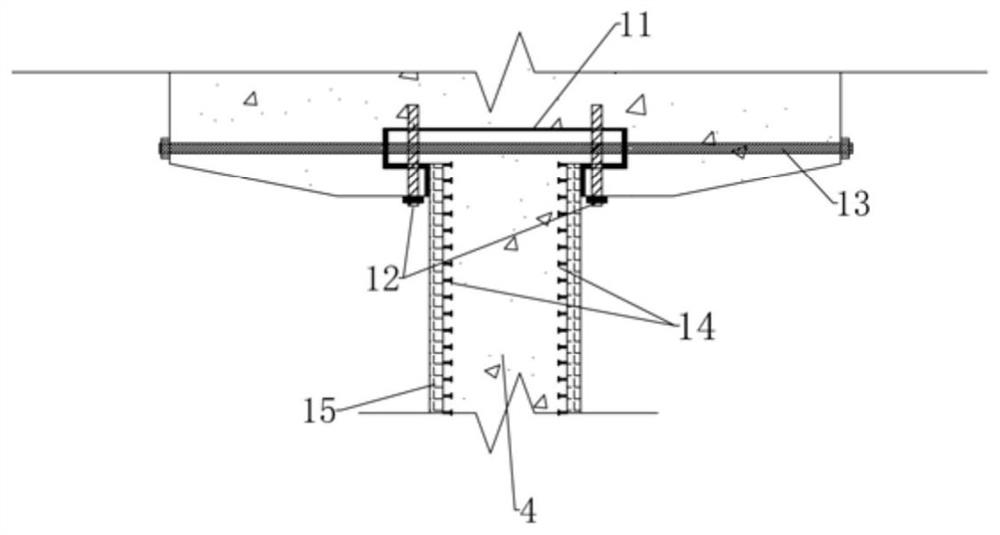

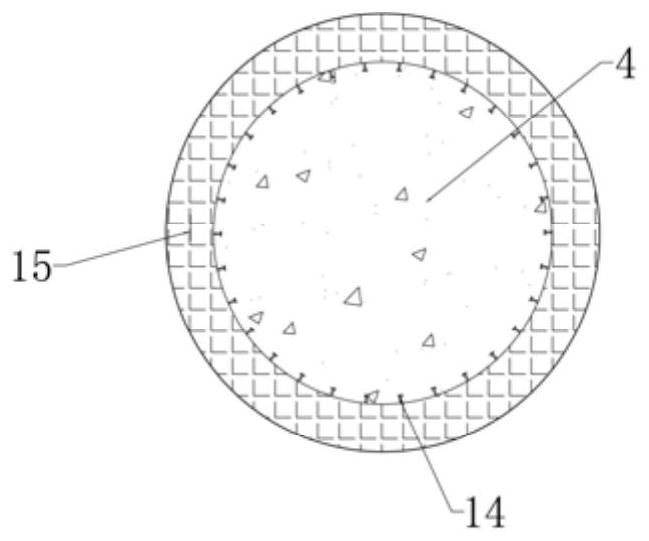

[0029] The prefabricated roof 1, prefabricated floor 2, prefabricated side wall 3, and prefabricated center column 4 are all prefabricated in the factory, the prefabricated side wall 3, the prefabricated bottom plate 2, and the prefabricated roof 1 are reserved for reinforcement channels, and the rubber cushion a5- 5. The curved steel plate a5-4 is fixed on the prefabricated side wall 3 through anchor bolts 5-6.

[0030] When installing:

[0031] The first step: anchor one end of the prestressed steel bar 7 on the prefabricated floor 2, and place the prefabricated floor 2 at a designated position with a lifting device;

[0032] Step 2: place rubber bearings on the prefabricated floor 2, and place the prefabricated side walls 3 on the rubber bearings;

[0033] The third step: place the rubber support on the upper end of the prefabricated side wall 3, and then carry out the docking and hoisting of the prefabricated roof 1 and the prefabricated side wall 3, the prefabricated roo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com