Efficient energy-saving heating boiler capable of being conveniently used by people

A high-efficiency energy-saving heating boiler technology, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of environmental pollution, waste of resources, slow heating rate, etc., to increase the heating area and increase the heating rate , the effect of slowing down the heat dissipation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

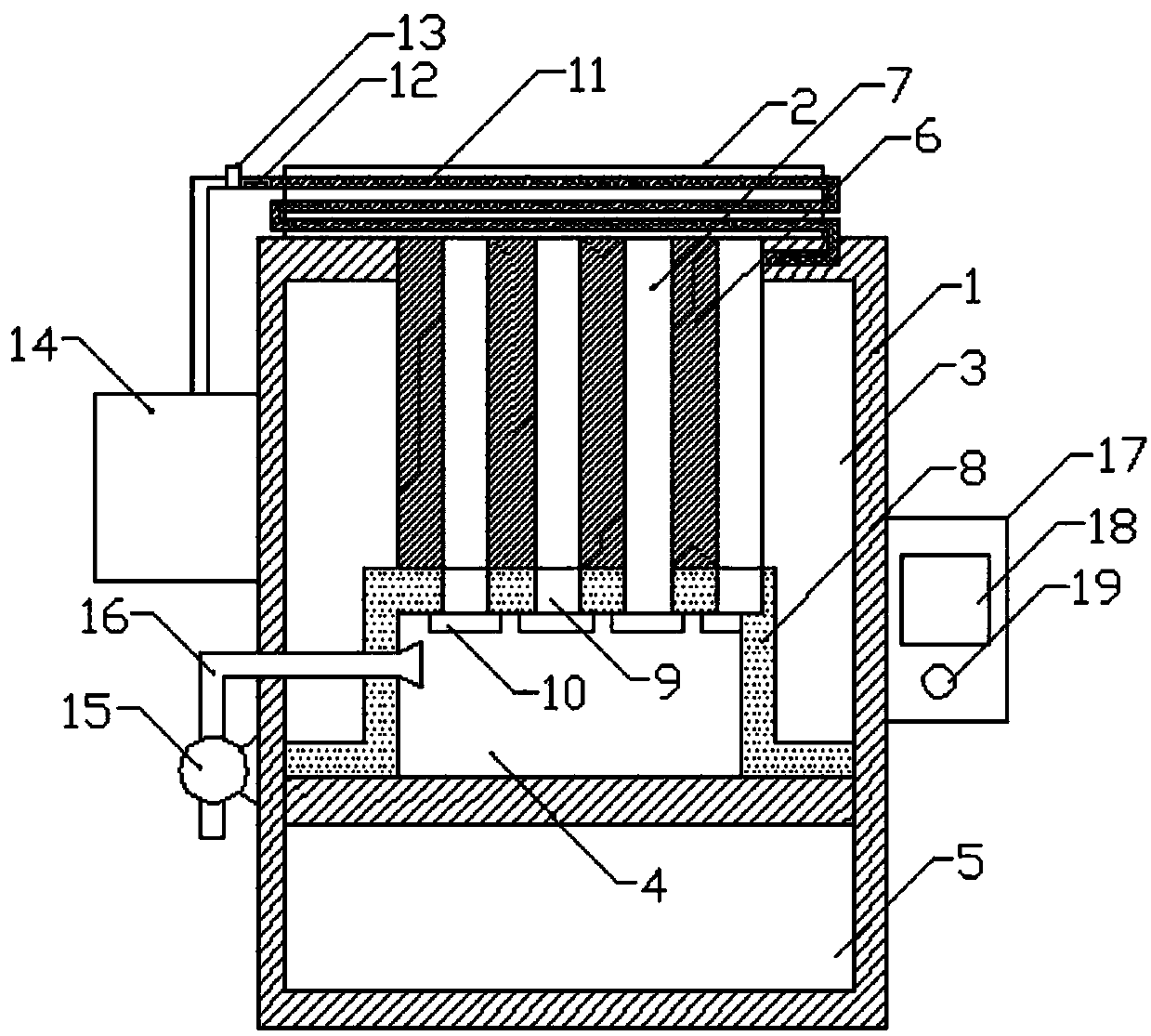

[0016] Such as figure 1 As shown, the present invention provides a high-efficiency energy-saving heating boiler that is convenient for people to use, including a boiler body 1 and a heat transfer tube 2, and the boiler body 1 is provided with a flame air flow heat exchange chamber 3, a combustion chamber 4 and an ash collection chamber 5, and The flame air flow heat exchange chamber 3, the combustion chamber 4 and the ash collection chamber 5 are arranged sequentially from top to bottom, the flame air flow heat exchange chamber 3 and the combustion chamber 4 are separated by a first partition 8, and the flame air flow heat exchange chamber 3 A number of water pipes 6 are evenly spaced, and an air inlet channel 7 is arranged between the water pipes 6, and the air inlet of the air inlet channel 7 communicates with the through hole 9 of the first partition 8, and the through hole 9 is provided with a filter Net 10, one end of the water pipe 6 is fixed on the first partition 8, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com