Device and method for automatically measuring geometric initial defects of structural member

A technology of geometric initial defects and structural components, applied in the field of measurement, can solve the problems of difficult operation, poor practicability, and inability to measure accurate measurement of special-shaped components, etc., and achieve the effect of high measurement accuracy and easy operation of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to facilitate the understanding of the present invention, the present invention will be described more fully and in detail below in conjunction with the accompanying drawings and preferred embodiments, but the protection scope of the present invention is not limited to the following specific embodiments.

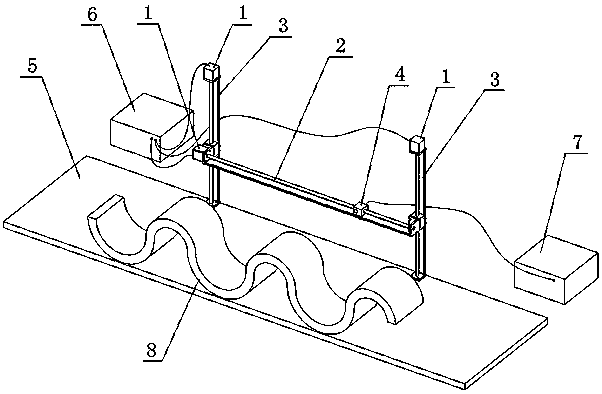

[0020] Such as figure 1 As shown, a device for automatically measuring initial geometric defects of structural components in the present invention includes a measurement system, a positioning control system 6 , a data acquisition system 7 and a measurement platform 5 .

[0021] The measurement system includes a laser displacement sensor 4, a stepper motor 1, an X-axis screw 2, a Y-axis screw 3, two Y-axis screw 3 are vertically fixed on the measurement platform 5, and the top of the Y-axis screw 3 Connect the stepper motor 1, the two ends of the X-axis screw 2 are respectively connected to the screw nuts set on the two Y-axis screw 3, one end of the X-axis sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com