Intelligent coal drawing method based on real-time monitoring of top coal thickness variation

A thickness change, real-time monitoring technology, applied in mine roof supports, measuring devices, earthwork drilling and other directions, can solve problems such as over-discharge or under-discharge, coal quality decline, resource loss, etc., to achieve remarkable effects, strong adaptability, Control accurate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the embodiments in the drawings:

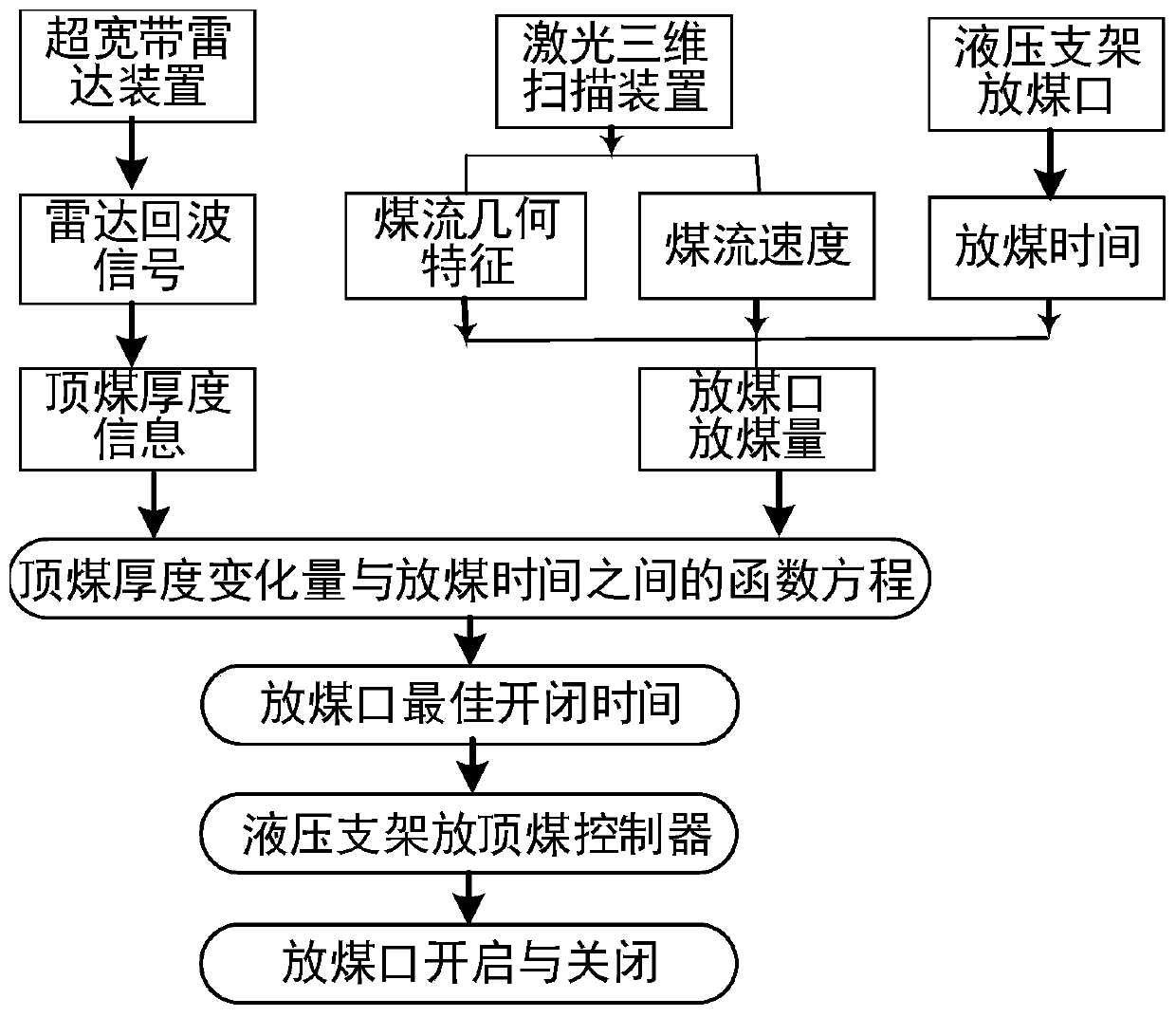

[0026] Such as figure 1 As shown, the intelligent coal caving method based on real-time monitoring of top coal thickness variation of the present invention uses ultra-wideband radar device 4 and laser three-dimensional scanning device 6 to monitor top coal thickness information in real time, and automatically adjusts coal caving according to top coal thickness variation The opening and closing time of the mouth, the specific steps include:

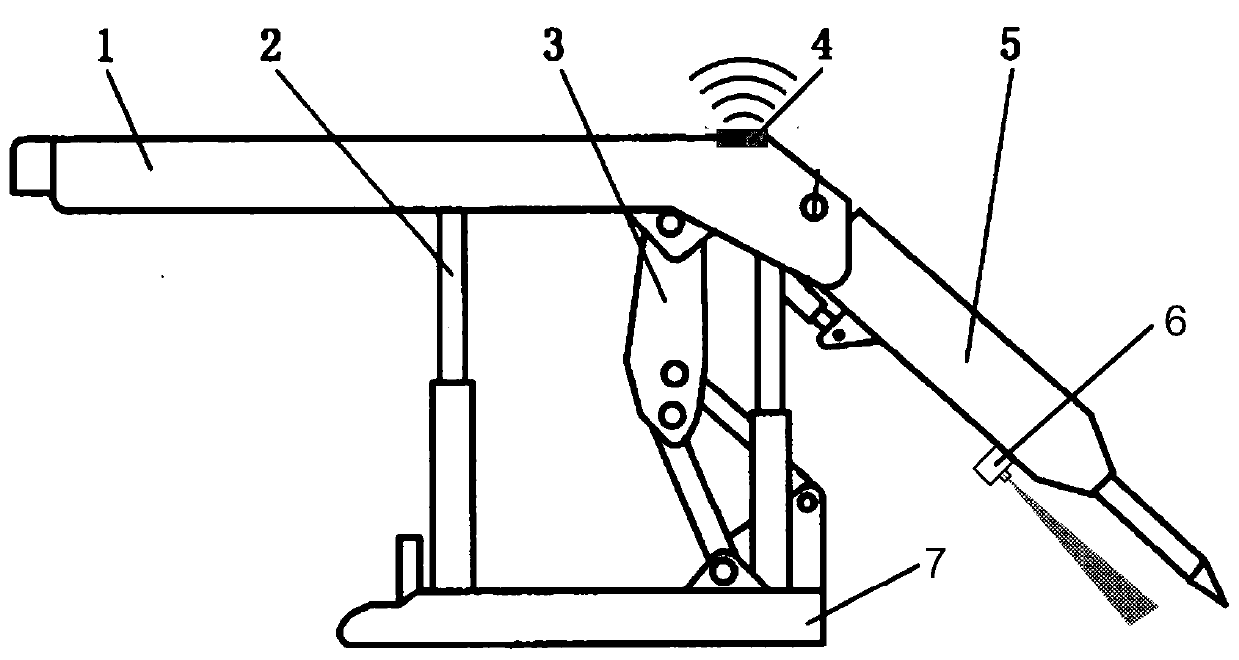

[0027] (1) The ultra-wideband radar device is installed on the top beam 1 of the hydraulic support near the middle and rear position. The ultra-wideband radar device 4 includes a transmitting device, a receiving device and a control machine connected in sequence; the hydraulic support includes a top beam 1. Vertical pole 2, shield beam 3, tail beam 5, base 7, controller and electro-hydraulic servo control system, top beam 1 is set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com