An intelligent fault diagnosis method suitable for pipe expansion equipment

A fault diagnosis and fault diagnosis model technology, applied in neural learning methods, instruments, biological neural network models, etc., can solve problems such as inability to guarantee the quality of all products, untimely manual monitoring, and quality consistency problems, so as to reduce labor costs. and signal analysis time, improve the recognition accuracy, and reduce the effect of computing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

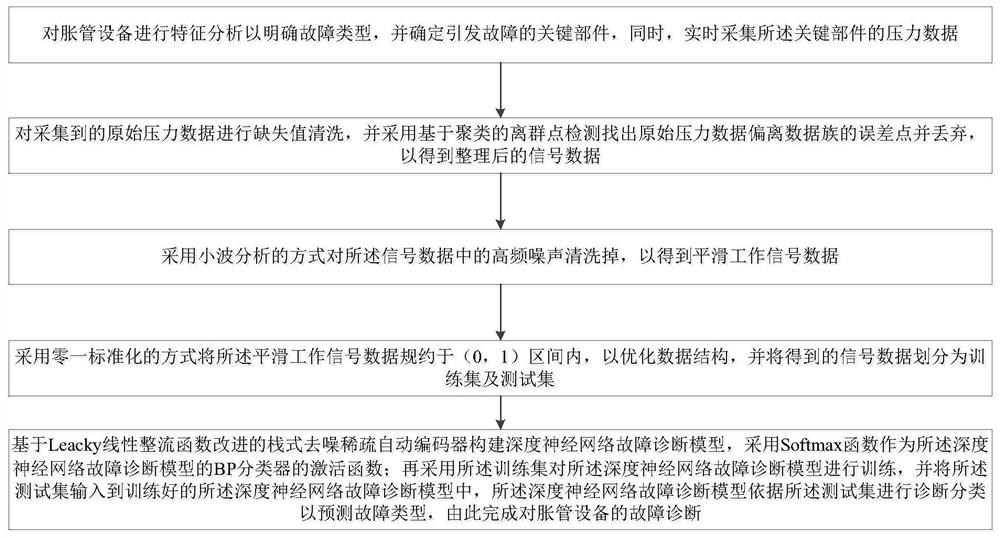

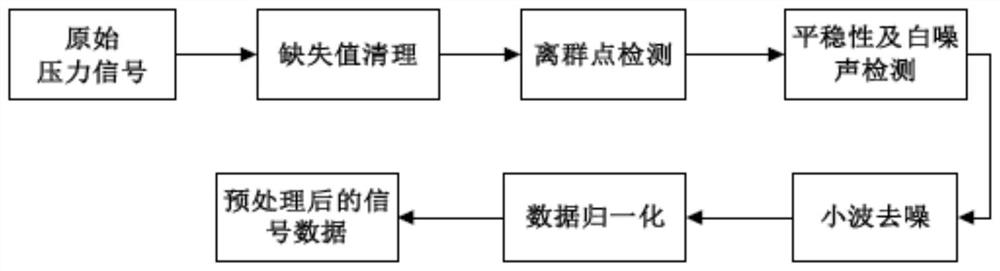

[0095] see Figure 8 In the following, the present invention will be further described in detail with an embodiment, based on the collected original data signal measured by the pressure sensor of the tube expander, and based on the fault diagnosis method proposed by the present invention to realize the fault diagnosis of the tube expansion process .

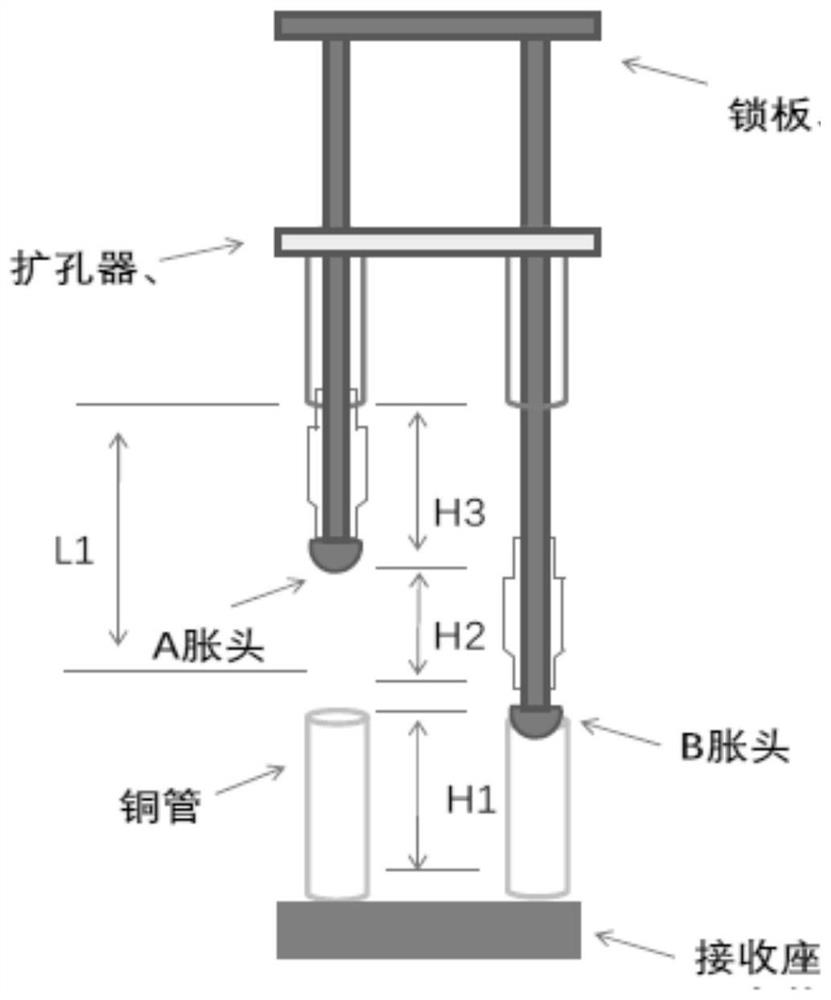

[0096] 1. Explanation of expansion tube data

[0097] Utilizing the results of qualitative analysis of tube expansion equipment, nine fault states related to key components are respectively introduced through specific fault equipment, and the tube expansion process under this fault condition is collected through a special pressure sensor installed on the equipment receiving seat The pressure signal of the middle expansion rod, and corresponding to the ten types of expansion tube failures shown in Table 1, and then affix corresponding labels. At the same time, the data is divided into two parts, 83.3% are randomly selected as th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com