Metal shell battery lead welding method

A technology of tab welding and metal battery, applied in battery pack parts, non-aqueous electrolyte battery, electrolyte battery manufacturing and other directions, can solve the problems of low yield and difficult process, achieve high product yield and improve production efficiency , the effect of convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

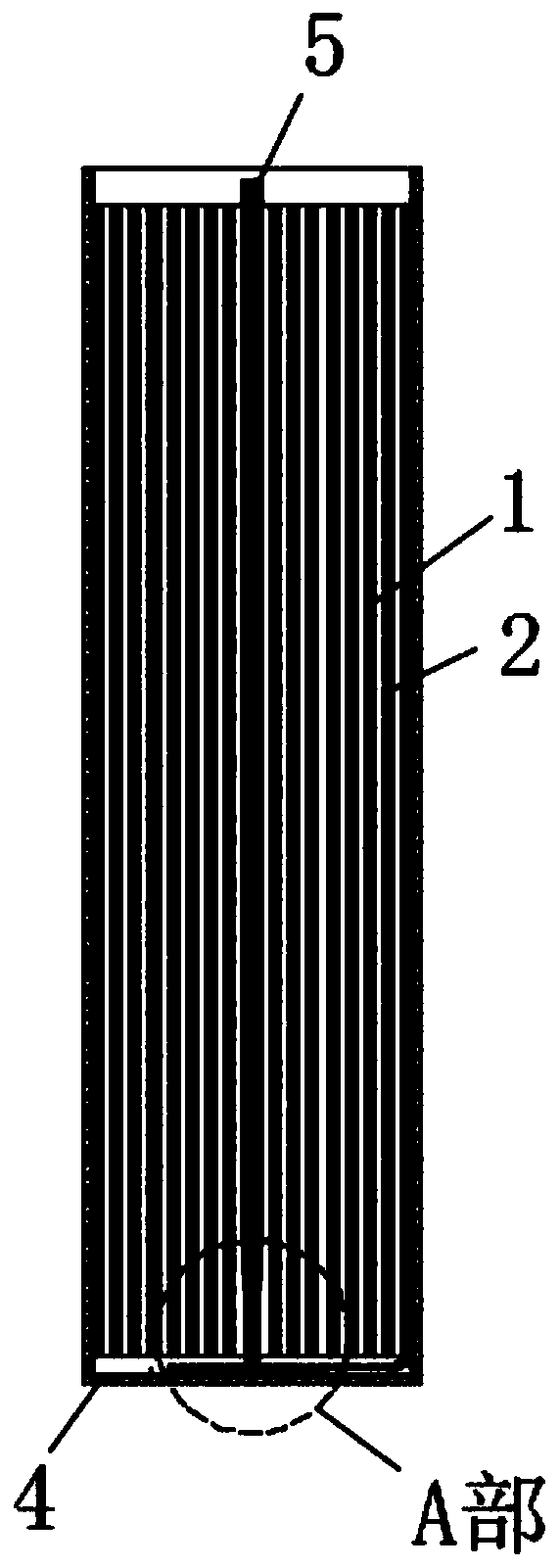

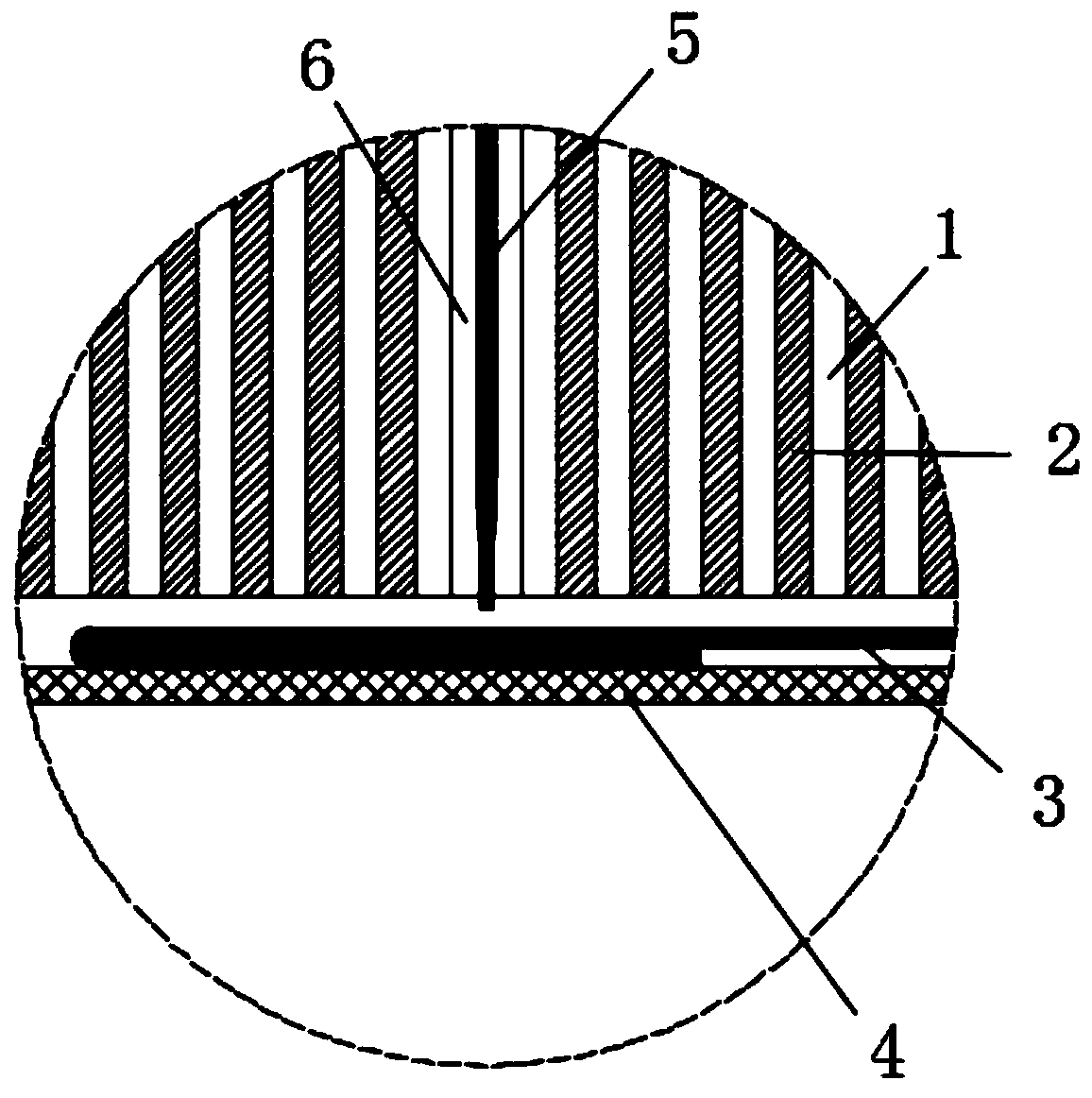

[0027] Please refer to Figure 5 and Figure 6 , In this embodiment, the 18650 battery is taken as an example to illustrate the application of the tab welding method of the metal shell battery provided by the present invention in the tab welding of the 18650 battery. The battery includes a metal battery casing 4, a positive electrode sheet 1, a negative electrode sheet 2, and a tab 3. The positive electrode sheet 1 and the negative electrode sheet 2 are stacked to form a battery cell. The battery casing 4 includes a negative electrode casing and a positive electrode casing. The tab 3 includes a positive tab and a negative tab, both of the positive shell and the negative shell are metal shells, and the welding method of the tab 3 includes the following steps:

[0028] (1) The electric core is placed in the metal battery casing 4;

[0029] (2) Bend the positive tab once and place it between the cell and the positive case, bend the negative tab once and place it between the cel...

Embodiment 2

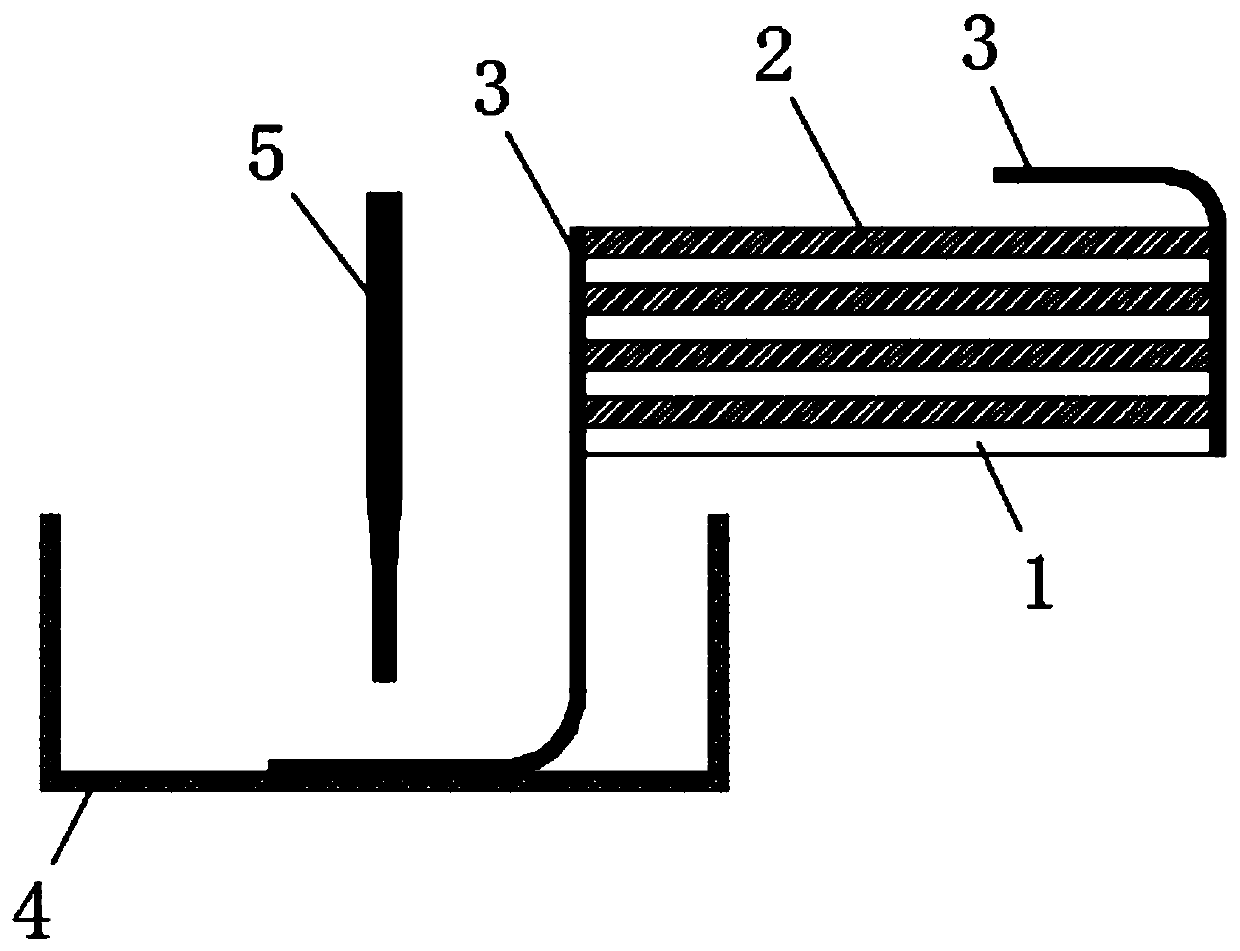

[0035] Please refer to Figure 7 and Figure 8 , In this embodiment, a button battery is taken as an example to illustrate the application of the tab welding method of a metal shell battery provided by the present invention in the tab welding of a button battery. The battery includes a metal battery casing 4, a positive electrode sheet 1, a negative electrode sheet 2, and a tab 3. The positive electrode sheet 1 and the negative electrode sheet 2 are stacked to form a battery cell. The battery casing 4 includes a negative electrode casing and a positive electrode casing. The tab 3 includes a positive tab and a negative tab, both of the positive shell and the negative shell are metal shells, and the welding method of the tab 3 includes the following steps:

[0036] (1) The electric core is placed in the metal battery casing 4;

[0037] (2) Bend the positive tab once and place it between the cell and the positive case, bend the negative tab once and place it between the cell an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com