Front and back drive continuous-speed-changing hybrid power assembly

A hybrid, front and rear drive technology, used in hybrid vehicles, power units, pneumatic power units, etc., can solve problems such as difficult to achieve and separate driving, and achieve the effect of overcoming many parts, good acceleration, and easy installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

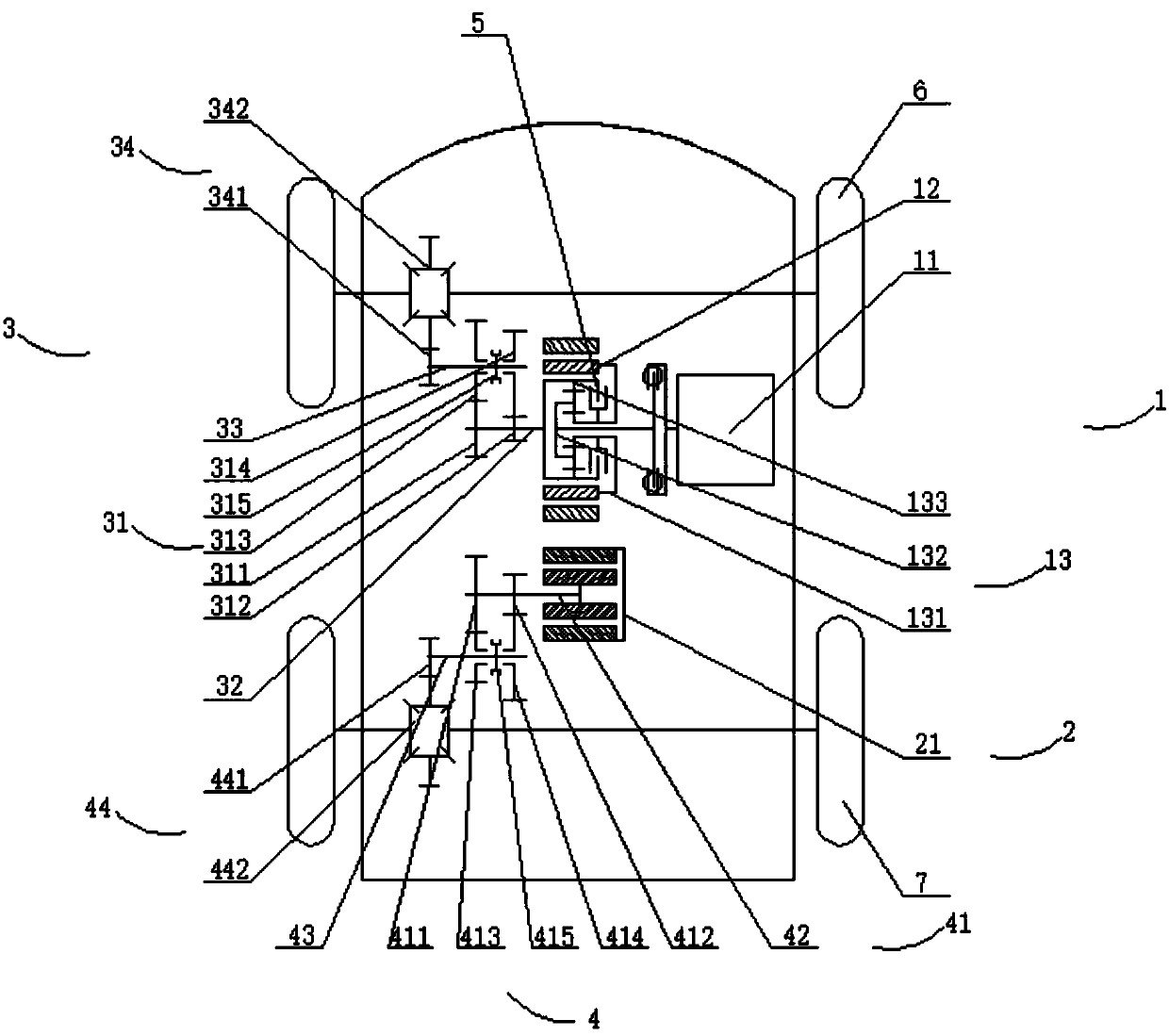

[0035] In order to solve the above technical problems, the present invention discloses a hybrid powertrain with front and rear drive continuously variable speed, see figure 1, the front and rear drive continuously variable speed hybrid powertrain includes a hybrid module 1, a pure electric module 2, a first transmission module 3 and a second transmission module 4, and the hybrid module 1 uses the first transmission module 3 to The power is transmitted to the front wheel 6 of the automobile, and the pure electric module 2 transmits power to the rear wheel 7 of the automobile through the second transmission module 4, and the first transmission module 3 and the second transmission module 4 are independently arranged; as a preferred Yes, the second transmission module 4 and the first transmission module 3 can be designed to have the same transmission structure. Further, the power of the hybrid module and the pure electric module are respectively transmitted through the first transm...

Embodiment 2

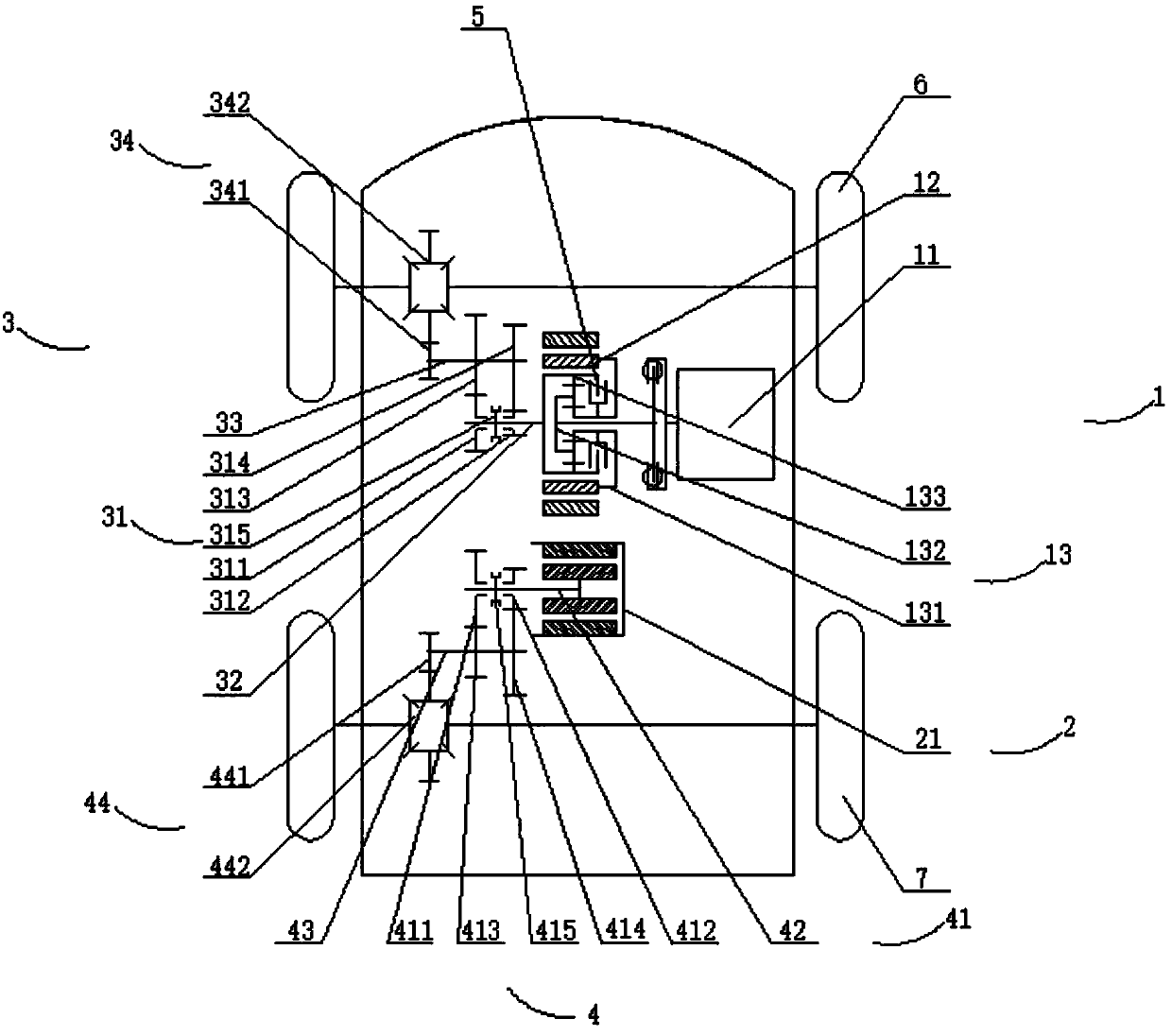

[0067] In this embodiment, the present invention discloses another structure of a front-rear drive continuously variable speed hybrid powertrain, see figure 2 The difference between this embodiment and the first embodiment is that the first gear 311 and the second gear 312 in the first shifting mechanism 31 are set on the first input shaft 32 in a idling manner, and the first The third gear 313 and the fourth gear 314 are fixed on the first output shaft 33, the first shifting element 315 is fixed on the first input shaft 32, and the first shifting element 315 is located on the Between the first gear 313 and the second gear 312 , the third gear 313 is externally meshed with the first gear 311 , and the fourth gear 314 is externally meshed with the second gear 312 .

[0068] At the same time, the sixth gear 411 and the seventh gear 412 in the second shifting mechanism 41 are set on the second input shaft 42 in a idling manner, and the eighth gear 413 and the ninth gear 414 are ...

Embodiment 3

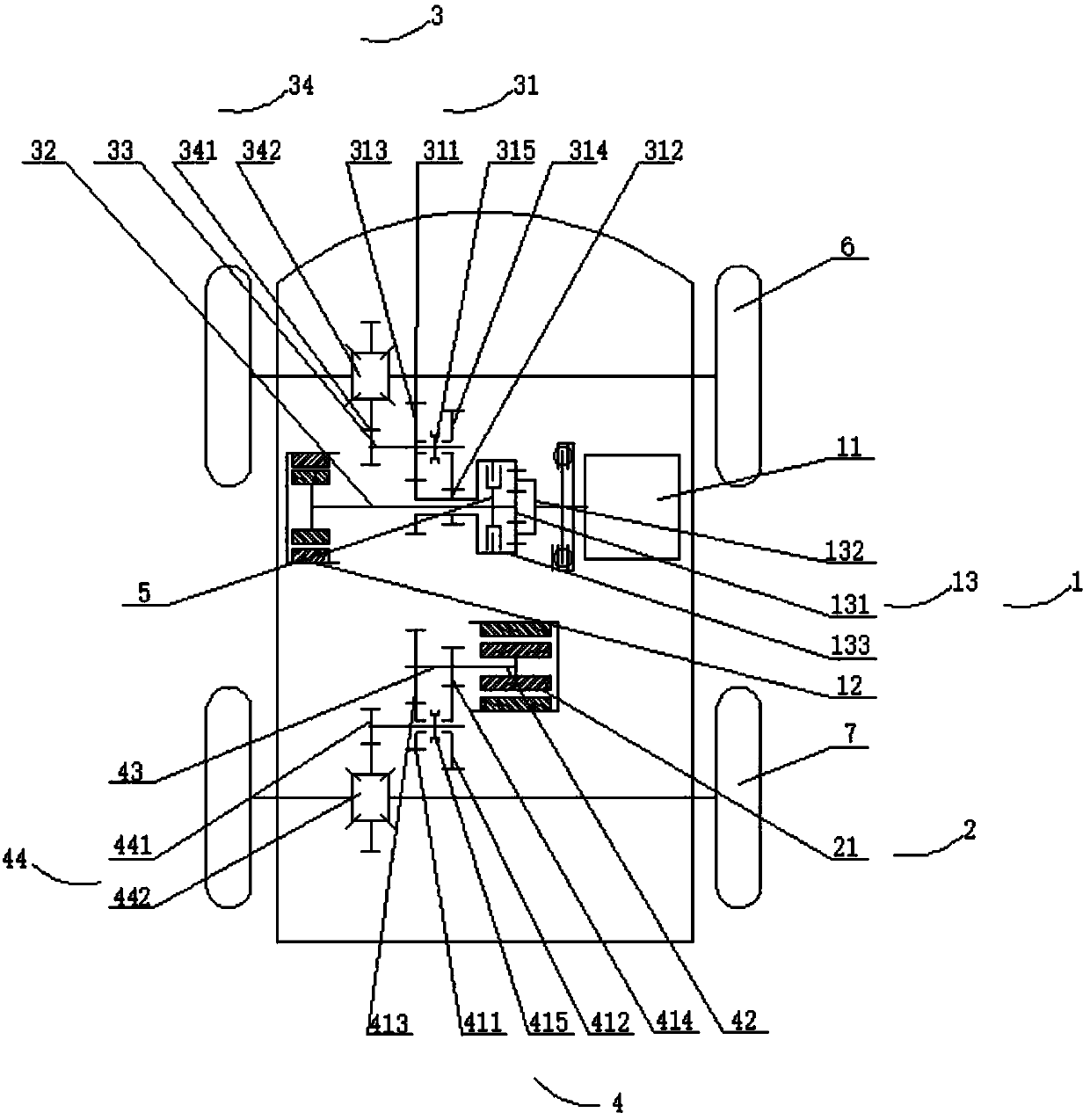

[0071] In this example, see image 3 The difference from Embodiment 1 is that in this embodiment, the first motor 12 and the engine 11 are respectively arranged on both sides of the first transmission module 3 .

[0072] In addition, other technical features of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com