A high-temperature rapid heat treatment process for anti-oxidation of high-frequency resistance welding wire

A high-frequency resistance welding, high-temperature and fast technology, applied in heat treatment furnace, heat treatment equipment, heat treatment process control, etc., can solve the problems of oxygen-free copper wire surface oxidation, large consumption of inert gas, poor protection effect, etc., to achieve good Anti-oxidant protection effect, reduce energy consumption, reduce heat loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

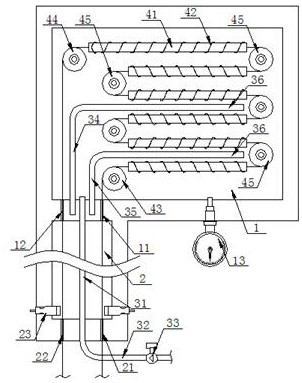

[0025] refer to figure 1 , figure 1 It is a structural schematic diagram of a heat treatment system adopted in a specific embodiment of the present invention.

[0026] This embodiment provides a high-frequency resistance welding wire anti-oxidation high-temperature rapid heat treatment process, including a heat treatment system:

[0027] Such as figure 1 As shown, the heat treatment system includes a heat treatment chamber 1, a transition chamber 2 arranged below the heat treatment chamber 1, and a protective gas delivery pipe. The bottom wall of the heat treatment chamber 1 is provided with an upper wire feeding hole 11 communicating with the top of the transition chamber 2. And the upper wire outlet hole 12, the bottom wall of the transition chamber 2 is provided with the lower wire inlet hole 21 and the lower wire outlet hole 22, and the protective gas delivery pipe includes a vertical preheating section 31 located in the transition chamber 2 and a vertical preheating sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com