A real-time monitoring optical path system for micro-nano structure morphology in inkjet printing

A technology of inkjet printing and real-time monitoring, applied in measurement devices, optical devices, instruments, etc., can solve the problems of reducing printing efficiency, inability to conduct real-time analysis and observation, etc., to achieve convenient and adjustable components, real-time, The effect of low environment dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

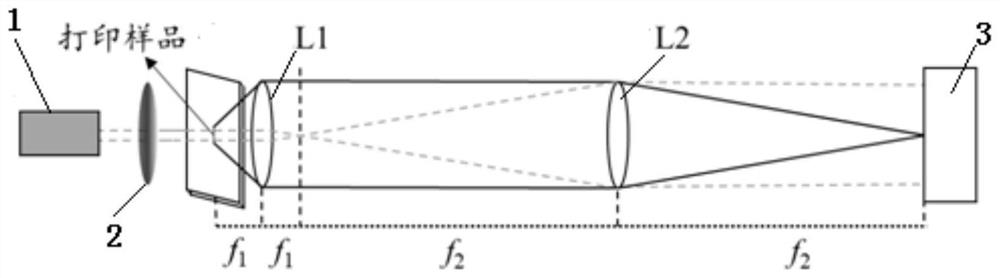

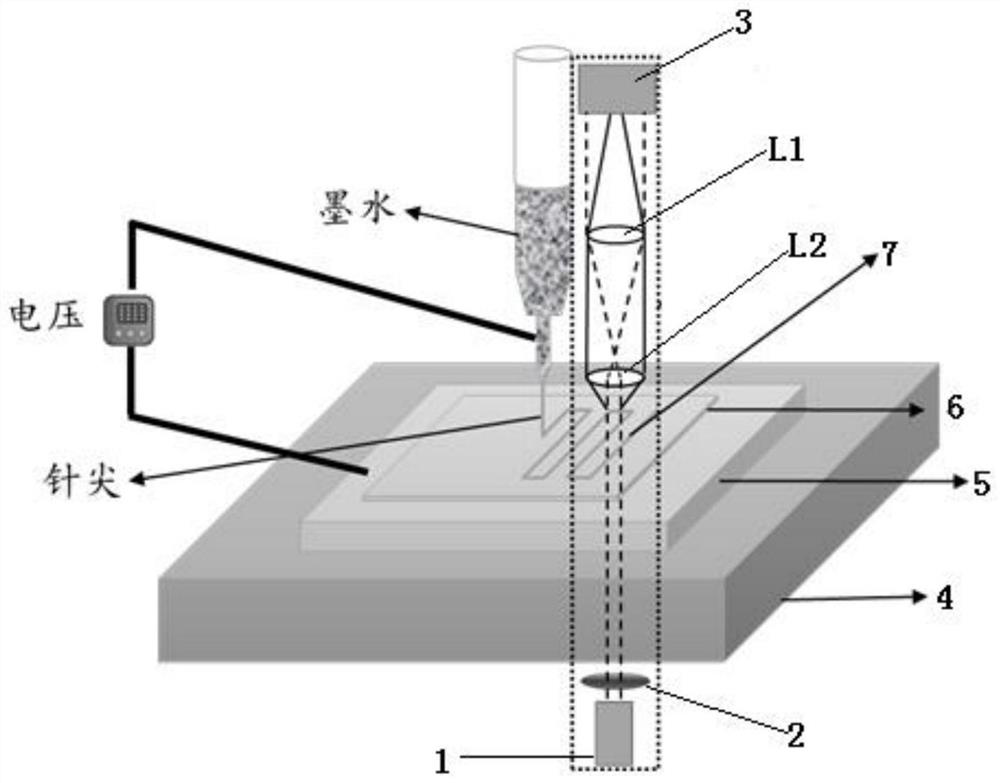

[0017] The main structure of the optical path system for real-time monitoring of micro-nano structure morphology in inkjet printing described in this embodiment is as follows: figure 1 As shown, including laser 1, attenuator 2, first convex lens L1, second convex lens L2 and CCD camera 3, the center of each optical element is located on a straight line, and the surface is perpendicular to the beam propagation direction to ensure uniform beam propagation; printing The distance between the sample and the first convex lens L1 and the focal length f of the first convex lens L1 1 Equal, the distance between the second convex lens L2 and the CCD camera 3 is the same as the focal length f of the second convex lens L2 2 equal, the distance between the first convex lens L1 and the second convex lens L2 is the sum of the focal lengths of the two to ensure that the resulting image is a clear image; the beam emitted by the laser 1 is adjusted by the attenuator 3 to adjust the beam energy,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com