Combined annular mist flow phase-splitting flow measuring method

A flow measurement, combined technology, applied in the direction of detecting the dynamic effect of fluid flow, volume/mass flow generated by electromagnetic effect, volume/mass flow generated by mechanical effect, etc., can solve the problem that cannot fully meet the measurement of annular mist flow requirements, no annular mist liquid film, lack of pertinence, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

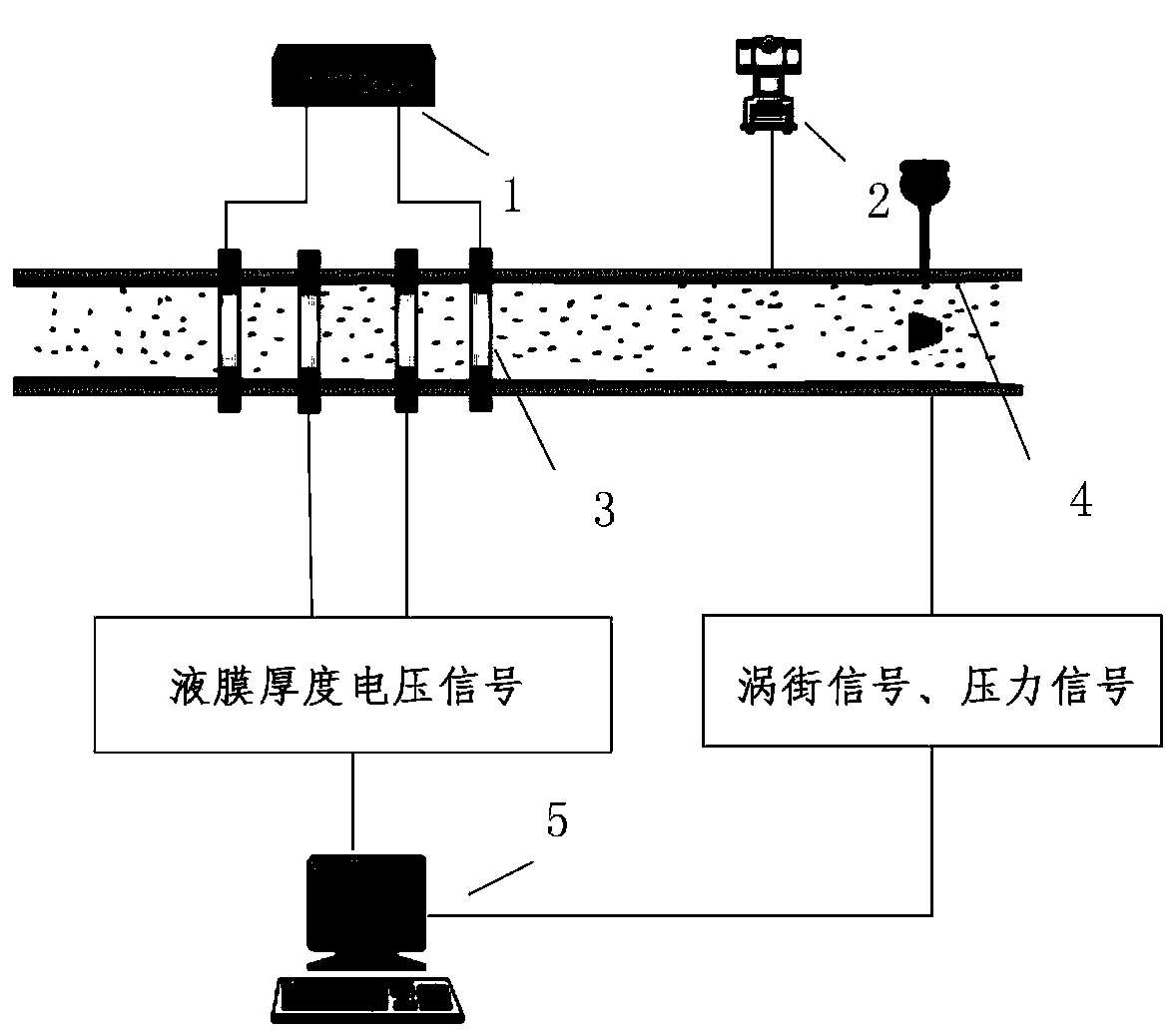

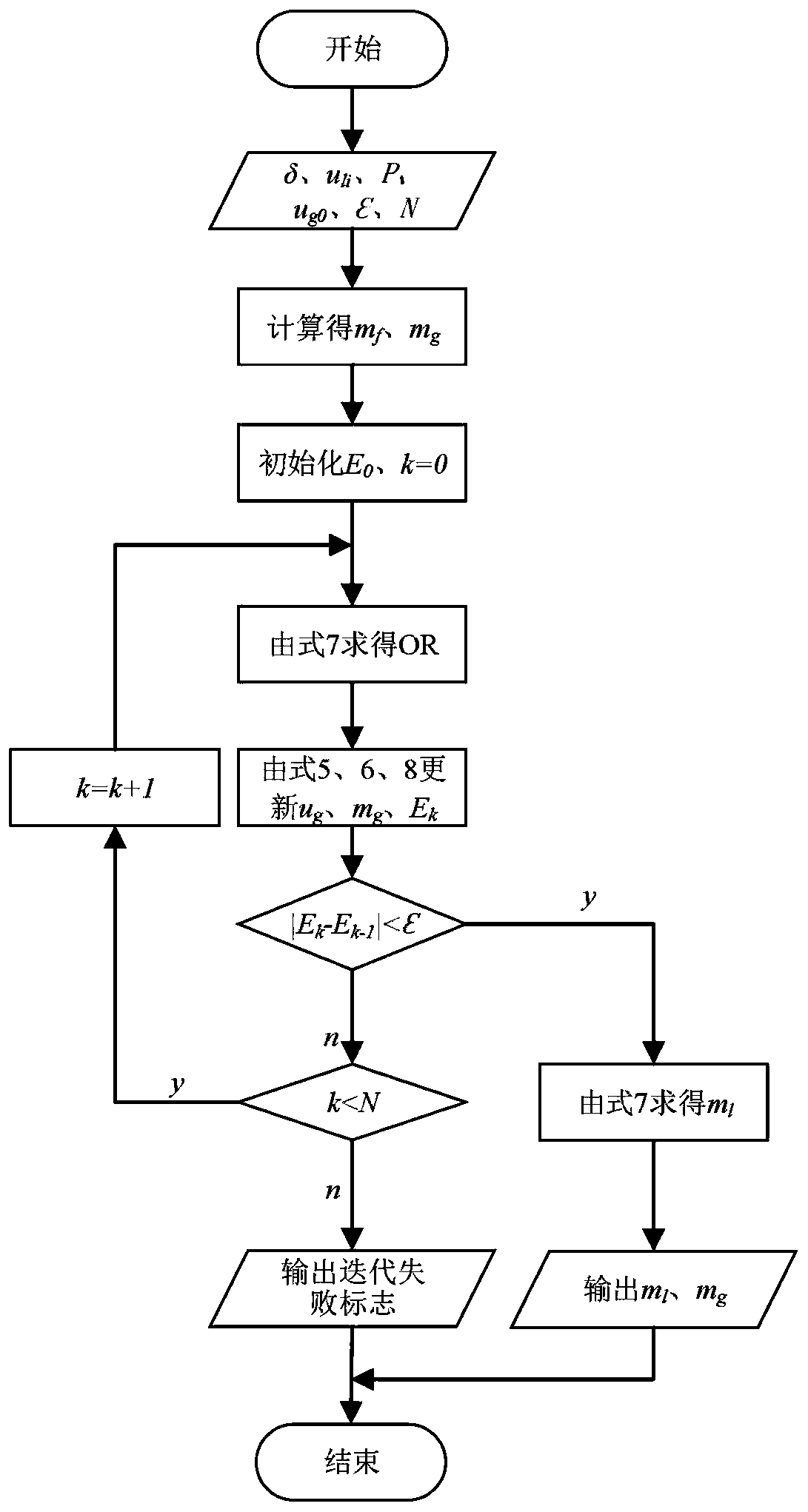

[0043] Measurement process of the present invention passes through following structure (see figure 1 ) Realization: 1 AC excitation power supply, 3 annular conductance sensor, 4 vortex street sensor, 2 pressure sensor and 5 industrial computer. The AC excitation power supply provides carrier signals for the ring electrodes, drives the ring electrodes to generate voltage signals, and converts the liquid film thickness information into voltage. The vortex sensor is used to measure the gas phase flow containing liquid droplets, and the pressure sensor is used to measure the real-time pressure P in the pipeline.

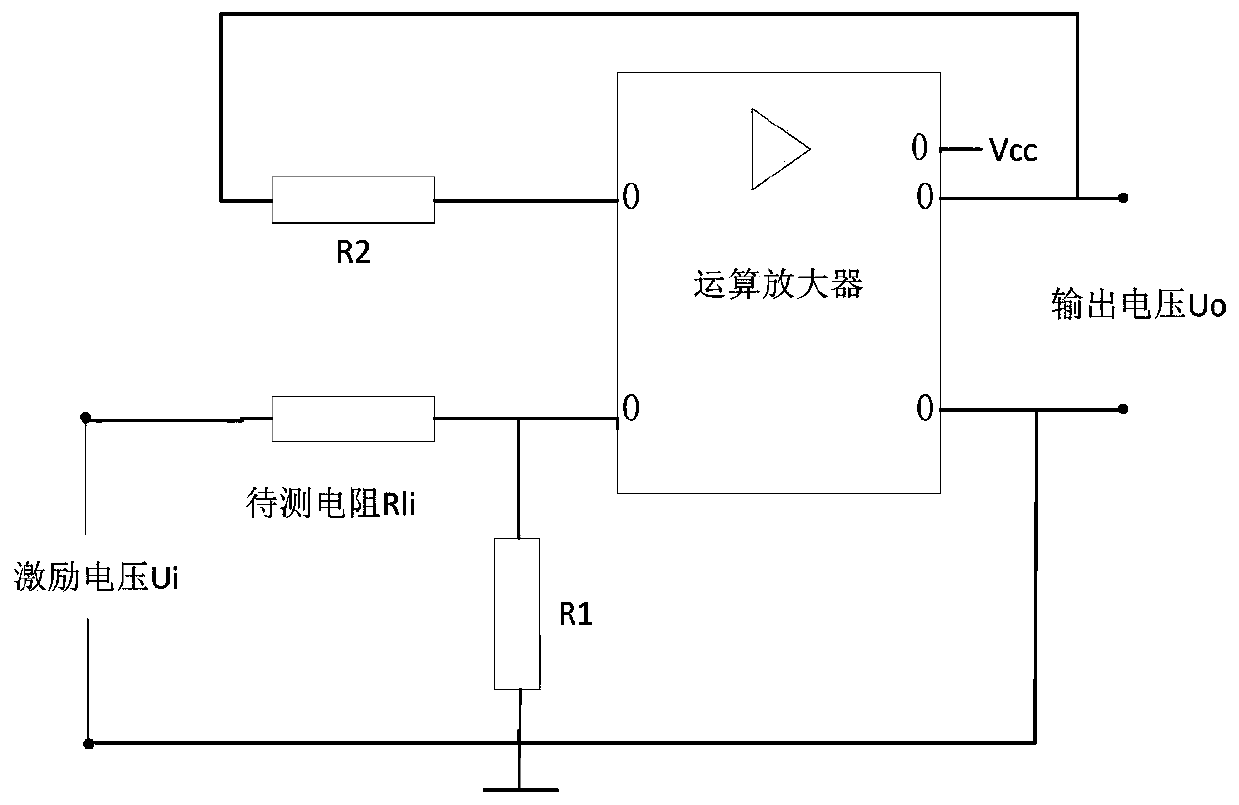

[0044] The conductance sensor that the present invention adopts adopts direct voltage excitation,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com