Planar error detection system

A technology of error system and plane detection, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problem of low measurement accuracy of surface roughness, and achieve the effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

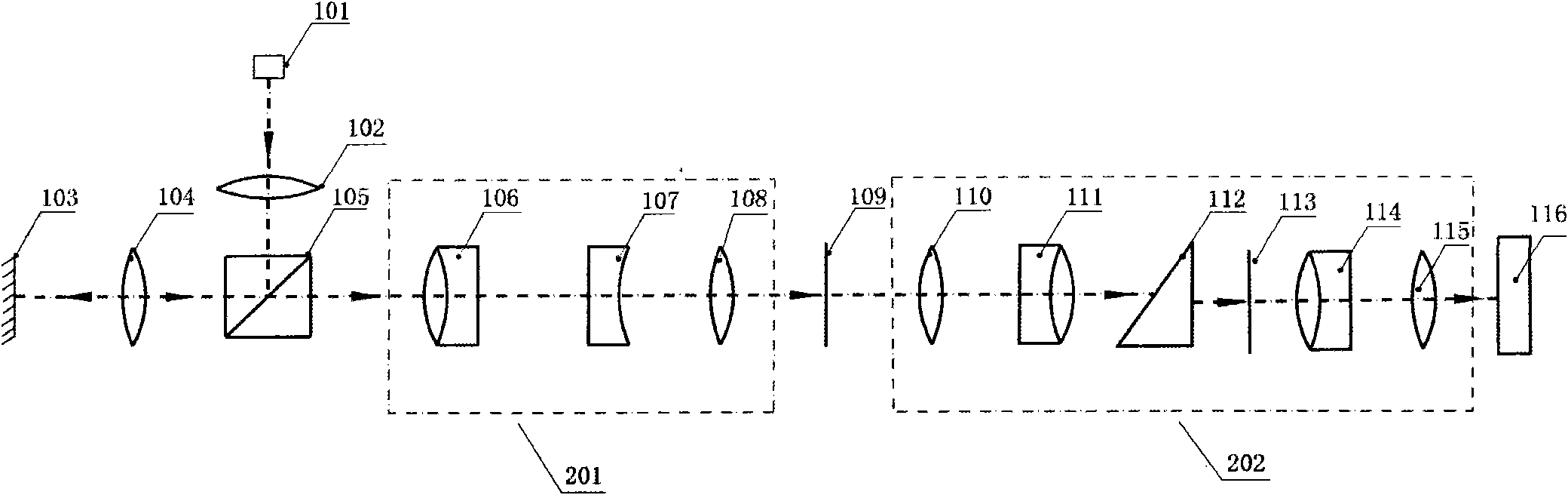

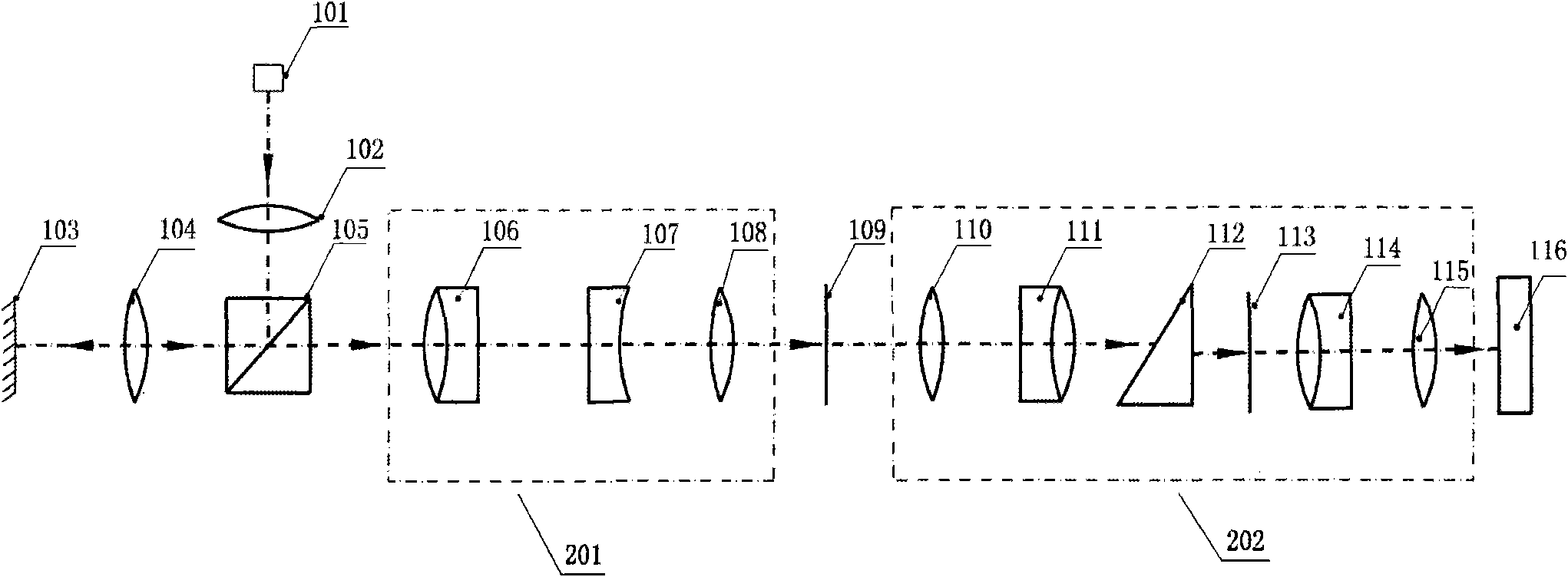

[0010] The optical system proposed by the present invention is a confocal system. Such as figure 1 The schematic diagram of the optical structure of the detection plane error system shown, the system includes an illumination system, an imaging system and a wavelength identification system. The illumination system includes a white light source 101 , an illumination optical system 102 and a half mirror 105 . The imaging system includes an infinity objective lens 104 , a chromatic aberration generating system 201 and a slit 109 . The wavelength identification system includes a spectroscopic optical system 202 and an area array image sensor CCD116. Wherein, the infinity-type objective lens 104 is a kind of infinity-type achromatic objective lens; the chromatic aberration generation system 201 is made up of three groups of lenses 106, 107 and 108; 111 and 114, plus wedge prism 112 and diffraction grating 113 are combined.

[0011] The illumination beam emitted from the white li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com