waterproof led display

An LED display and LED lamp bead technology, which is applied to identification devices, sealed enclosures, instruments, etc., can solve the problem of poor self-cleaning effect and waterproof effect of waterproof LED display, poor substrate bonding force, and low bonding strength of superhydrophobic coating. and other problems, to achieve the effect of improving moisture-proof and anti-corrosion ability, not easy to wear, and good self-cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

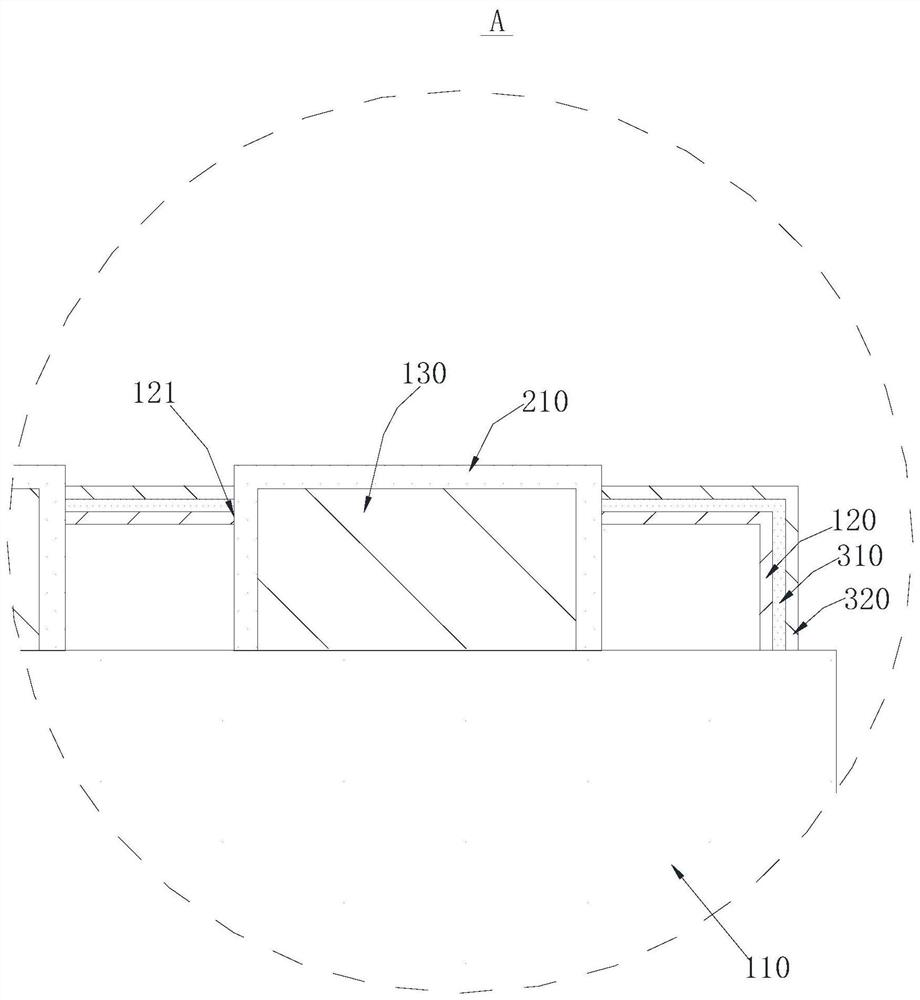

[0089] A two-step method is used to achieve the waterproof effect of the surface of the mask and the surface of the LED lamp. Since the mask itself is attached below the lamp surface, it is not easily damaged by external factors such as friction and impact, so it can protect the super-hydrophobic coating from being damaged. The LED lamp surface is easily affected by external friction, impact, etc., and the nanostructure of the super-hydrophobic coating is easily damaged. Therefore, it is important to realize a hydrophobic coating with good wear resistance on the LED lamp surface.

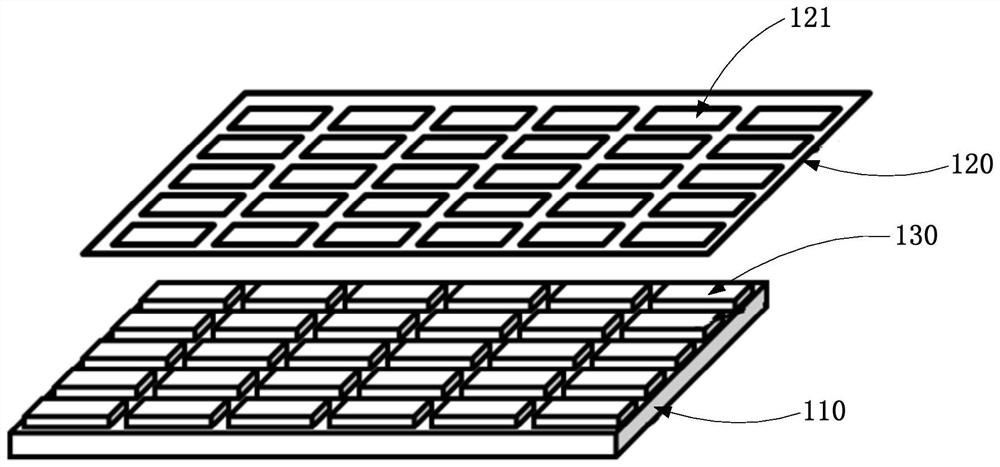

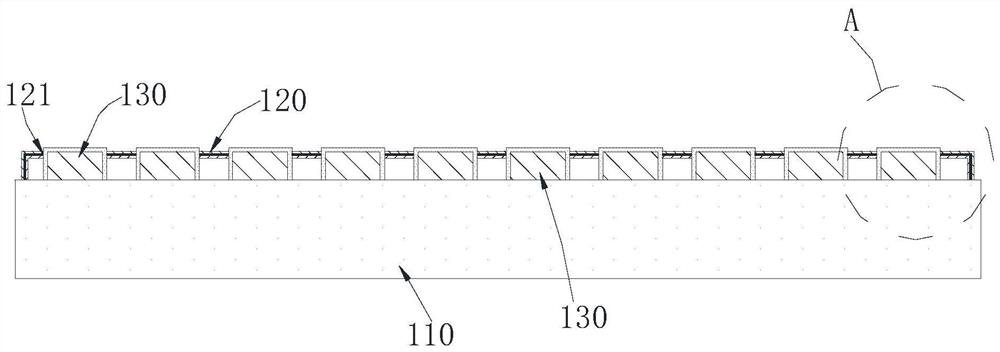

[0090]In the first step of the two-step method, a layer of adhesive is evenly coated on both sides of the plastic mask to form an adhesive layer. layer adhesive. Wherein, the plastic mask includes a grid structure of hollow grids arranged in an array, and the hollow grids are the accommodating holes as described above, which are square grids, and the center-to-center distance of adjacent hollow grid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com