Processing method and application of roses

A processing method, rose technology, applied in the fields of application, tobacco, food science, etc., can solve the hidden safety hazards of smokers and the surrounding people, the lack of cigarette substitutes and other problems, and achieve the effect of good skin, reduced dependence, and skin improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

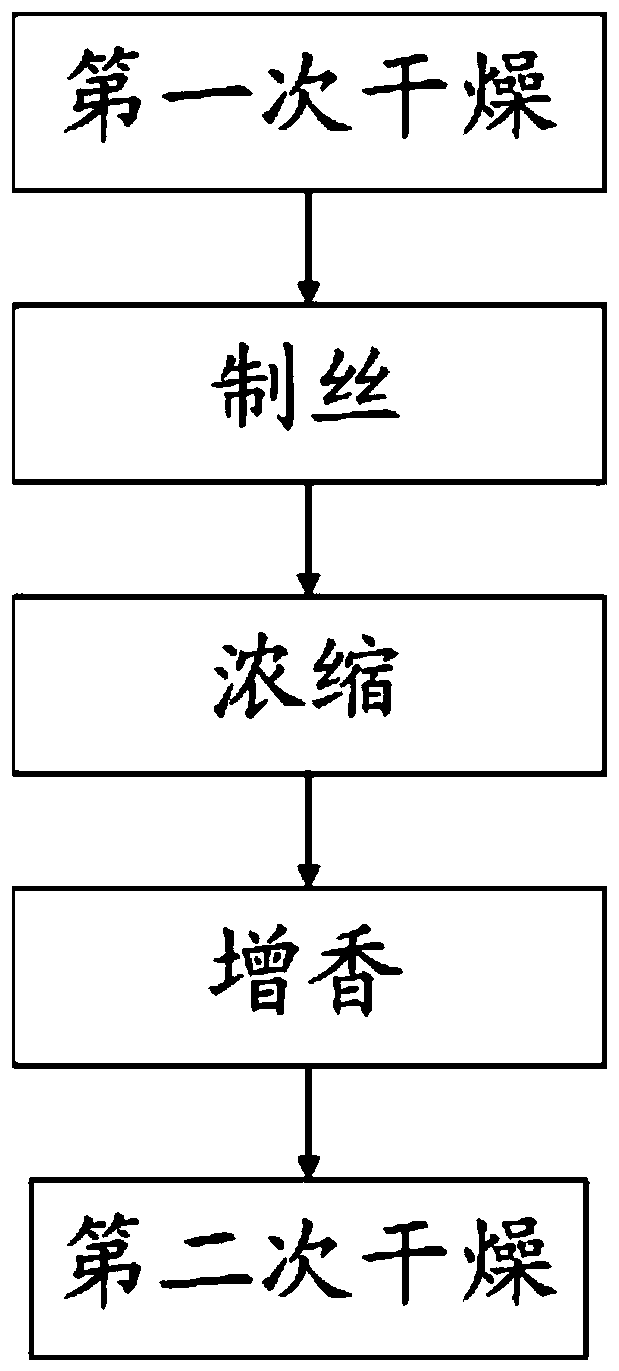

Image

Examples

Embodiment 1

[0029] This embodiment is a specific embodiment for preparing product 1.

[0030] Fresh roses are washed and removed of impurities, crushed through a 200-300 mesh sieve, and dried at 65°C for 30 minutes to obtain the first product 1.

[0031] The first product 1 is threaded to obtain a second product 1 with a width of 0.5-2.3 mm.

[0032] After the fresh roses are washed and removed of impurities, they are crushed and sieved, mixed with water according to the ratio of roses to water of 1:17g / ml, then refluxed and concentrated to obtain the third product 1; wherein, the temperature of refluxed and concentrated is 145°C, and the temperature of refluxed roses is 145°C. Concentration time was 85min.

[0033] Spray the third product 1 on the surface of the second product 1 to obtain the fourth product 1; wherein, the feeding ratio of the third product 1 to the second product 1 is 1.5:1ml / Kg.

[0034] The fourth product 1 is subjected to vacuum freeze-drying to obtain product 1 wi...

Embodiment 2

[0036] This embodiment is a specific embodiment for preparing product 2.

[0037] After washing and removing impurities, the fresh roses are crushed through a 200-300 mesh sieve, and dried at 60°C for 60 minutes to obtain the first product 2.

[0038] The first product 2 is made into filaments to obtain the second product 2 with a width of 0.5-2.3 mm.

[0039] After the fresh roses are washed and removed, they are crushed and sieved, mixed with water according to the ratio of roses to water of 1:15g / ml, and then concentrated by reflux to obtain the third product 2; wherein, the temperature of reflux concentration is 150°C, and the temperature of reflux concentration is 150°C. Concentration time was 80min.

[0040] Spray the third product 2 on the surface of the second product 2 to obtain the fourth product 2; wherein, the feeding ratio of the third product 2 to the second product 2 is 2.5:1ml / Kg.

[0041] The fourth product 2 is subjected to vacuum freeze-drying to obtain pr...

Embodiment 3

[0043] This embodiment is a specific embodiment for preparing product 3.

[0044] Fresh roses are washed and removed of impurities, crushed through a 200-300 mesh sieve, and dried at 80°C for 45 minutes to obtain the first product 3.

[0045] The first product 3 is spun to obtain the second product 3 with a width of 0.5-2.3 mm.

[0046] After the fresh roses are washed and removed, they are crushed and sieved, mixed with water according to the ratio of roses to water of 1:20g / ml, and then refluxed and concentrated to obtain the third product 3; wherein, the temperature of refluxed and concentrated is 120°C, refluxed Concentration time was 100min.

[0047] Spray the third product 3 on the surface of the second product 3 to obtain the fourth product 3; wherein, the feeding ratio of the third product 3 to the second product 3 is 2.2:1ml / Kg.

[0048] The fourth product 3 was subjected to vacuum freeze-drying to obtain a product 3 with a water content of 5-15%. The temperature of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com