A Portable Roof Seam Welder

A seam welding machine and portable technology, applied in the field of seam welding machines, can solve the problems of the influence of welding personnel, low welding efficiency, uneven welding quality, etc., and achieve a high degree of welding automation, improved welding quality, and excellent welding performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is further described in conjunction with the following examples.

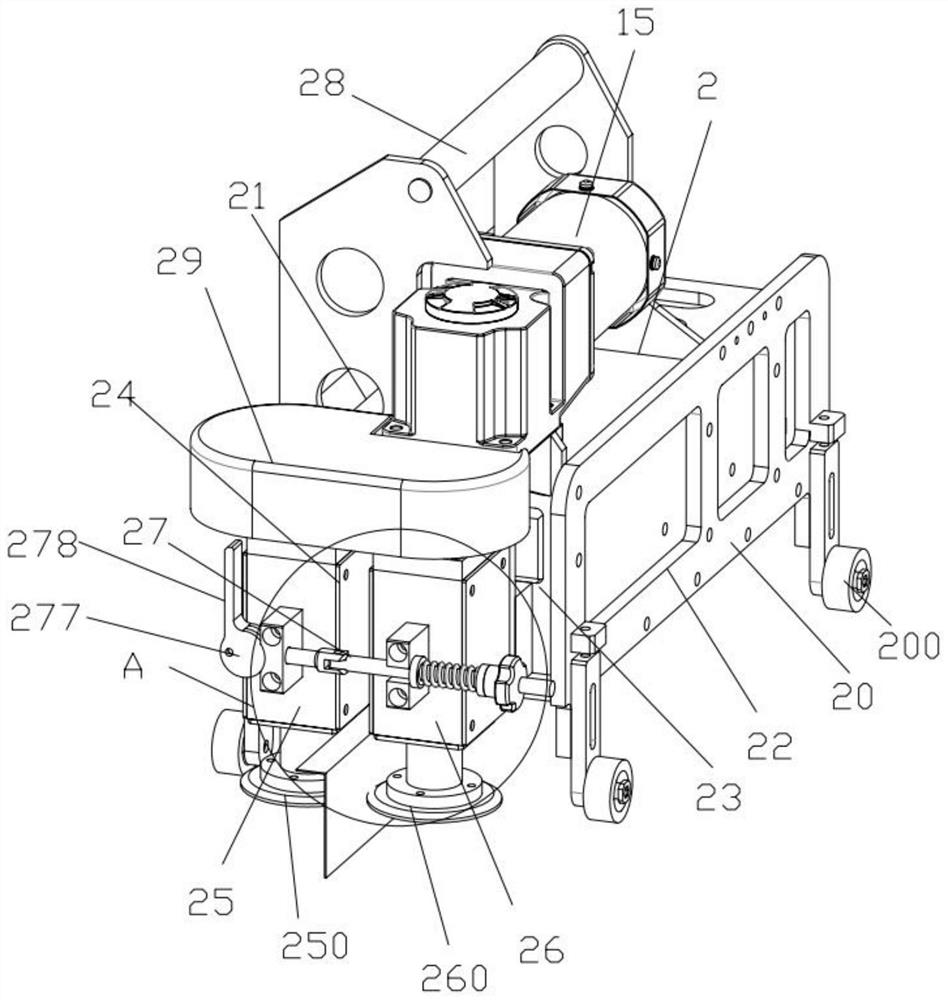

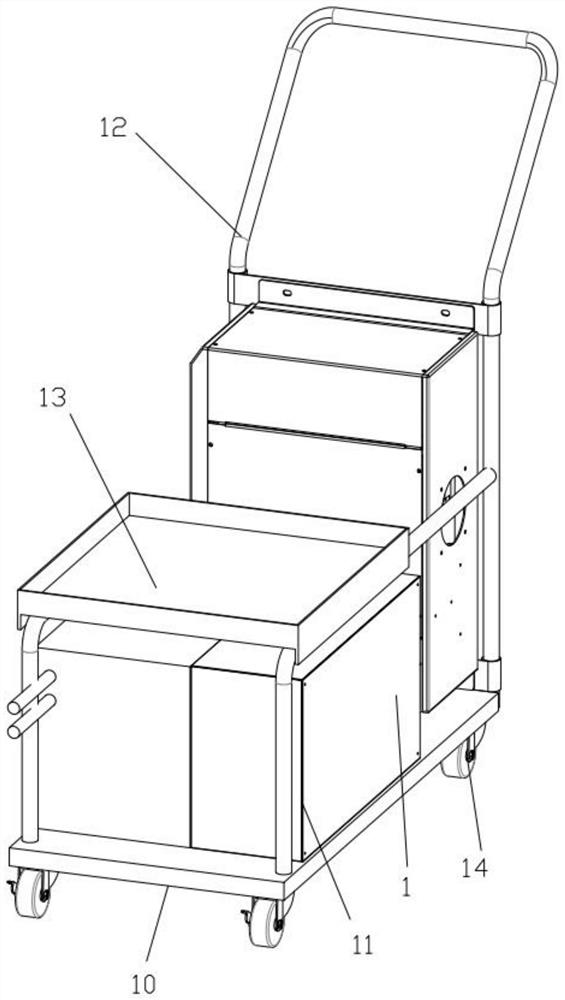

[0025] A specific embodiment of a portable roof seam welding machine of the present invention, as Figure 1-Figure 3 As shown, it includes mutually independent power supply vehicle 1 and welding machine 2. In this embodiment, welding machine 2 and power supply vehicle 1 are independent movable structures, both of which can be electrically connected through lines, and welding machine 2 is small in size. , and only needs the energy provided by the power supply vehicle 1 to realize the welding function alone. The welding machine 2 is not limited by the size and roof space, and the welding is comprehensive and efficient, and the structure is simple and easy to carry.

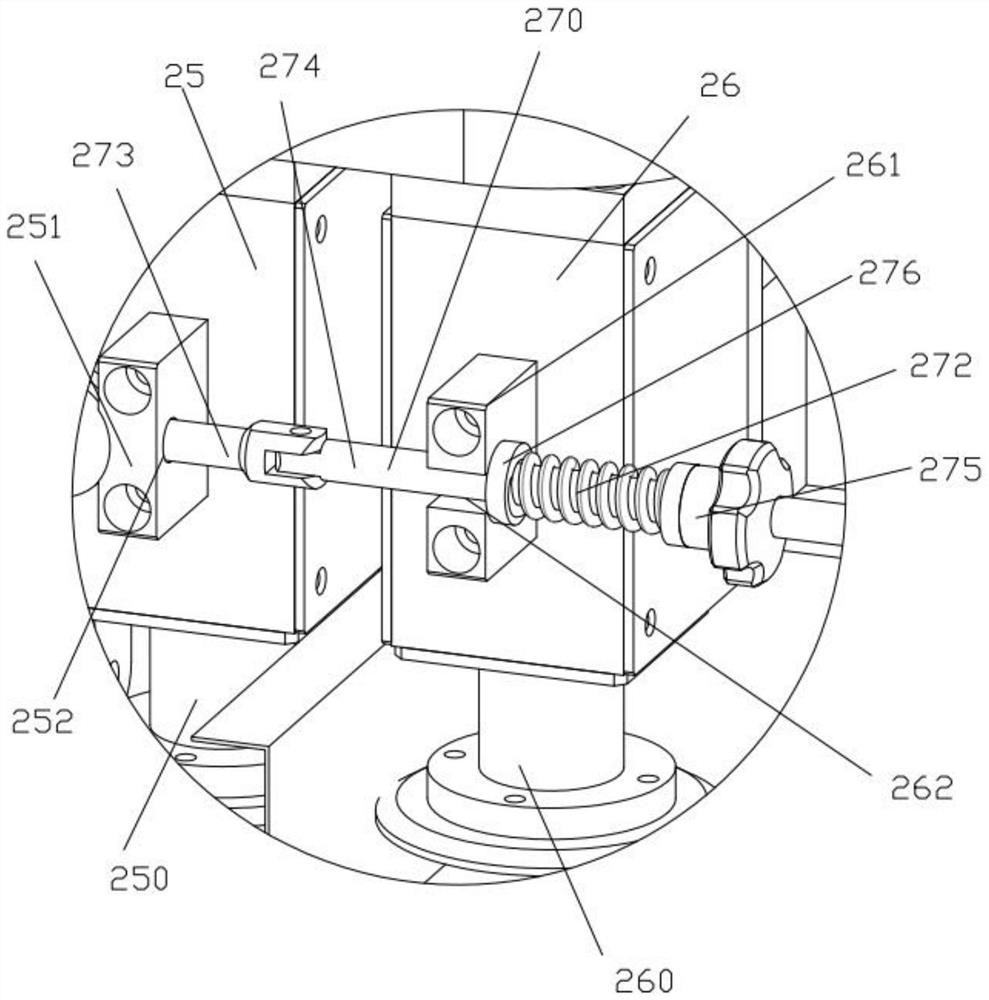

[0026] Welding machine 2 comprises base 20, and the left and right sides of base 20 and the front side are all connected with plate, are respectively left plate 21, right plate 22 and front plate 23, and left plate 21 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com