Novel welding device for producing capacitors

A technology for welding devices and capacitors, which is applied in the direction of capacitors, capacitor manufacturing, auxiliary devices, etc., and can solve the problems of manpower consumption and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

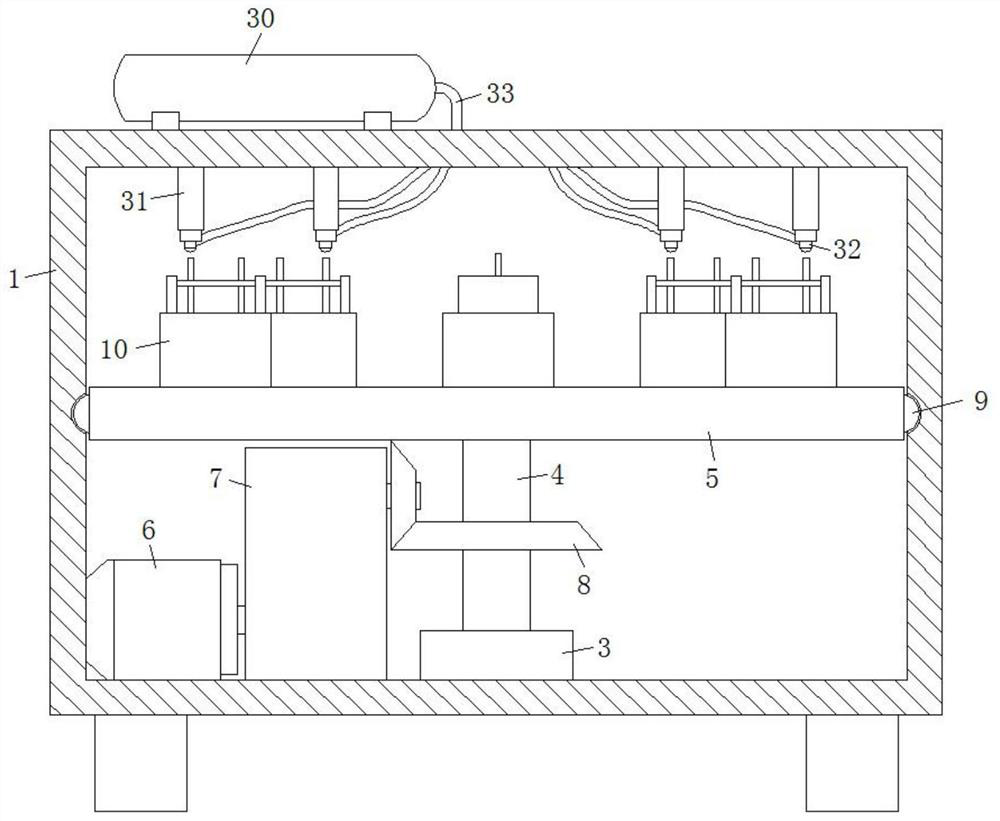

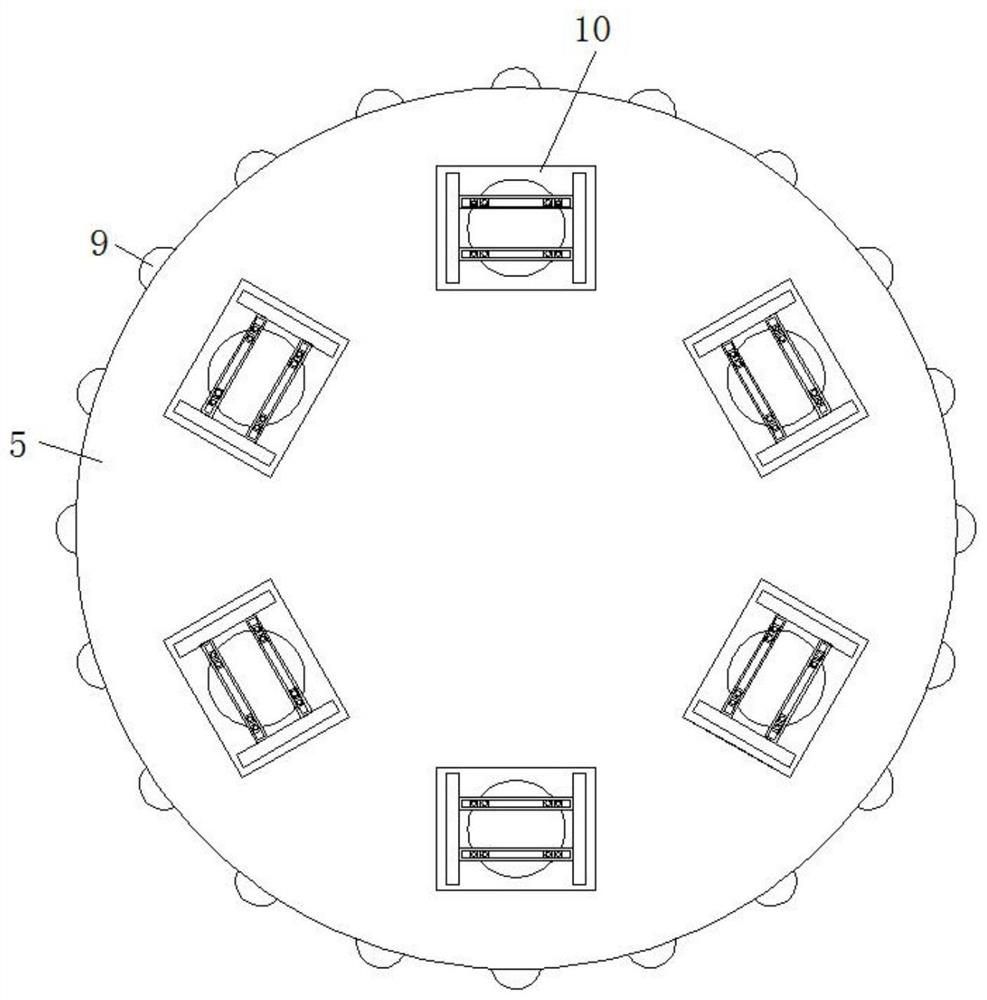

[0030] refer to Figure 1-6 , a new type of welding device for capacitor production, including a processing box 1, the front end of the processing box 1 is connected with a door 2 through hinge rotation, a mounting block 3 is fixed in the middle of the inner bottom of the processing box 1, and the upper end of the mounting block 3 The mounting rod 4 is connected to the rotating bearing through the rolling bearing. The top of the mounting rod 4 is fixed with a holding plate 5. The inner wall of one side of the processing box 1 is also fixed with a servo motor 6. One side of the servo motor 6 is provided with a reducer 7. The output of the servo motor 6 is The end is fixedly connected to the input end of the reducer 7, the output end of the reducer 7 is connected to the installation rod 4 through a bevel gear set 8, the side wall of the holding plate 5 is also equipped with a ball 9, and the inner wall of the processing box 1 There is also a rolling groove in the middle, and the...

Embodiment 2

[0033] Such as Figure 4 and 5 As shown, this embodiment is basically the same as Embodiment 1. Preferably, a bar-shaped groove 27 is provided on the top surface of the support plate 17, and the bar-shaped groove 27 communicates with the chute, and the upper end of the slider 18 is also fixed with a fixed rod 28 , the fixed rod 28 is slidably connected in the bar-shaped groove 27, and the upper end of the fixed rod 28 extends to the outer wall of the support plate 17 and is screwed to the limit block 29.

[0034] In this embodiment, a fixed rod 28 is fixed on the upper end of the slider 18, and a limit block 29 is fixed on the upper part of the fixed rod 28, so as to realize the temporary fixation of the slider 18, thereby ensuring that the temporary fixation of the capacitor is more stable, which is very good. It guarantees the quality of capacitor welding.

Embodiment 3

[0036] Such as figure 2 and 3 As shown, this embodiment is basically the same as Embodiment 1. Preferably, multiple balls 9 are provided and evenly distributed on the side wall of the holding plate 5 .

[0037] In this embodiment, a plurality of balls 9 are arranged on the side wall of the containing plate 5, so that the rotating of the containing plate 5 is more stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com