A parameter selection method to solve the salivation phenomenon of ceramic slurry 3D printing

A ceramic slurry, 3D printing technology, applied in the field of ceramic 3D printing, can solve the problems of high resistance of ceramic slurry, inability to extrude stably, salivation, etc., achieve continuous and stable extrusion, solve salivation phenomenon, reduce salivation The effect of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

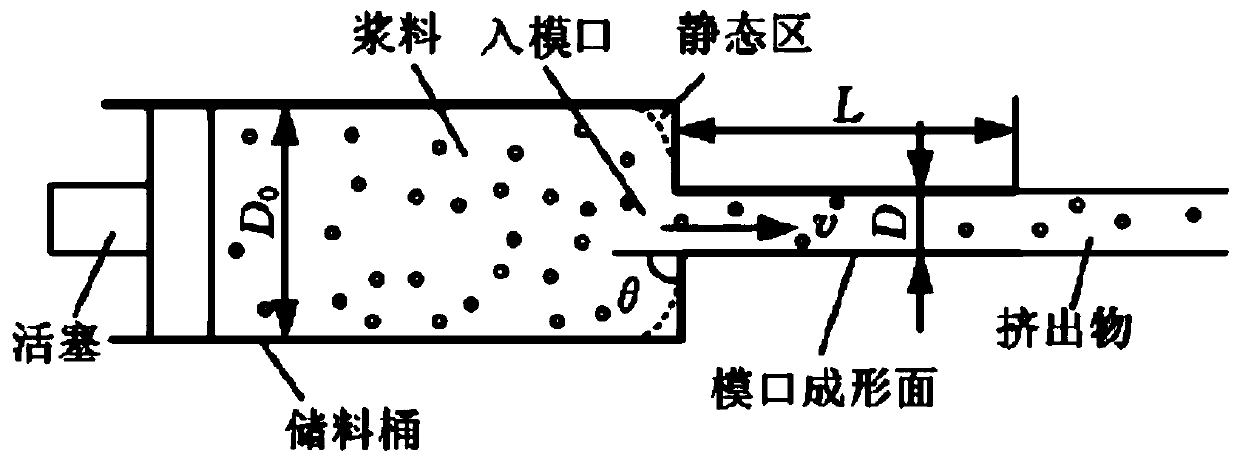

[0047] In the zirconia slurry microflow extrusion 3D printing equipment, the extrusion speed of the ceramic slurry has been determined, which is 0.4mm / s, and the optional diameter models of the extrusion head are 14G, 15G, 18G, 20G, 21G, 22G and 23G, length models are 0.25", 0.5", 1.0" and 1.5"; barrel diameter models are 55cc, 100cc, 200cc and 300cc.

[0048] Through the above-mentioned optional models, the parameter range of ceramic slurry microfluidic extrusion 3D printing is determined; the parameters are the inner diameter D of the extrusion port, the length L of the extrusion port, and the inner diameter D of the barrel 0 and ceramic slurry extrusion speed v; the lower limit of the range is the minimum value in the model, and the upper limit is the maximum value in the model;

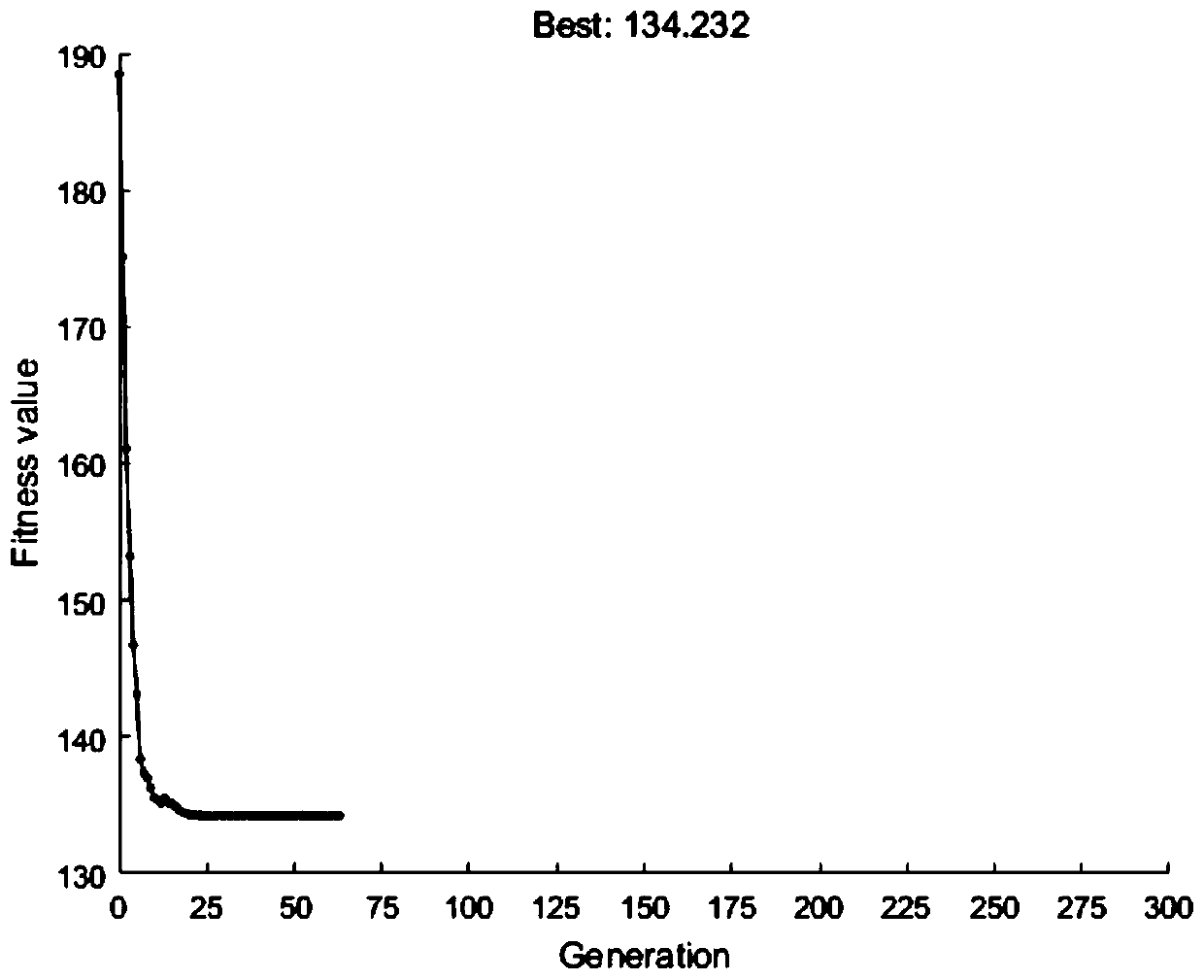

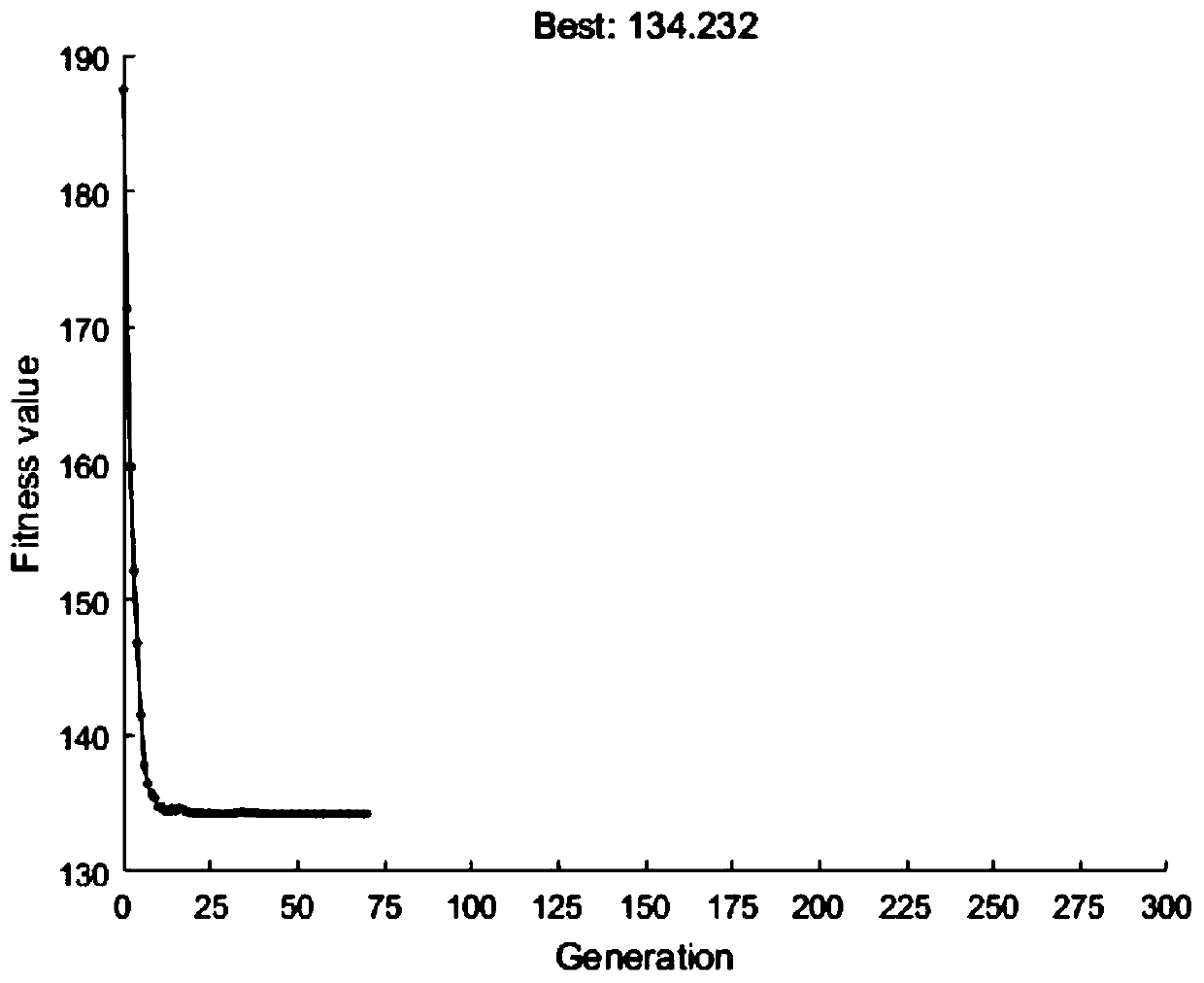

[0049] According to the empirical formula of the Benbow-Bridgwater model of the extrusion resistance of the ceramic slurry, the mathematical model of the extrusion resistance of the ceramic slurry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com