PVC cable material applied to high-fire-retardant environment-friendly CMR grade

A cable material, high flame-retardant technology, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of large influence of hardness, narrow processing temperature, increase of production cost, etc., to improve production efficiency, stable extrusion processing performance, The effect of continuous and stable production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

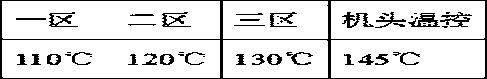

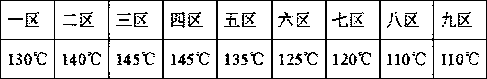

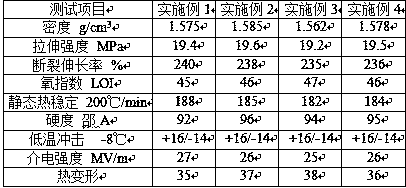

[0022] Examples 1-4: A PVC cable material applied to high flame-retardant and environmentally friendly CMR grades. The heat-resistant hard PVC granules are prepared by an extruder. The heat-resistant hard PVC granules consist of the following parts by weight The composition of the components, as shown in Table 1:

[0023] Table 1

[0024] ;

[0025] The PVC cable material is obtained through the following steps: when the high-speed mixer is mixing the materials, first stir and add PVC resin at a low speed, add stearic acid after 15 seconds and start high-speed stirring, and add phthalic acid when the temperature of the resin reaches 50 degrees After mixing dicyclohexyl ester and epoxy fatty acid methyl ester for 1 minute, add an environmentally friendly phosphorus-nitrogen flame retardant to avoid adding a large amount of liquid at one time to the high-mixer under high-speed stirring and throwing it to the wall of the pot, failing to fully absorb with the resin. Mix, add m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com