Driving integrated type integral wheel

An integrated, wheel-based technology, applied in the direction of electric components, power devices, motion deposition, etc., can solve the problems of high material accuracy and processing methods, unsuitable assembly line modular installation, and large volume of reduction gear, etc., to achieve shortened axial Effects of installation size, compact structure, and simplified parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

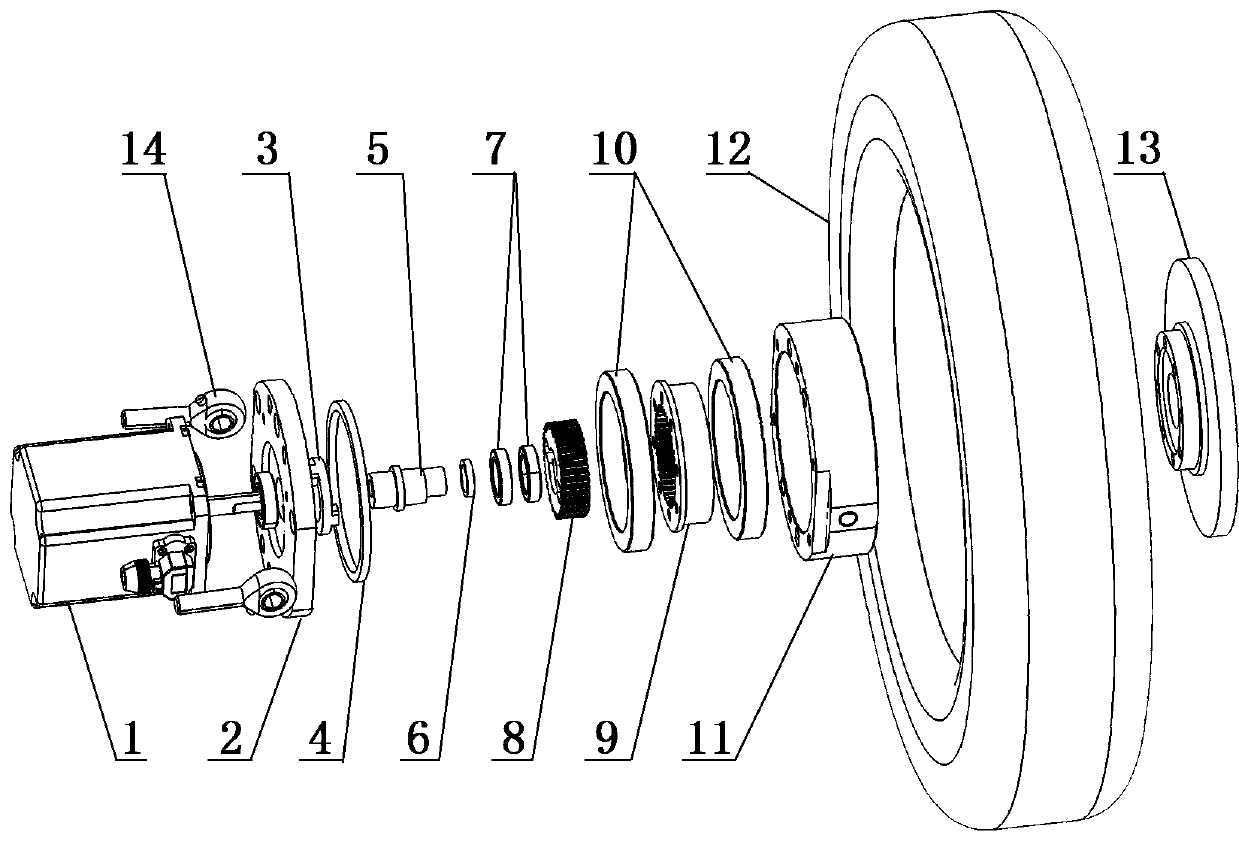

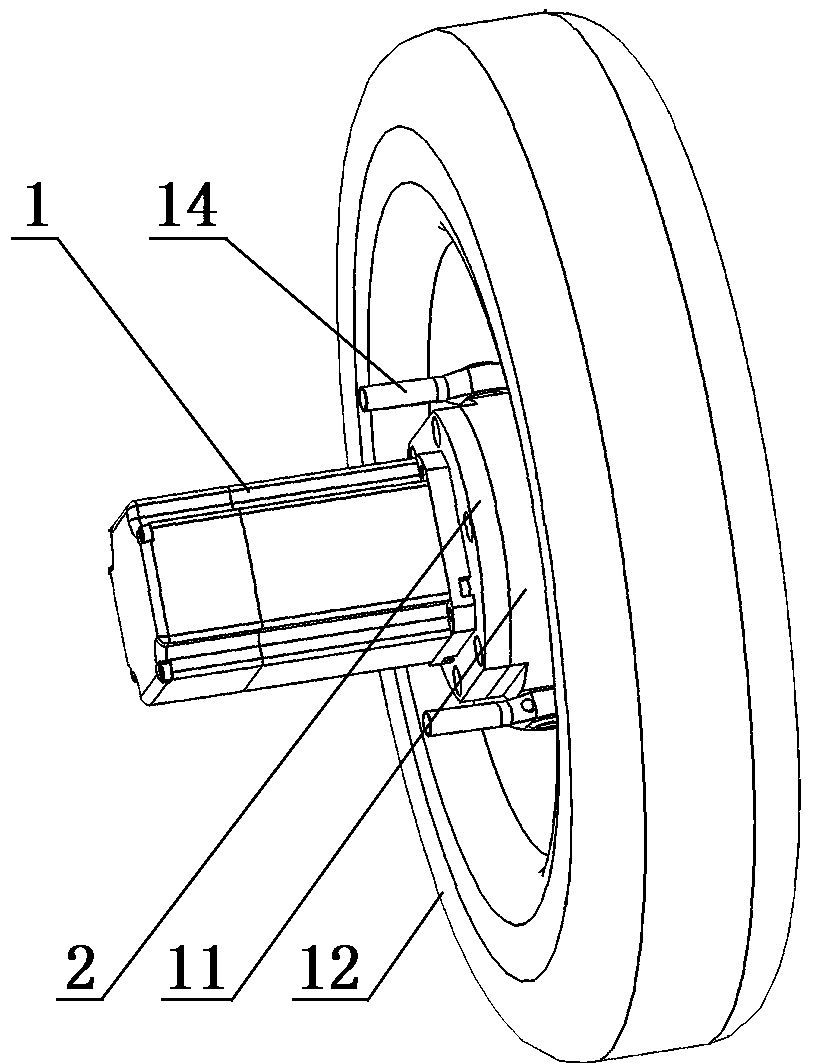

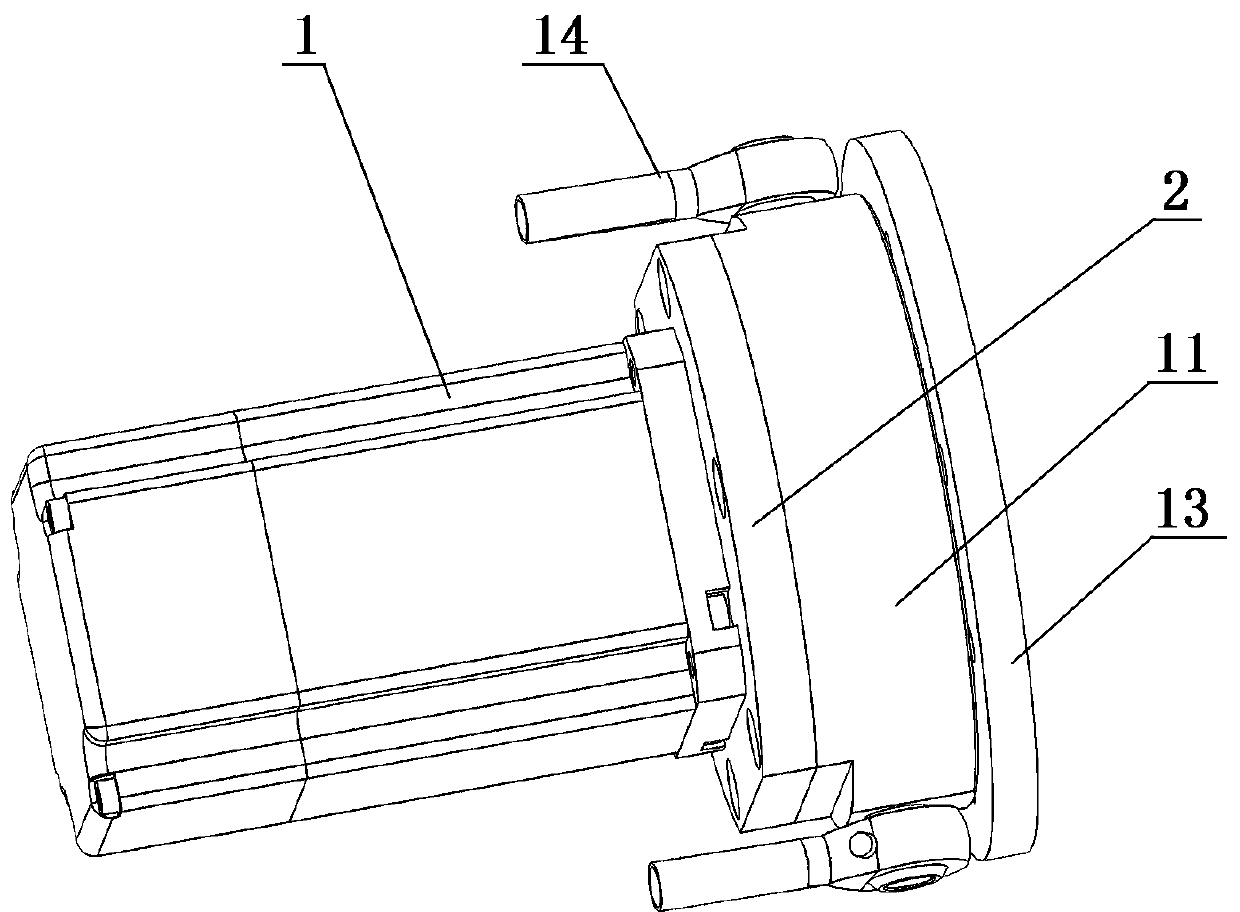

[0033] Such as Figure 1-7 The drive-integrated integrated wheel shown includes a motor module 1, an internal gear reduction module and a wheel module; the internal gear reduction module includes a motor mount 2 and a reduction module shell seat 11 matched with the motor mount 2; the internal gear reduction The module is detachably connected to the motor module 1 through the motor mounting seat 2; the internal gear reduction module is assembled and connected to the wheel module through the reduction module housing seat 11, which is convenient for modular assembly of the drive-integrated wheel. Among them, the motor module 1 adopts a servo motor, which improves the stability of the transmission by taking advantage of the advantages of good precision, strong anti-overload capability and stable low-speed operation of the servo motor itself, and can be applied to the occasion of quick start.

[0034] The internal gear reduction module also includes an eccentric shaft 5 fixedly con...

Embodiment 2

[0043] Such as Figure 8 The schematic diagram of the structure of the four-wheel-drive trolley is shown, and four integrated integrated wheels are mounted on the frame through four suspension yokes 15, which are arranged between the two front wheels and the two rear wheels Steering electric cylinder 16 and connecting rod 17 are arranged, and the steering function of the wheel is realized by steering electric cylinder 16 and connecting rod 17 . The present invention directly connects the wheels by connecting the motor module 1 with the internal gear reduction module, and can realize the configuration of two-wheel drive, three-wheel drive, four-wheel drive or multi-drive, enriches the transmission form, and improves the transmission efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com