Hydraulic braking system of low-floor tramcar

A technology of hydraulic brakes and trams, applied in the direction of brakes, brake transmission devices, vehicle components, etc., can solve the problems of inconvenient operation, long time consumption, inconvenient observation, etc., achieve flexible modular design, convenient The effect of modular design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

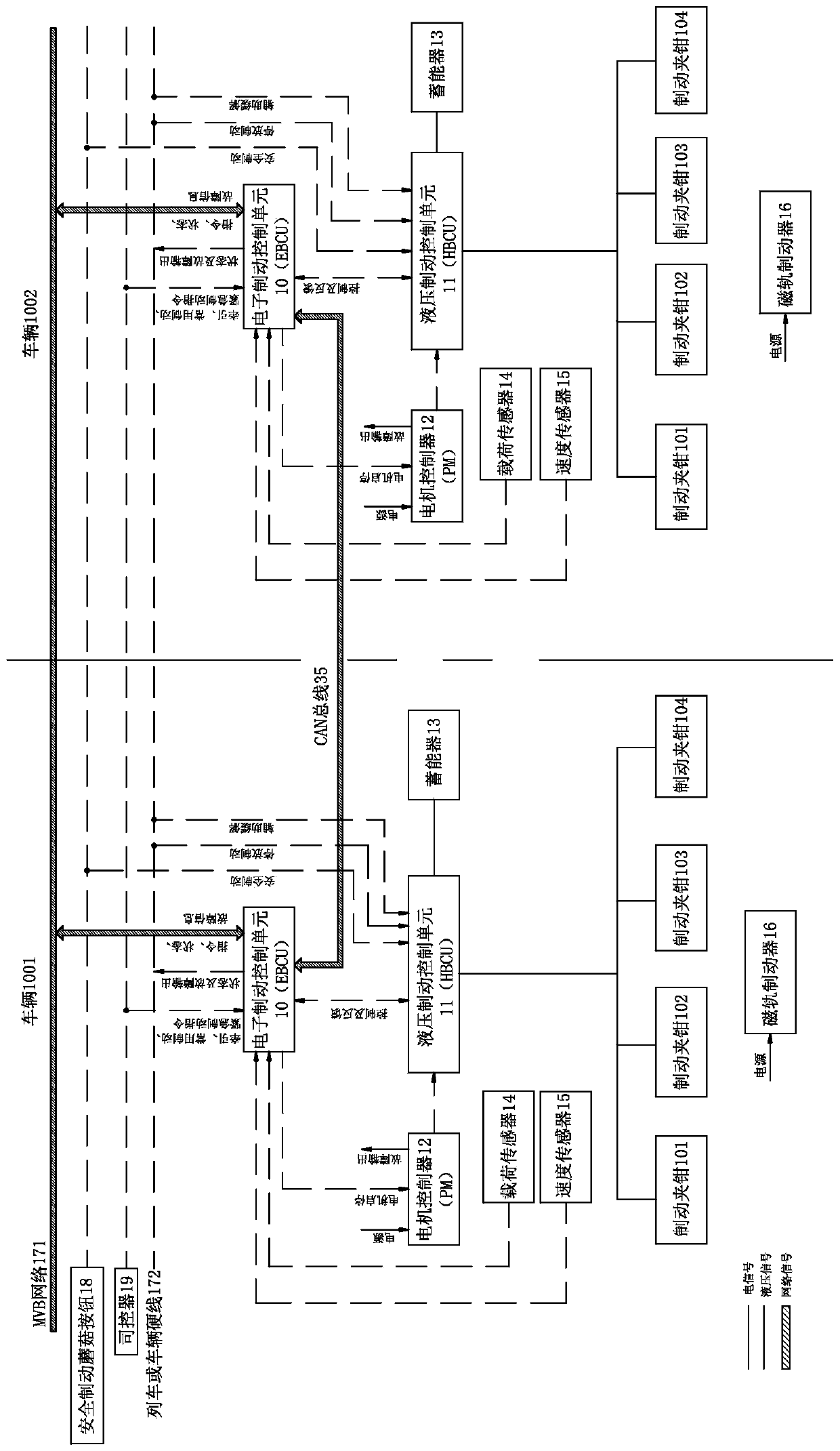

[0046] see figure 1 and figure 2 , The hydraulic brake system 1 of the present invention includes a hydraulic brake control system, a foundation brake device and a magnetic track brake 16 . During the working process, the hydraulic braking system exchanges information with the braking command generation system through the communication system. In this embodiment, two vehicles, vehicle 1001 and vehicle 1002, are used as an example to illustrate it. Of course, according to actual needs, multiple vehicles can be grouped for braking control. The bogie is equipped with a hydraulic brake caliper 101 , a hydraulic brake caliper 102 , a hydraulic brake caliper 103 and a hydraulic brake caliper 104 . Since the structures of the braking systems on the two vehicles are the same, in the following description, only the braking system on the vehicle 1001 is taken as an example for illustration. The hydraulic brake caliper can be either a shaft-disc brake or a wheel-disc brake.

[0047]...

Embodiment 2

[0066] As the description of Embodiment 2 of the present invention, only the differences from Embodiment 1 above will be described below, that is, the structure of the hydraulic station in the hydraulic control unit will be mainly described.

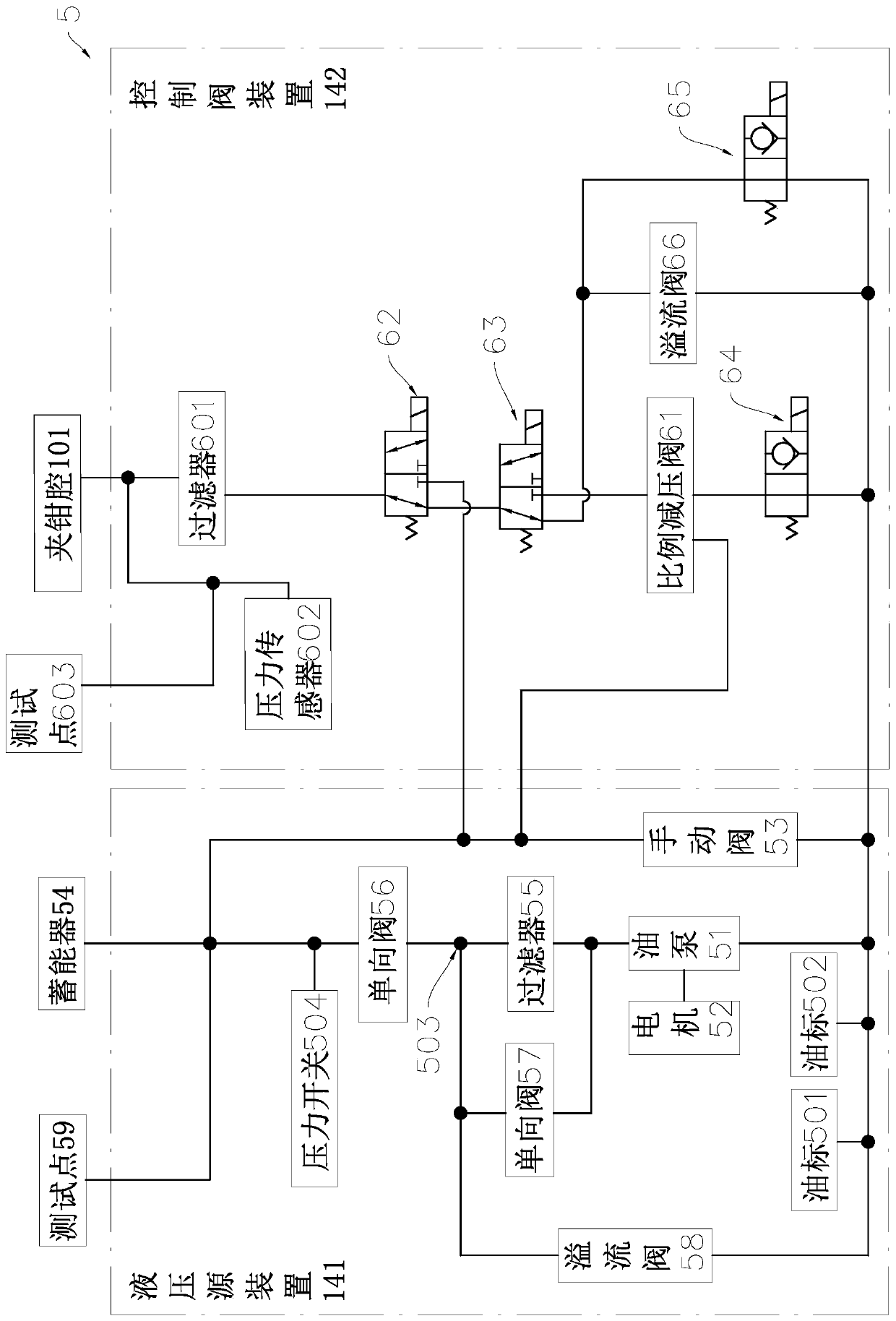

[0067] see Figure 3 to Figure 7 , the hydraulic station 5 includes an installation housing 7, a hydraulic source device 141 and a control valve device 142; wherein, the valve device 142 is used to carry out the process of supplying hydraulic oil from the hydraulic source device 141 to the clamp chamber 10 of the hydraulic brake caliper control.

[0068] Such as Figure 3 to Figure 7 As shown, the hydraulic source device 141 includes an oil tank, an oil pump 51 , an oil pump driving motor 52 , a manual valve 53 , an accumulator 54 , a filter 55 , a check valve 56 , a check valve 57 and a relief valve 58 . Along the traveling direction of the hydraulic oil in the oil circuit, the oil pump 51, the filter 55 and the one-way valve 56 are s...

Embodiment 3

[0087] As the description of Embodiment 3 of the present invention, only the differences from Embodiment 1 or Embodiment 2 will be described below, that is, the structure of the suspension device in the magnetic rail brake will be mainly described.

[0088] see Figure 8 to Figure 10 The magnetic track brake 3 of the present invention includes a suspension bracket 310, a suspension device 311 and a brake electromagnet (not shown in the figure), the brake electromagnet is suspended on the suspension bracket 310, and the two ends of the suspension bracket 310 are connected by the suspension device 311 Suspended on the bogie mounting bracket 301, so that the brake electromagnet is arranged between the two wheels on the same side and suspended above the rail.

[0089] Such as Figure 8 to Figure 10 As shown, the suspension device 311 includes a suspension sleeve 32 , a limit sleeve 33 , a boom 34 , a return spring 312 , a lock nut 35 , a dust cover 36 , a joint seat 315 and a joi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com